Aluminum-based self-heating agent self-heating device at extreme low temperature and its application

A self-heating, exothermic agent technology, applied in heating devices, heat exchange materials, chemical instruments and methods, etc., can solve problems such as difficult start, slow heat release, and inability to start exothermic agents, and achieve the effect of avoiding explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A self-heating device for an aluminum-based self-heating agent at extremely low temperatures, including antifreeze lye, a low-temperature heating agent, and an aluminum-based heating agent;

[0045] In this embodiment, the antifreeze lye is 5 mL in total, containing the following solutes in mass percent: 15% sodium chloride, 5% magnesium chloride, and 10% sodium hydroxide.

[0046] The low-temperature heating agent is 5 g in total, containing the following components in mass proportion: 50% of aluminum powder, 10% of iron powder, 10% of magnesium powder, 10% of carbon powder, 10% of calcium oxide and 10% of sodium carbonate, the particle diameter of aluminum powder 200-300μm.

[0047] The aluminum-based heating agent is 40g in total, and the mass ratio of each component is: 40% of aluminum powder, 30% of quicklime, 20% of sodium carbonate, and 10% of zeolite, wherein the particle size of the aluminum powder is between 300-600 μm.

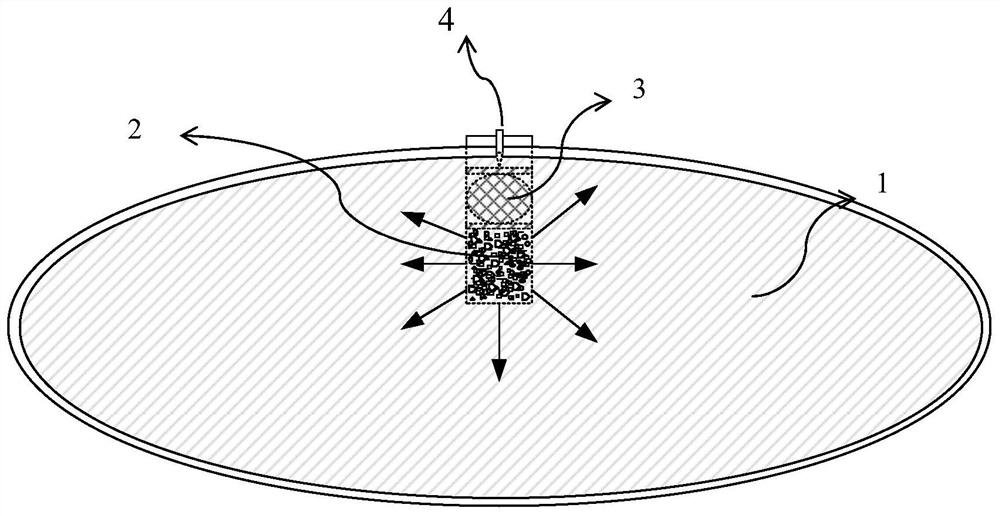

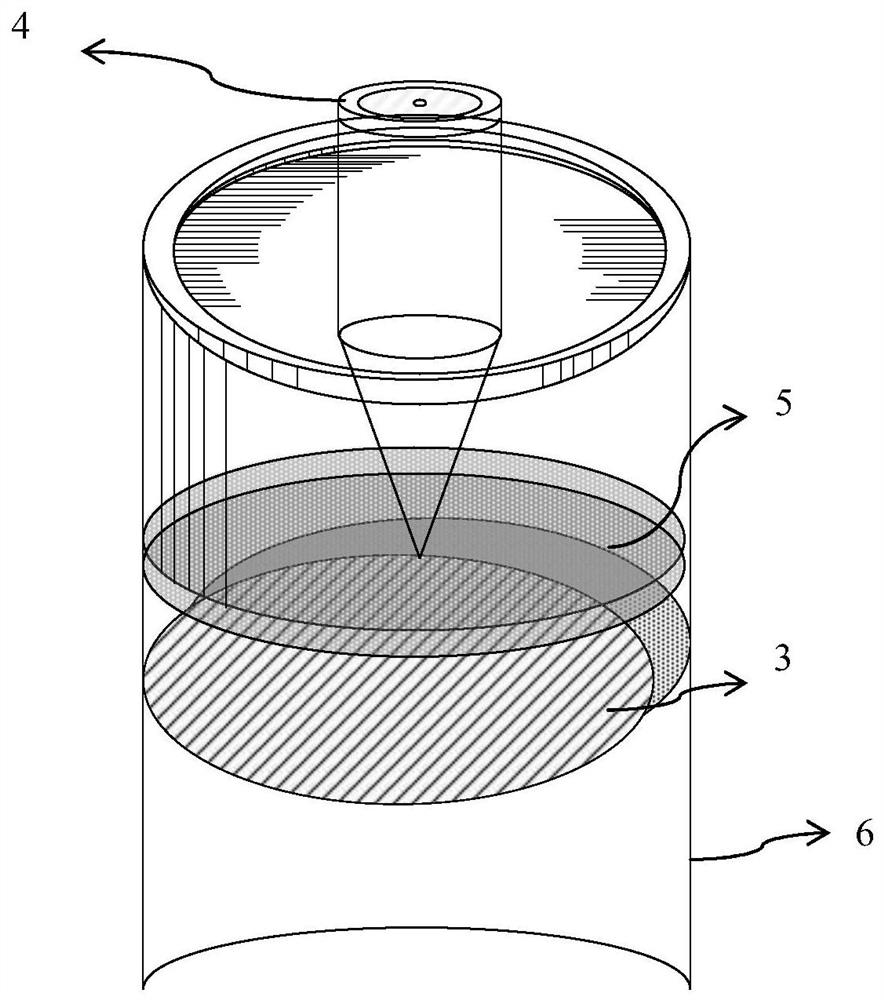

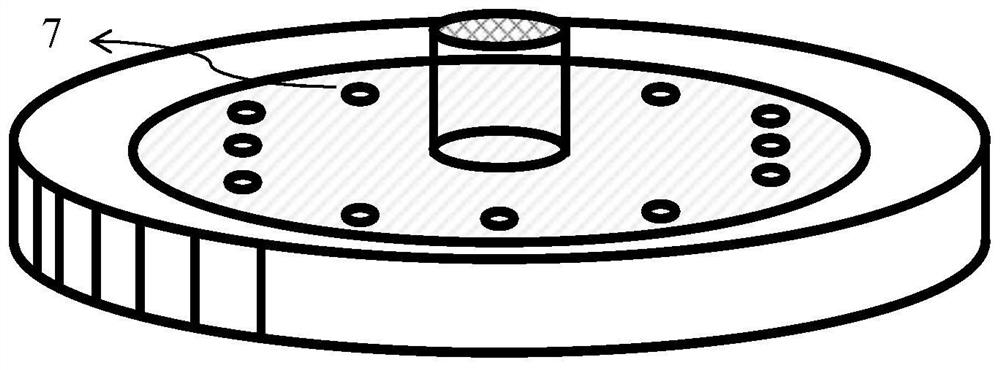

[0048] see figure 1 with figure 2 ...

Embodiment 2

[0055] A self-heating device for an aluminum-based self-heating agent at extremely low temperatures, including antifreeze lye, a low-temperature heating agent, and an aluminum-based heating agent;

