Comprehensive utilization system and method of low rank coal

A low-rank coal and pulverized coal technology, which is applied in the field of comprehensive utilization system of low-rank coal, can solve the problems of low pulverized coal pelletization rate, low pellet strength, and more hemispheres, so as to improve pelletization rate and reduce gas explosion Phenomenon, the effect of reducing ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

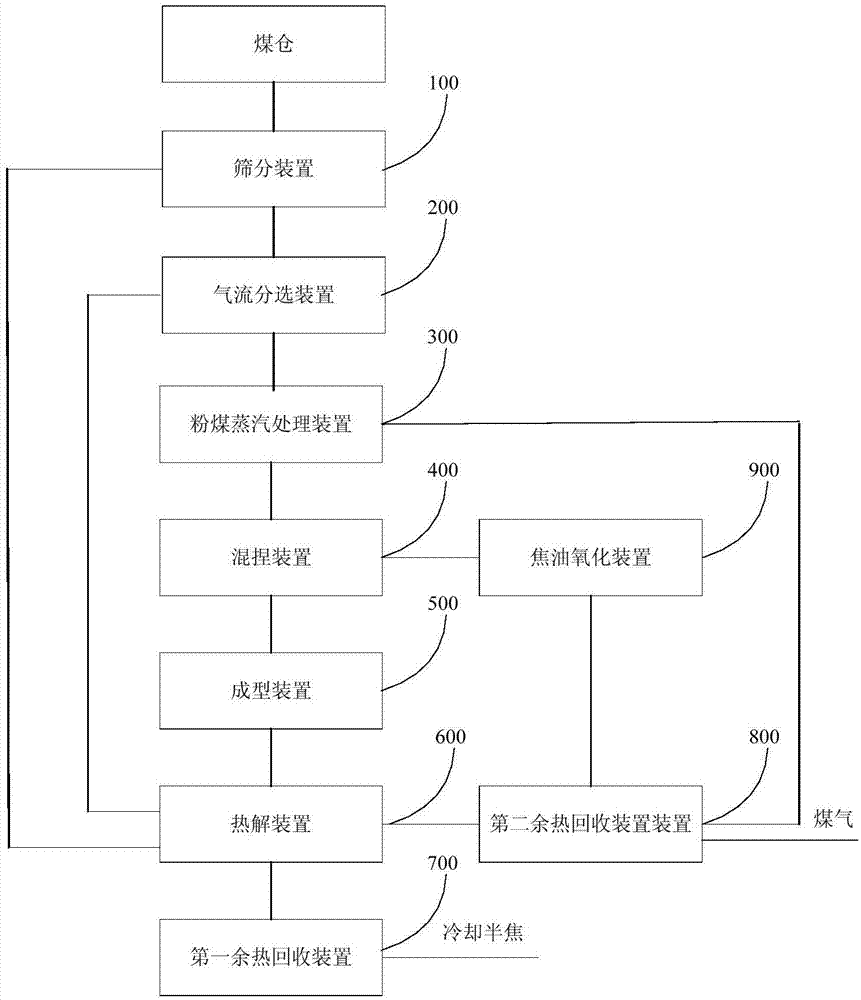

[0057] Firstly, the raw coal is sent from the coal bunker to the screening device 100 through the bucket elevator. The aperture of the screening device is 5mm, and the above-screen lump coal and the under-screen pulverized coal are obtained. The obtained lump coal on the sieve is transported to the rotary bed pyrolysis device 600 through a belt for pyrolysis. The pyrolysis temperature is 600°C and the pyrolysis time is 2.5 hours to obtain pyrolysis semi-coke and pyrolysis gas. High temperature flue gas is discharged from the flue. The pyrolysis gas is sent to the second waste heat recovery device 800 to obtain tar, coal gas and second steam. The obtained tar is oxidized in the tar oxidation device 900, the oxidation temperature is 250° C., the oxidation time is 3 hours, and the air flow rate is 0.5 L / h to obtain a binder for pulverized coal molding. The obtained under-screen pulverized coal is transported to the airflow separation device 200 through a belt, and the high-tempe...

Embodiment 2

[0061] Firstly, the raw coal is sent from the coal bunker to the screening device 100 through the bucket elevator. The aperture of the screening device is 5mm, and the above-screen lump coal and the under-screen pulverized coal are obtained. The obtained lump coal on the sieve is conveyed to the rotary bed pyrolysis device 600 through a belt for pyrolysis. The pyrolysis temperature is 700°C and the pyrolysis time is 1h to obtain pyrolysis semi-coke and pyrolysis gas. At the same time, from the pyrolysis device High temperature flue gas is discharged from the flue. The pyrolysis gas is sent to the second waste heat recovery device 800 to obtain tar, coal gas and second steam. The obtained tar is oxidized in the tar oxidation device 900, the oxidation temperature is 270° C., the oxidation time is 2 hours, and the air flow rate is 5 L / h to obtain a binder for pulverized coal molding. The obtained under-screen pulverized coal is transported to the airflow separation device 200 th...

Embodiment 3

[0065] Firstly, the raw coal is sent from the coal bunker to the screening device 100 through the bucket elevator. The aperture of the screening device is 5mm, and the above-screen lump coal and the under-screen pulverized coal are obtained. The obtained lump coal on the sieve is transported to the rotary bed pyrolysis device 600 through a belt for pyrolysis. The pyrolysis temperature is 900°C and the pyrolysis time is 1.5h to obtain pyrolysis semi-coke and pyrolysis gas. High temperature flue gas is discharged from the flue. The pyrolysis gas is sent to the second waste heat recovery device 800 to obtain tar, coal gas and second steam. The obtained tar is oxidized in the tar oxidation device 900, the oxidation temperature is 350° C., the oxidation time is 1 h, and the air flow rate is 10 L / h to obtain a binder for pulverized coal molding. The obtained pulverized coal under the sieve is transported to the airflow separation device 200 through a belt, and the high-temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com