A composition for engine low-alcohol gasoline additive and its preparation method

A gasoline additive and composition technology, applied in the field of engine low-alcohol gasoline additive composition and its preparation, can solve problems such as difficulty in starting the engine, affecting vehicle power performance, human and environmental pollution, etc., and achieves improvement of low-temperature cold start, reduction of The effect of gas explosion and streamlined equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

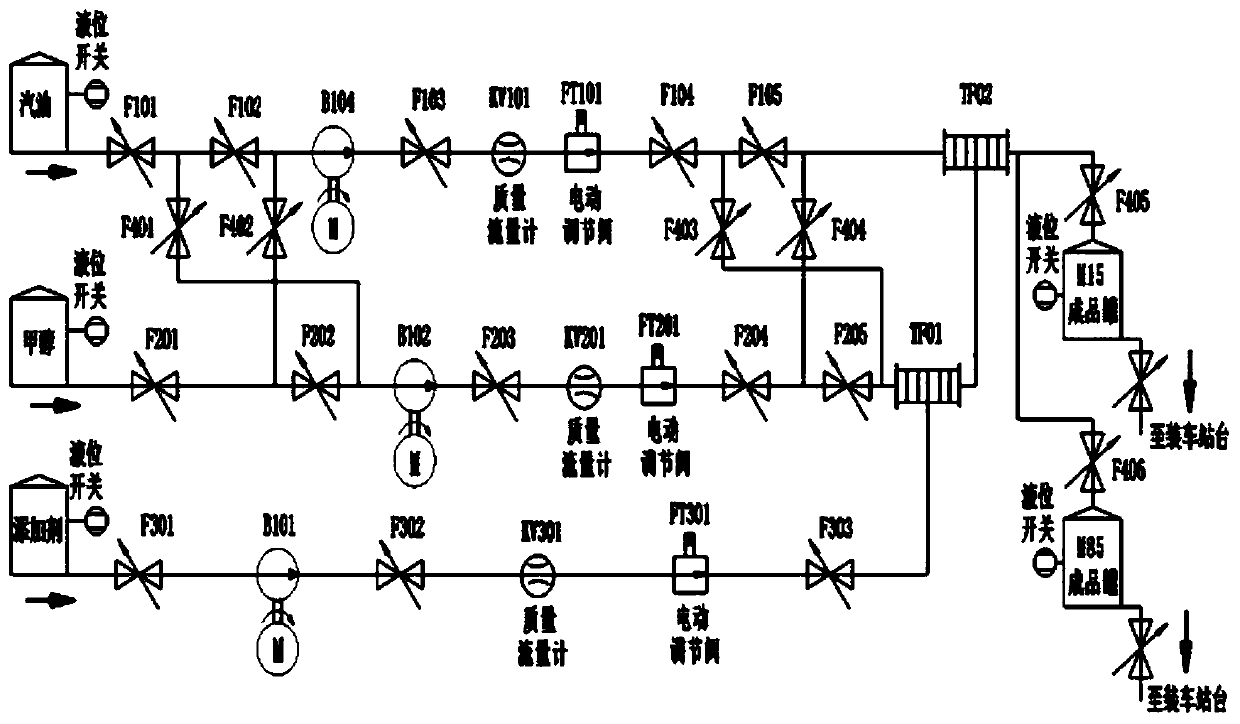

Method used

Image

Examples

preparation example Construction

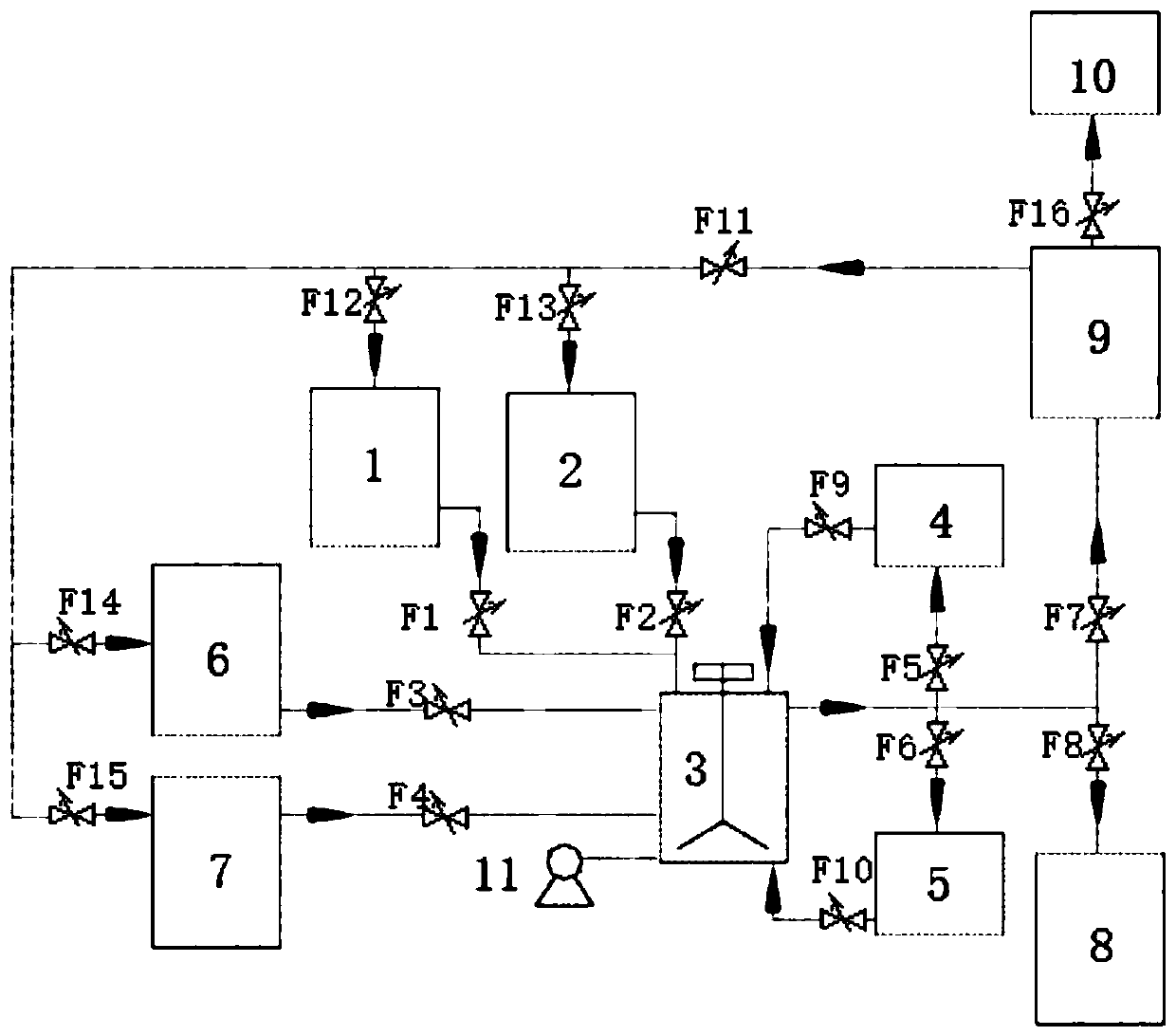

[0035]A kind of preparation method that is used for the composition of engine low-alcohol gasoline additive, adopts the following steps: the first step prepares modifying agent A: vacuumize stirring tank 3, and heat radiation or microwave to stirring tank to 30-35 After ℃, add glycerol (such as the first additive storage tank 1) and ethylene glycol monomethyl ether (the second additive storage tank 2) to the stirring tank 3) through the additive storage tank in turn, so that the ethylene glycol monomethyl ether is added to the glycerin Mixing, centrifugal stirring 8-20min obtains modifier A, modifier A is transferred to modifier A in storage tank 4 and is down to room temperature standby, wherein the revolution number of centrifugal stirring is 1500r / min, ethylene glycol mono The mass ratio of methyl ether and glycerin is 1:6.

