Narrow band gap sodium bismuth titanate-nickel barium titanate ferroelectric material, and preparation method and application thereof

A ferroelectric material, bismuth sodium titanate technology, applied in the field of ferroelectric materials, can solve the problem of not being able to use the visible and near-infrared parts of the solar spectrum, and achieve the effect of large photoresponse current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

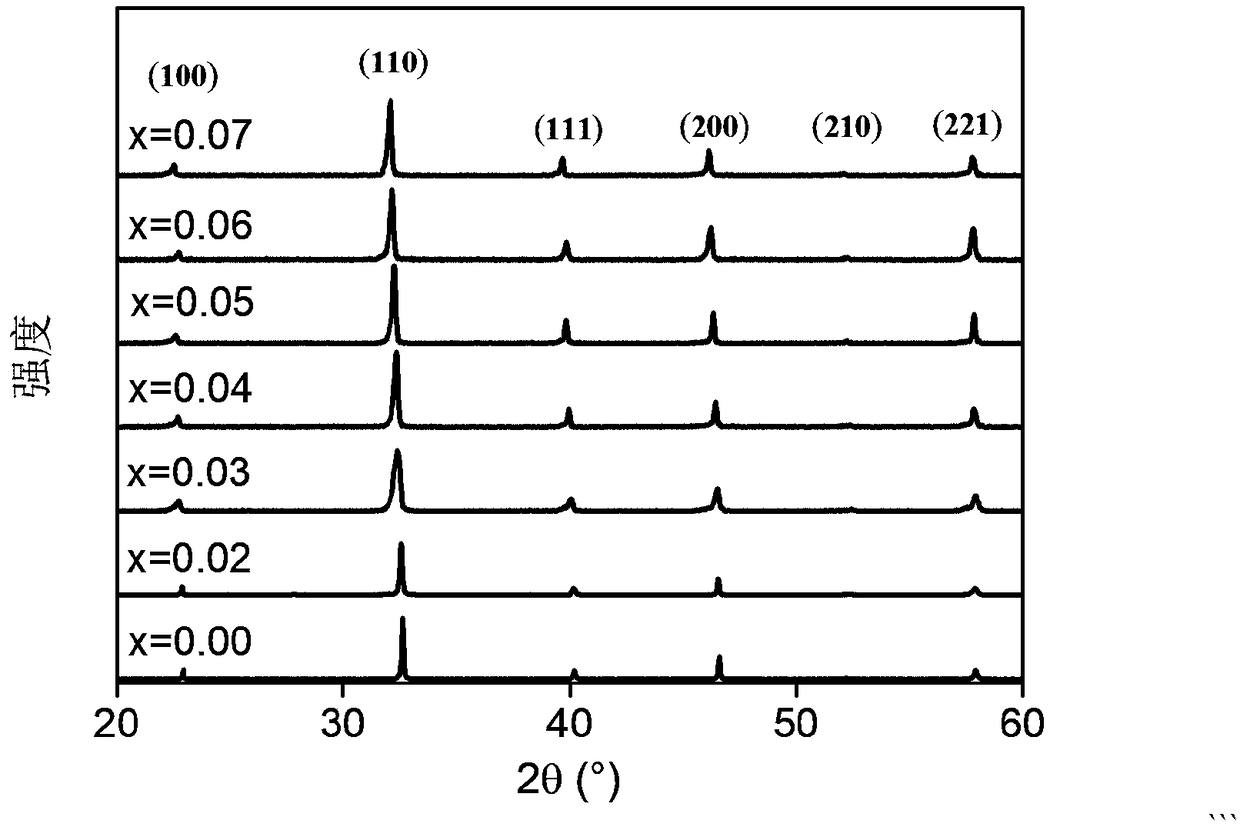

[0039] According to the general formula (1-x)(Na 0.5 Bi 0.5 )TiO 3 -xBa(Ti 0.5 Ni 0.5 )O 2.5 The bismuth sodium titanate-barium nickel titanate, which is a high-voltage ferroelectric material with a narrow band gap, is formulated.

[0040] When x=0.02, its formula is 0.98 (Na 0.5 Bi 0.5 )TiO 3 -0.02Ba(Ti 0.5 Ni 0.5 )O 2.5 .

