Novel polycarboxylic acid high-performance nano seed crystal early-strength water reduction complex agent and preparation method thereof

An early-strength water-reducing agent and polycarboxylic acid technology, which is applied in the field of new-type polycarboxylic acid high-performance nano-seed early-strength water-reducing composite agent and its preparation, can solve the adverse effects of concrete workability and durability, and high energy consumption , affect the later strength and other issues, achieve the effect of accelerating the cement hydration process, simplifying the preparation process, and improving the early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

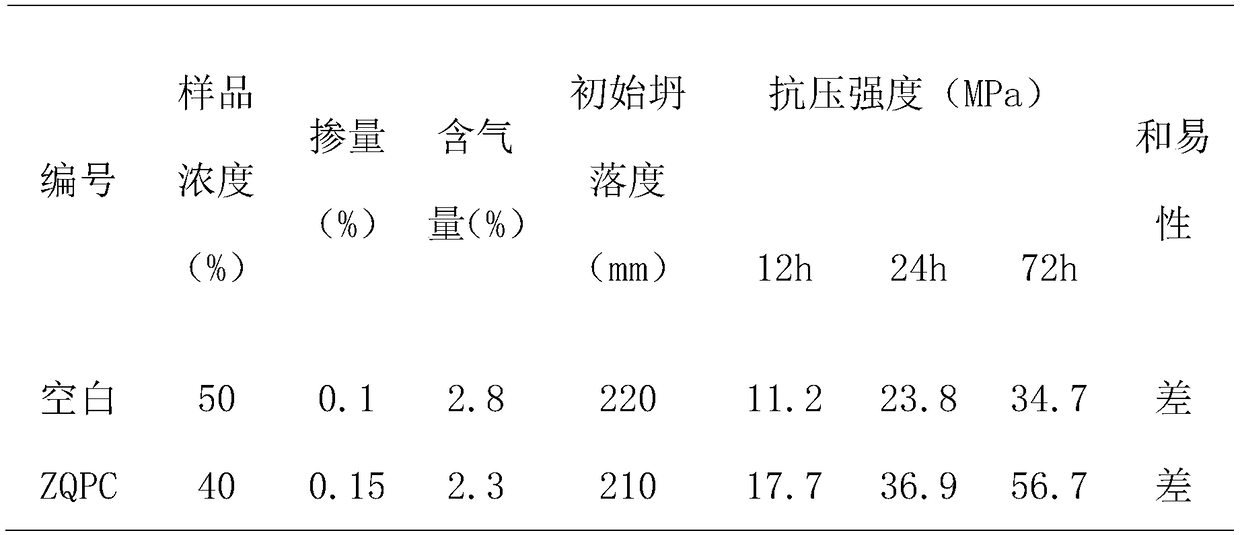

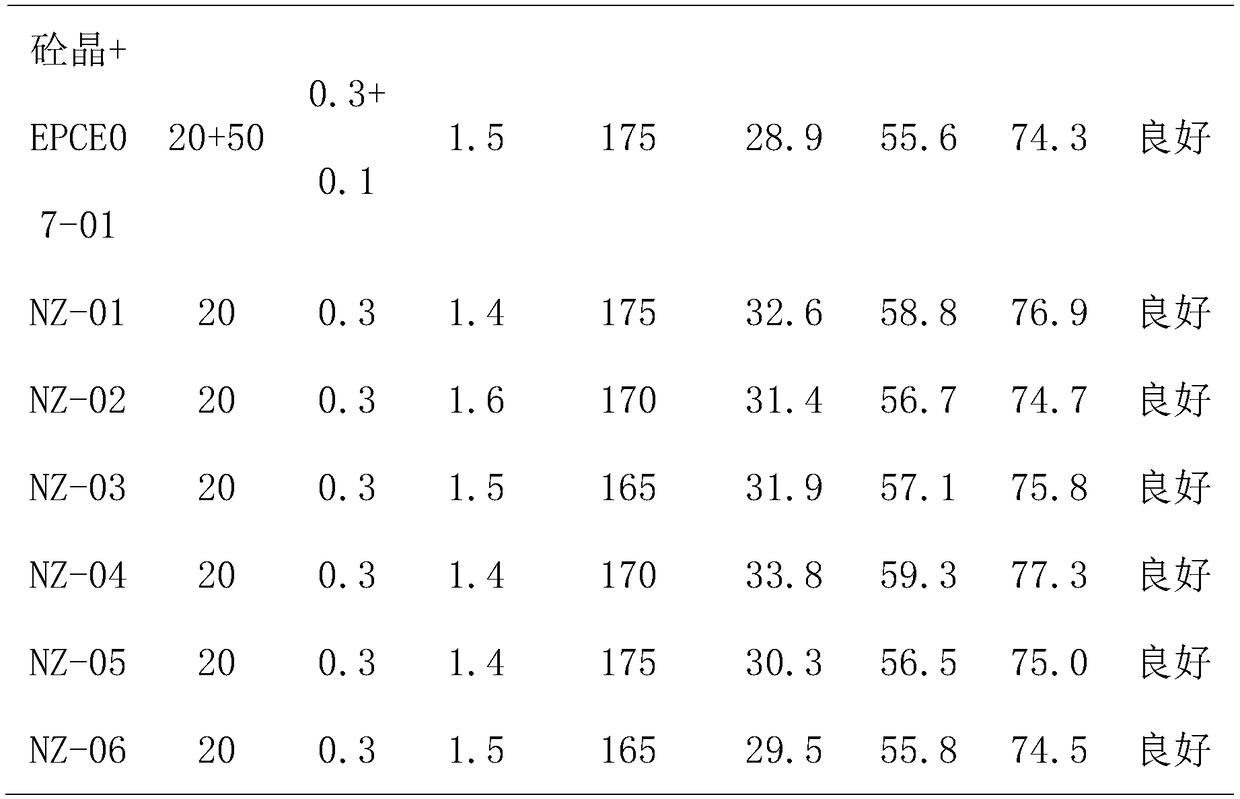

Examples

Embodiment 1

[0020] Step 1: Add 124.77g polycarboxylate early strength superplasticizer (acid ether ratio 4.5), 636g deionized water, 1.2g fatty alcohol polyoxyethylene ether phosphate, 2.5g polyaminopolyether-based methylenephosphonic acid Mix evenly in the round-bottomed flask, then add 7.5g of 30% sodium hydroxide solution to adjust the pH of the solution to 11-12 to obtain mixed solution A;

[0021] Step 2: Add the mixed solution B consisting of 52g calcium nitrate, 14.625g polycarboxylate early-strength water reducing agent, 92.44g ionized water, and 60g sodium silicate, 14.625g polycarboxylate early-strength reducing agent into solution A at the same time. The mixed solution C composed of water agent and 80.13g deionized water was added dropwise for 2.5h, and the reaction was continued for 10min after the dropwise addition was completed;

[0022] Step 3: Add 0.4 g of defoaming agent, and use a high-speed shearing machine for shearing for 5 minutes. The obtained solution in a stable s...

Embodiment 2

