Heat transfer enhancing anti-corrosion coating material and preparation method thereof

A technology to enhance heat exchange and anti-corrosion coating, applied in anti-corrosion coatings, coatings, polyester coatings, etc., can solve the problems of high construction cost and short anti-corrosion life, achieve good adhesion, anti-corrosion performance, good adhesion Ability, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

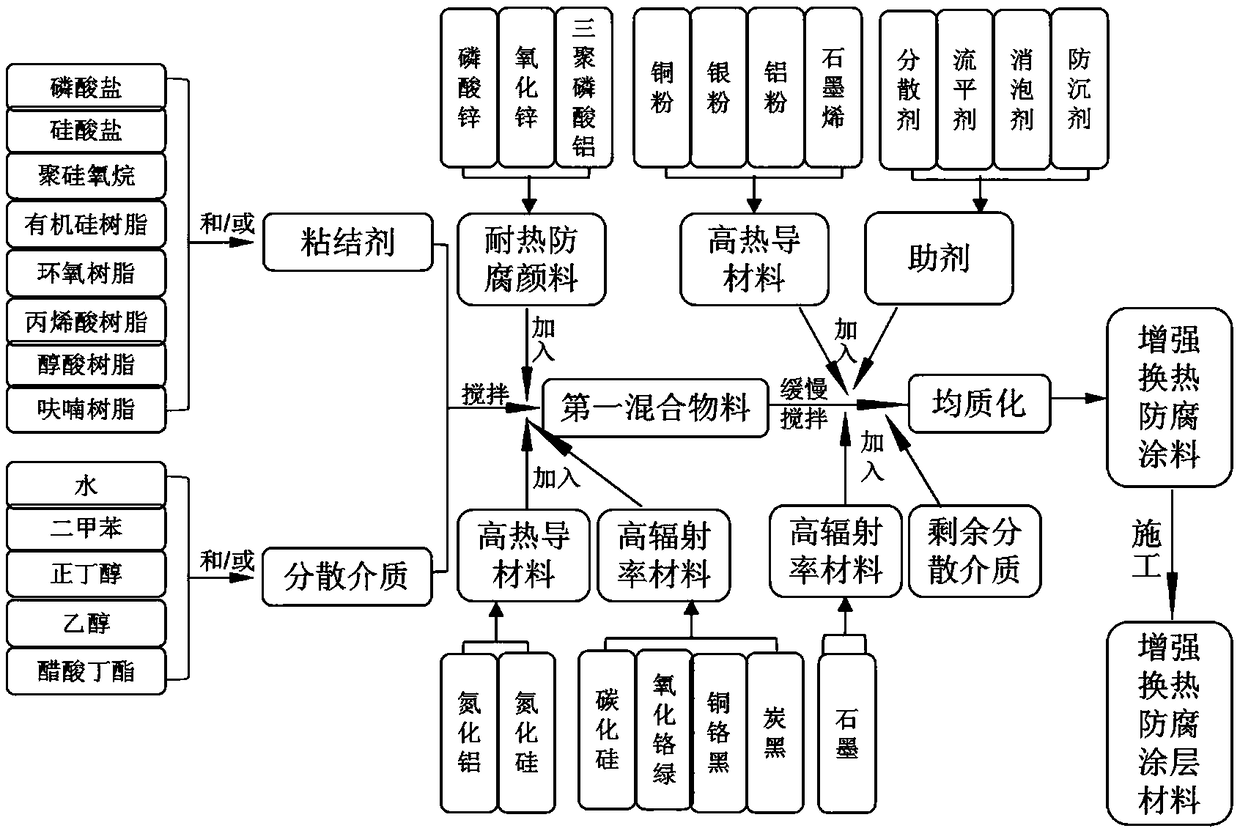

Method used

Image

Examples

Embodiment 1

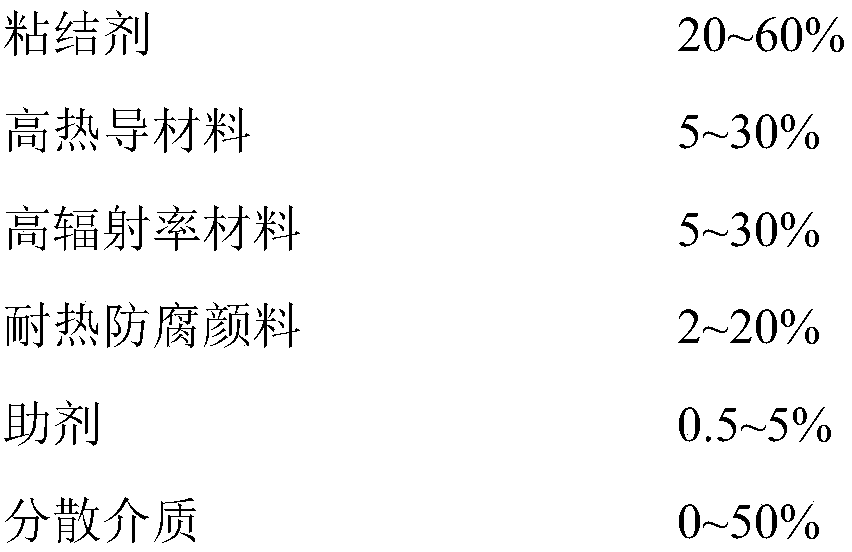

[0045] Raw material ratio: binder aluminum dihydrogen phosphate, magnesium dihydrogen phosphate, zinc dihydrogen phosphate each 10.0g, high thermal conductivity material copper powder 5.0g, high emissivity material silicon carbide 30.0g, heat-resistant anti-corrosion pigment zinc phosphate 15.0g , additive 0.5g, dispersion medium water 19.5g.

[0046] Preparation steps:

[0047] 1. Add the binder aluminum dihydrogen phosphate, magnesium dihydrogen phosphate, zinc dihydrogen phosphate, high-emissivity material silicon carbide, heat-resistant and anti-corrosion pigment zinc phosphate, and some additives to part of the dispersion medium water in proportion, at a linear speed Stir at 1m / s for 1h to obtain the first mixed material;

[0048] 2. Add high thermal conductivity material copper powder to the first mixed material in proportion, then add the remaining dispersion medium water and some additives, stir at a line speed of 1m / s for 30min, use a temperature-controllable high-pr...

Embodiment 2

[0058] Raw material ratio: binder sodium silicate 50.0g, high thermal conductivity material aluminum powder 15.0g, high emissivity material chromium oxide green 15.0g, heat-resistant and anti-corrosion pigment zinc phosphate 15.0g, additive 1.0g, dispersion medium water 4.0g .