[0036] The second step prepares modifier B: the stirring tank 3 is evacuated, and after the stirring tank is heated to 30-35°C by thermal radiation or...

Embodiment 1

[0041] The mass percent of the composition that is used for engine low-alcohol gasoline additive consists of: 3% ethylene glycol monomethyl ether, 18% glycerin, 6% bis-dimethylaminoethyl ether, 30% n-decyl alcohol, 3% nano titanium dioxide , 40% acetone. The mass ratio of the additive composition to methanol gasoline is 9%, such as taking 3.15kg of the additive composition and 35kg of methanol gasoline, and the methanol gasoline (methanol 93# gasoline) is M3.

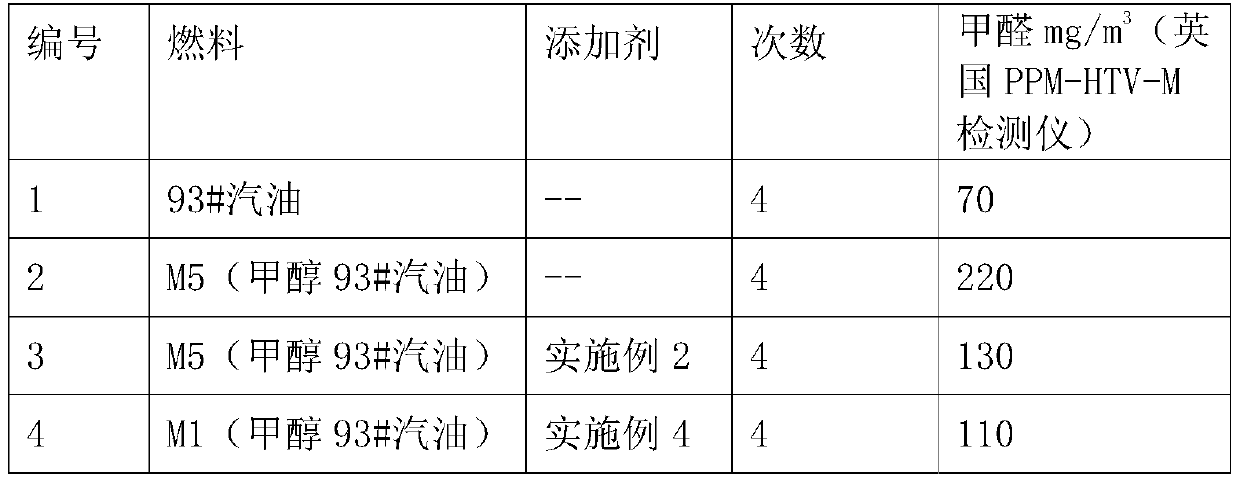

Embodiment 2

[0043] The mass percent of the composition that is used for engine low-alcohol gasoline additive consists of: 3% ethylene glycol monomethyl ether, 18% glycerin, 5% bis-dimethylaminoethyl ether, 40% n-decyl alcohol, 3% nano titanium dioxide , 31% acetone. The mass ratio of the additive composition to methanol gasoline is 12%, such as taking 4.2kg of additive composition and 35kg of methanol gasoline, and the methanol gasoline (methanol 93# gasoline) is M5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com