[0024] Step 1: 104.4g polycarboxylate early strength superplasticizer (acid-ether ratio is 4), 20.04g silica sol, 653g deionized water, 0.9g sodium dodecylbenzenesulfonate, 3.2g polyaminopolyether group The methylene phosphonic acid was added to the round-bottomed flask and mixed evenly, and then 6.78g of 30% sodium hydroxide solution was added to adjust the pH of the solution to 11-12 to obtain mixed solution A;

[0025] Step 2: Add the mixed solution B consisting of 66g calcium nitrate, 18.56g polycarboxylate early-strength water reducing agent, 117.33g ionized water, and 51g sodium silicate, 18.56g polycarboxylate early-strength reducing agent into solution A at the same time. The mixed solution C composed of water agent and 94.87g deionized water was added dropwise for 2.5h, and the reaction was continued for 10min after the dropwise addition was completed;

[0026] Step 3: Add 0.36 g of defoaming agent, and use a high-speed shearing machine for shearing for 5 minutes, and...

Embodiment 3

[0028] Step 1: 96.73g polycarboxylate early strength water reducing agent (acid ether ratio is 4), 18.8g Al 2 O 3 Sol, 648g of deionized water, 1.2g of fatty alcohol polyoxyethylene ether sodium sulfate, 2.8g of tetrapolymer TH-241 were added to the round-bottomed flask and mixed well, and then 6.36g of 30% sodium hydroxide solution was added to adjust the pH of the solution to 11 -12, to obtain mixed solution A;

[0029] Step 2: Add the mixed solution B composed of 72g calcium nitrate, 20.25g polycarboxylate early strength water reducing agent, 128g ionized water and 87g sodium silicate, 20.25g polycarboxylate early strength water reducing agent into solution A at the same time The mixed solution C composed of 102.83g deionized water and 102.83g deionized water was added dropwise for 2.5h, and the reaction was continued for 10min after the dropwise addition was completed;

[0030] Step 3: Add 0.3 g of defoaming agent, use a high-speed shearing machine for shearing for 5 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com