[0056] In this embodiment, the antifreeze lye is 5 mL in total, containing the following solutes in mass percent: 10% sodium chloride, 5% magnesium chloride, and 5% potassium hydroxide.

[0057] The low-temperature heating agent is 5g in total, and contains the following components in mass proportion: 50% of aluminum powder, 10% of iron powder, 5% of magnesium powder, 5% of carbon powder, and 30% of calcium oxide. The particle size of the aluminum powder is 200-300 μm.

[0058] The aluminum-based heating agent is 40g in total, and its ingredients are: 40% of aluminum powder, 20% of quicklime, 10% of sodium carbonate, and 10% of zeolite, wherein the particle size of the aluminum powder is between 300-600 μm.

[0059] The structure of this device is basically the same as that of Emb...

Embodiment 3

[0061] A self-heating device for an aluminum-based self-heating agent at extremely low temperatures, including antifreeze lye, a low-temperature heating agent, and an aluminum-based heating agent;

[0062] In this embodiment, the antifreeze lye is 5 mL in total, containing the following solutes in mass percent: 10% sodium chloride, 5% magnesium chloride, and 10% sodium hydroxide.

[0063] The low-temperature heating agent is 5 g in total, and contains the following components in mass proportion: 50% of aluminum powder, 10% of iron powder, 5% of magnesium powder, 15% of carbon powder, and 20% of calcium oxide. The particle size of the aluminum powder is 200-300 μm.

[0064] The aluminum-based heating agent is 40g in total, and its ingredients are: 40% of aluminum powder, 30% of quicklime, 20% of sodium carbonate, and 10% of zeolite, wherein the particle size of the aluminum powder is between 300-600 μm.

[0065] The structure of this device is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com