Preparation process of high-purity phosphorus pentoxide

A phosphorus pentoxide and preparation technology, applied in the direction of phosphorus oxide, phosphorus compound, inorganic chemistry, etc., can solve the problems of raw material yellow phosphorus loss, sewage treatment, difficult to handle, etc., to achieve improved recovery rate and low cost , good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

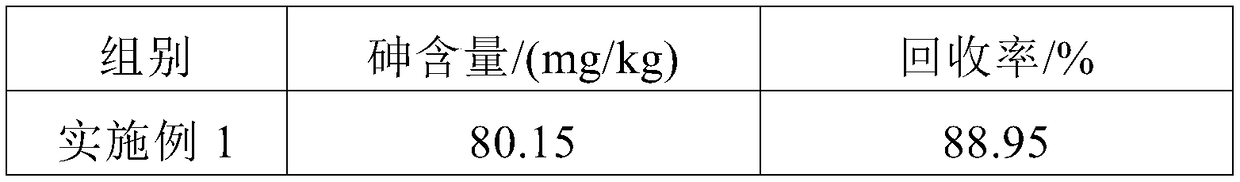

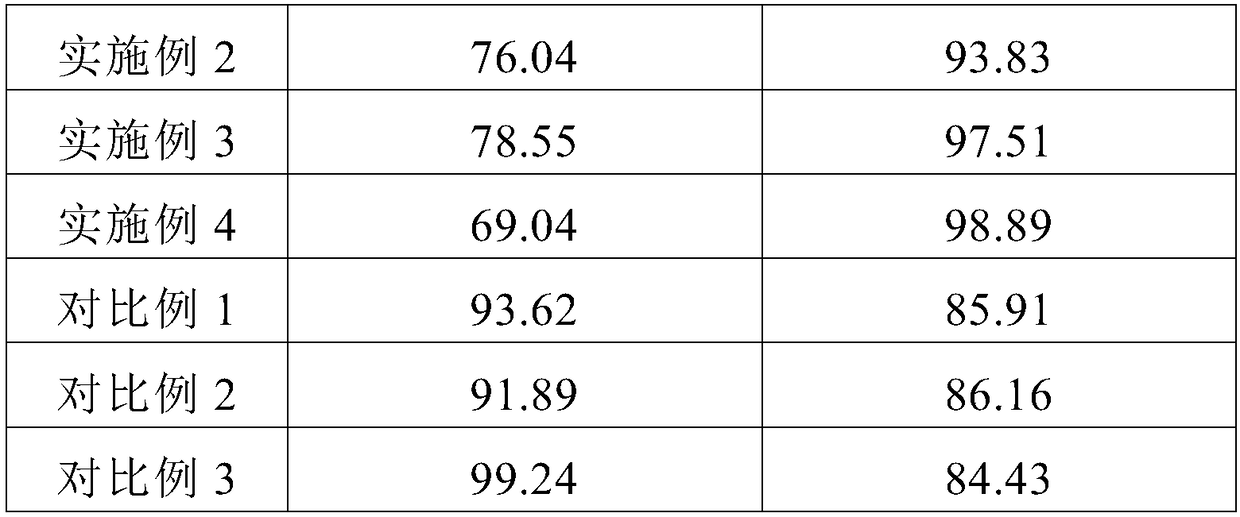

Examples

Embodiment 1

[0036] A preparation process for high-purity phosphorus pentoxide, comprising the steps of:

[0037] Ⅰ. Pretreatment of phosphorus sludge: Mix phosphorus sludge and deionized water at a mass ratio of 1:3, stir for 3 hours at 65°C and 1000r / min, then add 1mol / L hydrochloric acid solution to adjust the pH value to 4 , obtain the pretreated phosphorus sludge solution;

[0038] Ⅱ. Purification and removal of impurities: at 45°C and a working pressure of 0.207 MPa, use a 0.45 μm filter membrane to filter the treated phosphorus mud solution to obtain a filtrate; add 3% hydrogen peroxide to the filtrate mass , stirred at 50°C and 1000r / min for 25min, then added sodium hypochlorite with a solution mass of 5%, kept the temperature and rotational speed constant, continued to stir for 2h, then added nitrilotrimethylene phosphoric acid, diethylenetriamino Pentamethyl phosphoric acid, hexamethylene diamine tetramethylene phosphonic acid, the mass ratio of the solution, nitrilo trimethylen...

Embodiment 2

[0043] A preparation process for high-purity phosphorus pentoxide, comprising the steps of:

[0044] Ⅰ. Pretreatment of phosphorus sludge: Mix phosphorus sludge and deionized water at a mass ratio of 1:3, stir for 3 hours at 65°C and 1000r / min, then add 1mol / L hydrochloric acid solution to adjust the pH value to 4 , obtain the phosphorus mud solution after pH adjustment, then carry out ultrasonic treatment to the phosphorus mud solution after pH adjustment, the ultrasonic power of described ultrasonic treatment is 400W, ultrasonic frequency is 28kHz, and temperature is 50 ℃, and processing time 5h, then at 50 ℃ for 2 hours to obtain the pretreated phosphorus mud solution;

[0045] Ⅱ. Purification and removal of impurities: at 45°C and a working pressure of 0.207 MPa, use a 0.45 μm filter membrane to filter the treated phosphorus mud solution to obtain a filtrate; add 3% hydrogen peroxide to the filtrate mass , stirred at 50°C and 1000r / min for 25min, then added sodium hypochl...

Embodiment 3

[0050] A preparation process for high-purity phosphorus pentoxide, comprising the steps of:

[0051] Ⅰ. Phosphorus sludge pretreatment: Mix phosphorus sludge and deionized water at a mass ratio of 1:3, stir for 3 hours at 65°C and 1000r / min, then freeze at minus 20°C for 20h, and then Stand still at 25°C for 12 hours, add 1mol / L hydrochloric acid solution, adjust the pH value to 4, obtain the phosphorus mud solution after adjusting the pH, then carry out ultrasonic treatment to the phosphorus mud solution after adjusting the pH, the ultrasonic power of the ultrasonic treatment The ultrasonic frequency is 400W, the ultrasonic frequency is 28kHz, the temperature is 50°C, the treatment time is 5h, and then kept at 50°C for 2h to obtain the pretreated phosphorus mud solution;

[0052] Ⅱ. Purification and removal of impurities: at 45°C and a working pressure of 0.207 MPa, use a 0.45 μm filter membrane to filter the treated phosphorus mud solution to obtain a filtrate; add 3% hydrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com