Transparent multifactor degradation modified polyethylene film and preparation method thereof

A polyethylene film and multi-factor technology, applied in the field of transparent multi-factor degradable modified polyethylene film and its preparation, can solve the problems of poor mechanical properties, high cost, limited large-scale use, etc., and achieve the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

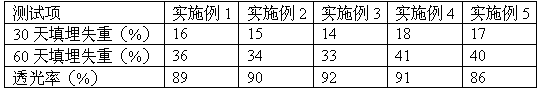

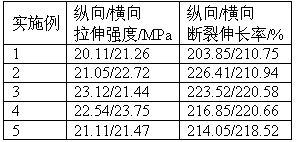

Examples

Embodiment 1

[0021] Example 1 Preparation of transparent multi-factor degradable modified polyethylene film

[0022] (1) Preparation of sulfonated polyether ether ketone: Dissolve industrial grade polyetheretherketone in concentrated sulfuric acid at 50°C, wherein the mass ratio of polyether ether ketone:concentrated sulfuric acid with a mass concentration of 98% is 1:50, and stir 3h, stand still for 24h, add sodium hydroxide to adjust the pH to 7, filter, wash with water, vacuum-dry at 5kPa at 50°C for 30min to obtain sulfonated polyetheretherketone;

[0023] (2) Preparation of modified polyethylene mixture: mix according to the following raw material components, high-density polyethylene (brand DMDA-8008, Dushanzi Petrochemical): sulfonated polyether ether ketone: zinc phenyl phosphate: maleic anhydride Octene Ethylene Copolymer (POE-g-MAH): Polyvinyl Alcohol-Polymethyl Methacrylate Copolymer: Oleoyl Glutamic Acid: Polyethylene Glycol (PEG 400): Sorbitan: Stearic Acid Manganese: methyl ...

Embodiment 2

[0025] Example 2 Preparation of transparent multi-factor degradable modified polyethylene film

[0026] (1) Preparation of sulfonated polyether ether ketone: Dissolve industrial grade polyetheretherketone in concentrated sulfuric acid at 50°C, wherein the mass ratio of polyether ether ketone:concentrated sulfuric acid with a mass concentration of 98% is 1:60, and stir 5h, stand still for 24h, add sodium hydroxide to adjust the pH to 7, filter, wash with water, vacuum-dry at 20kPa and 70°C for 60min to obtain sulfonated polyetheretherketone;

[0027] (2) Preparation of modified polyethylene compound: mix according to the following raw material components, low-density polyethylene (grade 2420D, blue): sulfonated polyetheretherketone: zinc phenylphosphate: maleic anhydride grafted octene Ethylene Copolymer (POE-g-MAH): Polyvinyl Alcohol-Polymethyl Methacrylate Copolymer: Lauroyl Glutamic Acid: Polyethylene Glycol (PEG 400): Sorbitan: Manganese Stearate: Formaldehyde Vinyl ether ...

Embodiment 3

[0029] Embodiment 3 Preparation of transparent multi-factor degradation modified polyethylene film

[0030] (1) Preparation of sulfonated polyether ether ketone: Dissolve industrial grade polyetheretherketone in concentrated sulfuric acid at 50°C, wherein the mass ratio of polyether ether ketone:concentrated sulfuric acid with a mass concentration of 98% is 1:70, and stir 4h, stand still for 24h, add sodium hydroxide to adjust the pH to 7, filter, wash with water, vacuum-dry at 10kPa, 55°C for 35min to obtain sulfonated polyetheretherketone;

[0031] (2) Preparation of modified polyethylene compound: mix according to the following raw material components, linear low density polyethylene (brand 1801, Yangzi Petrochemical): sulfonated polyether ether ketone: zinc phenyl phosphate: maleic anhydride grafted octyl Polyethylene Ethylene Copolymer (POE-g-MAH): Polyvinyl Alcohol-Polymethyl Methacrylate Copolymer: Oleoyl Glutamic Acid: Polyethylene Glycol (PEG 400): Sorbitan: Manganese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com