[0041] The first step: using analytically pure sodium carbonate, barium carbonate, bismuth carbonate, bismuth oxide, titanium dioxide and nickel oxide as raw materials, according to the stoichiometric ratio, calculate the mass of each raw material component required and weigh it to obtain the ingredients ;

[0042] The second step: use absolute ethanol as the ball milling medium for the ingredients, and use a roller ball mill for 48 hours to dry to obtain a mixed dry powder;

[0043] The third step: pre-burn the mixed dry powder obtained in the second step at 850°C for 4 hours, add polyvinyl alcohol aqueous solution to the pre-fired powder to...

Embodiment 2

[0051] When x=0.03, its formula is 0.97 (Na 0.5 Bi 0.5 )TiO 3 -0.03Ba(Ti 0.5 Ni 0.5 )O 2.5

[0052] The preparation method in this example is the same as that in Example 1, except that the amount of barium nickel titanate powder mixed in the preparation process is different. The amount of the mixed substance in this example is 3% barium nickel titanate.

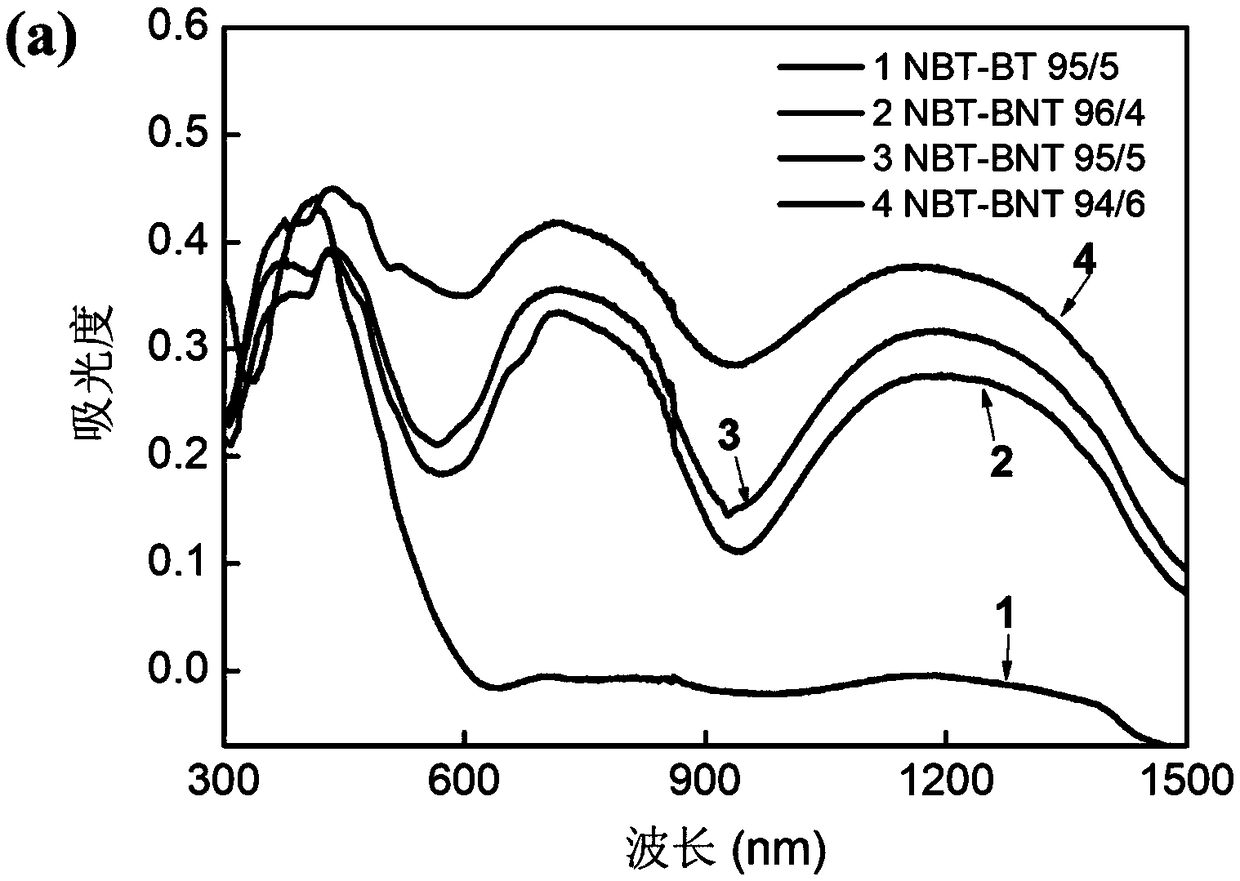

[0053] Material optical bandgap: Eg 1 =0.95eV, Eg 2 =1.42eV, Eg 3 =2.43eV;