[0059] Preparation steps:

[0060] 1. Add the binder sodium silicate, high-emissivity material chromium oxide green, heat-resistant and anti-corrosion pigment zinc phosphate, and some additives in proportion to part of the dispersion medium water, and stir for 1 hour at a line speed of 1m / s to obtain the first mixture material;

[0061] 2. Add high thermal conductivity material aluminum powder to the first mixed material in proportion, then add the remaining dispersion medium water and some additives, stir at a linear speed of 4m / s for 30min, use a temperature-controllable high-pressure homogeneous disperser at a temperature of 10 ℃, pressure 150MPa to completely homogenize the coating, and filter th...

Embodiment 3

[0071] Raw material ratio: binder polysiloxane resin 60.0g, high thermal conductivity material silver powder 5.0g, high emissivity material copper chrome black 20.0g, heat-resistant and anti-corrosion pigment aluminum tripolyphosphate 8.0g, additive 3.0g, dispersion medium Butanol 3.0g, ethanol 1.0g.

[0072] Preparation steps:

[0073] 1. Add the binder polysiloxane resin, high emissivity material copper chrome black, heat-resistant and anti-corrosion pigment aluminum tripolyphosphate, and some additives to part of the dispersion medium butanol and ethanol in proportion, at a linear speed of 2m / s Stir for 30min to obtain the first mixed material;

[0074] 2. Add high thermal conductivity material silver powder to the first mixed material in proportion, then add the remaining dispersion medium butanol, ethanol and some additives, stir at a linear speed of 4m / s for 30min, use a temperature-controllable high-pressure homogeneous disperser to The temperature is 4°C and the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com