A kind of preparation method of pedot:pss base flexible ammonia gas sensor

A kind of ammonia sensor, based flexible technology, applied in the field of preparation of PEDOT:PSS based flexible ammonia sensor, can solve the problems of long test time, unfavorable low cost and wearable devices, unfavorable low cost manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The PEDOT of embodiment 1: the preparation method of PSS base flexible ammonia sensor comprises the following steps:

[0023] (1) prepare a flexible substrate made of polyimide transparent film, adopt ethanol and acetone to carry out ultrasonic cleaning to this flexible substrate successively, ultrasonic cleaning time is 15 minutes, after ultrasonic cleaning, in constant temperature electric blast drying box with Dry at 100°C for 10 minutes and set aside;

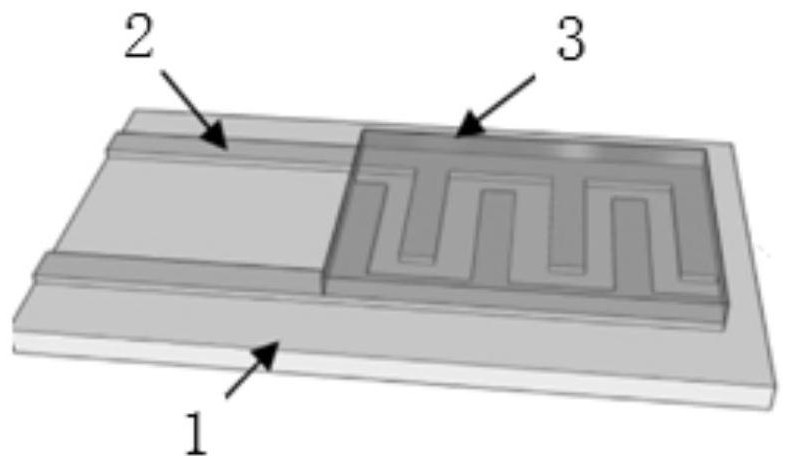

[0024] (2) Use a silk screen stencil to screen-print conductive silver particle ink on the flexible substrate, and then heat-treat it in a constant temperature electric blast drying oven at 100°C for 10 minutes to prepare silver interdigitated electrodes on the flexible substrate;

[0025] (3) Prepare a PEDOT:PSS aqueous solution with a mass concentration of 0.1%, add 0.05% Tween 20 as a surfactant, and ultrasonically vibrate for 30 minutes to prepare a PEDOT:PSS precursor ink;

[0026] (4) Inkjet printing PEDOT:PSS...

Embodiment 2

[0028] The PEDOT of embodiment 2: the preparation method of PSS base flexible ammonia sensor comprises the following steps:

[0029] (1) prepare a flexible substrate made of polyethylene terephthalate transparent film, adopt ethanol and acetone to carry out ultrasonic cleaning to this flexible substrate successively, ultrasonic cleaning time is 20 minutes, after ultrasonic cleaning, in constant temperature electric drum Dry in an air drying oven at 120°C for 20 minutes, and set aside;

[0030] (2) On the flexible substrate, the conductive nano-silver wire ink was printed with an inkjet printer, and then heat-treated at 150°C for 15 minutes in a constant temperature electric blast drying oven to prepare silver interdigitated electrodes on the flexible substrate;

[0031] (3) Prepare a PEDOT:PSS aqueous solution with a mass concentration of 2%, add 0.5% cetyltrimethylammonium bromide as a surfactant, and ultrasonically vibrate for 60 minutes to prepare a PEDOT:PSS precursor ink;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com