Stable organic solar cell and preparation method thereof

A solar cell and organic technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as chemical synthesis problems, device efficiency effects, etc., and achieve the effects of improving light stability, high energy conversion efficiency, and energy conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

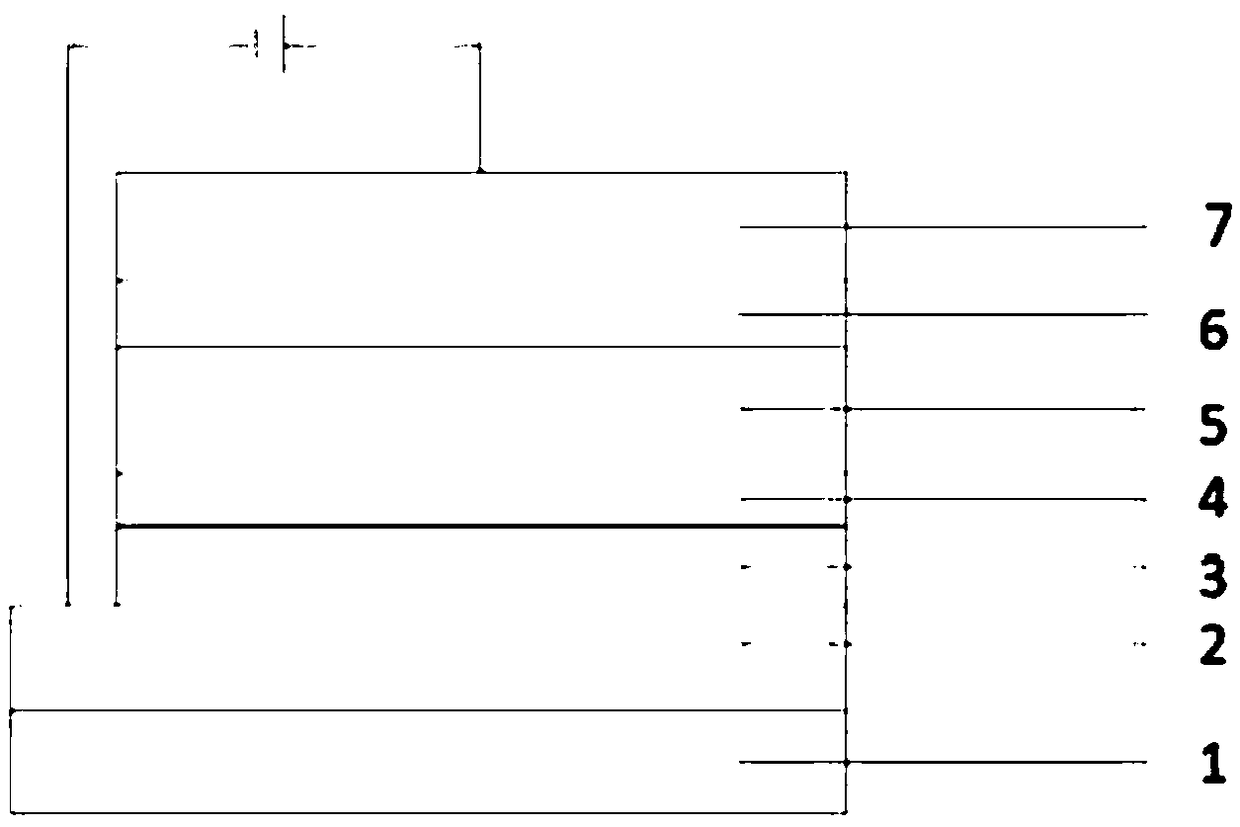

[0033] (1) The glass substrate coated with the ITO layer is ultrasonically cleaned with isopropanol, detergent and deionized water in sequence, and then dried in an oven for subsequent use;

[0034] (2) Dissolve 0.4g of zinc acetate in 4ml of monomethyl ether solution, then add 111 microliters of ethanolamine solution and stir at 50°C for 12h, then spin-coat the prepared ZnO precursor solution on ITO as an electron transport layer , with a rotation speed of 3000rpm and a thickness of 30nm; then thermal annealing at 200°C for 1h;

[0035] (3) put C 60 -SAM solid is dissolved in the mixed solution of chlorobenzene and tetrahydrofuran, the volume ratio of chlorobenzene and tetrahydrofuran in the mixed solution is 1:1 (the amount of chlorobenzene is 2ml), and then the solution is heated at 50°C at a speed of 150 rpm Stir for 12h, filter with a filter head to obtain a clear solution that is C 60 -SAM solution. Will C 60 -SAM solution was spin-coated on the ZnO electron transpor...

Embodiment 2

[0054] (1) The glass substrate coated with the ITO layer is ultrasonically cleaned with isopropanol, detergent and deionized water in sequence, and then dried in an oven for subsequent use;

[0055] (2) Dissolve 0.4g of zinc acetate in 4ml of monomethyl ether solution, then add 111 microliters of ethanolamine solution and stir at 50°C for 12h, then spin-coat the prepared ZnO precursor solution on ITO as an electron transport layer , with a rotation speed of 3000rpm and a thickness of 30nm; then thermal annealing at 200°C for 1h;

[0056] (3) 6mg C 60 -SAM solid is dissolved in the mixed solution of chlorobenzene and tetrahydrofuran, the volume ratio of chlorobenzene and tetrahydrofuran in the mixed solution is 1:1 (the amount of chlorobenzene is 2ml), and then stirred at 50°C for 12h at a rate of 150 rpm , and then filtered through a 0.45 micron filter to obtain a clear solution. Take 35 μl C 60 -SAM solution was spin-coated on the ZnO electron transport layer as a modified...

Embodiment 3

[0073] (1) The glass substrate coated with the ITO layer is ultrasonically cleaned with isopropanol, detergent and deionized water in sequence, and then dried in an oven for subsequent use;

[0074] (2) Dissolve 0.4g of zinc acetate in 4ml of monomethyl ether solution, then add 111 microliters of ethanolamine solution and stir at 50°C for 12h, then spin-coat the prepared ZnO precursor solution on ITO as an electron transport layer , with a rotation speed of 3000rpm and a thickness of 30nm; then thermal annealing at 200°C for 1h;

[0075] (3) 6mg C 60 -SAM solid is dissolved in the mixed solution of chlorobenzene and tetrahydrofuran, the volume ratio of chlorobenzene and tetrahydrofuran in the mixed solution is 1:1 (the amount of chlorobenzene is 2ml), and then stirred at 50°C for 12h at a rate of 150 rpm , and then filtered through a 0.45 micron filter to obtain a clear solution. Take 35 μl C 60 -SAM solution was spin-coated on the ZnO electron transport layer as a modified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com