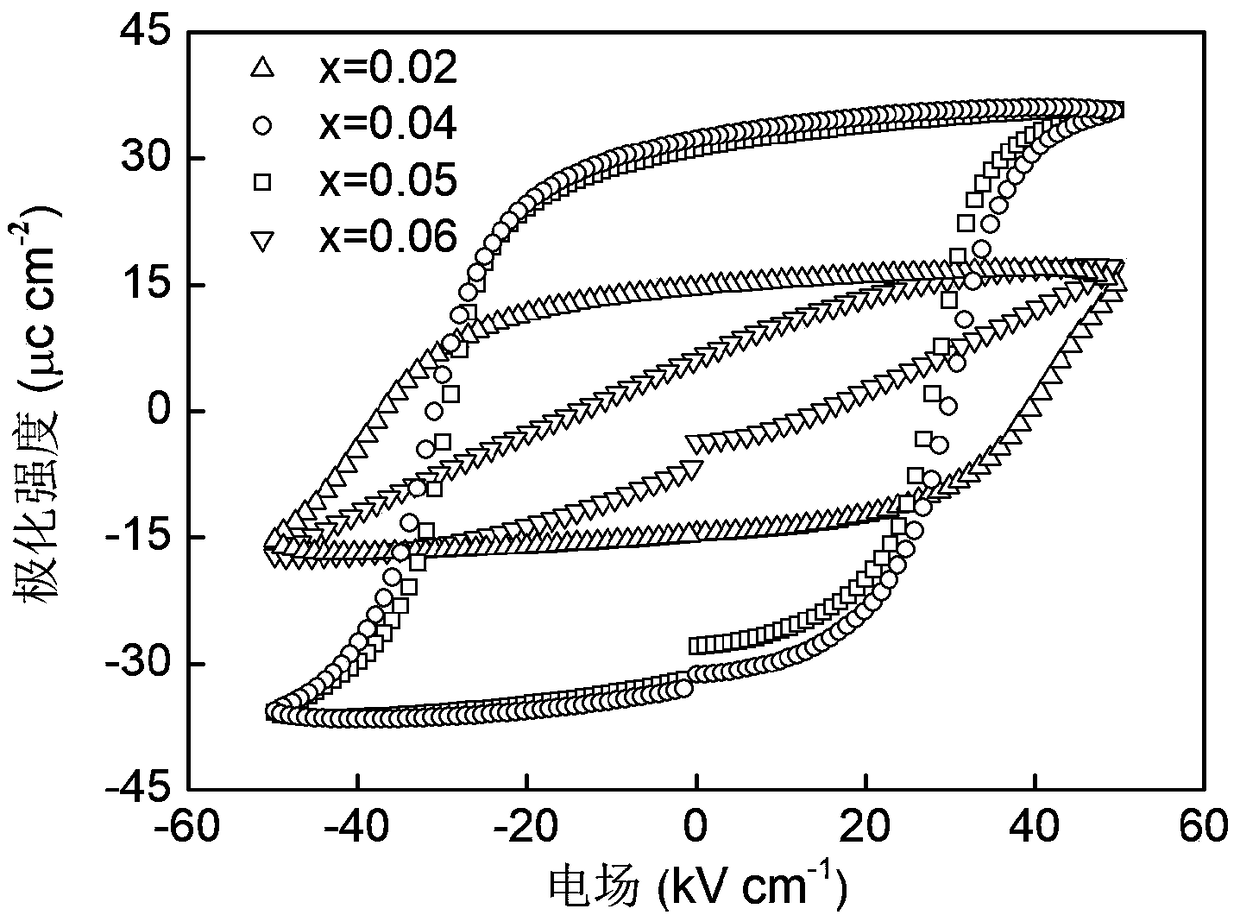

[0054] Material electrical properties: d 33 =113 pC N -1 , P r =25.7μC cm -2 ,T d = 142.35°C.

Embodiment 3

[0056] When x=0.04, its formula is 0.96 (Na 0.5 Bi 0.5 )TiO 3 -0.04Ba(Ti 0.5 Ni 0.5 )O 2.5

[0057] The preparation method in this example is the same as that in Example 1, except that the amount of barium nickel titanate powder mixed in the preparation process is different, and the amount of the mixed substance in this example is 4% barium nickel titanate.

[0058] Material optical bandgap: Eg 1 =0.94eV, Eg 2 =1.41eV, Eg 3 =2.40eV;

[0059] Material electrical properties: d 33 =130pC N -1 , P r =29.6μC cm -2 ,T d = 120.79°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com