In-situ preparation method for magnetic wood-based material

A technology of in-situ preparation of wood-based materials, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve problems such as long time and complicated preparation process, Achieve the effects of low cost, simple process, and high-efficiency catalytic degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

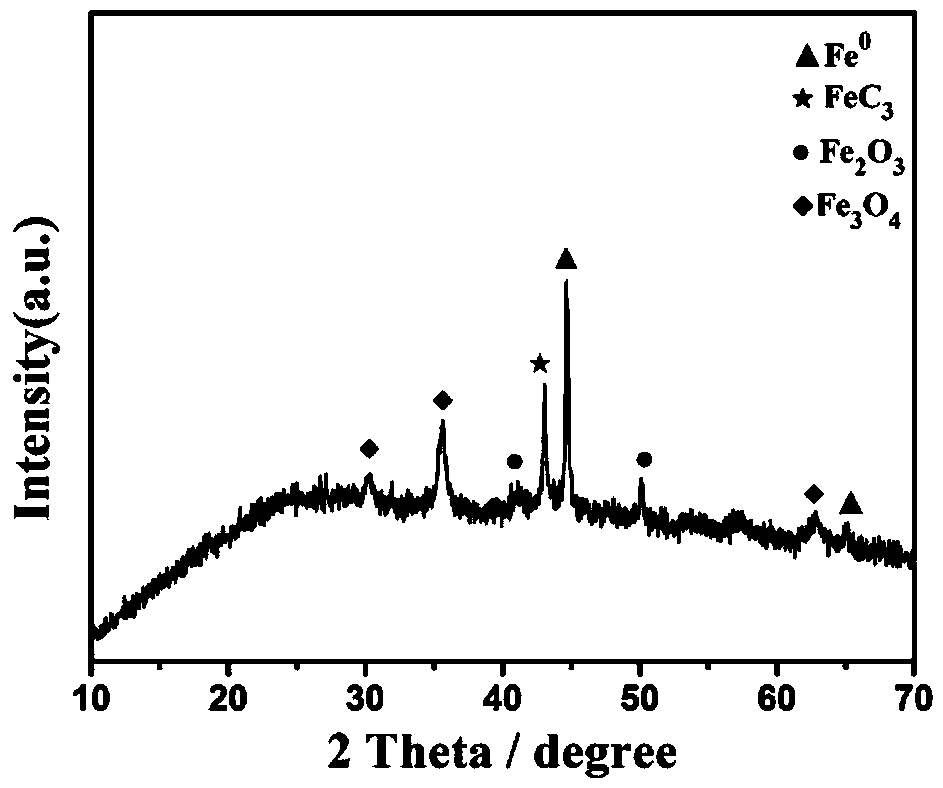

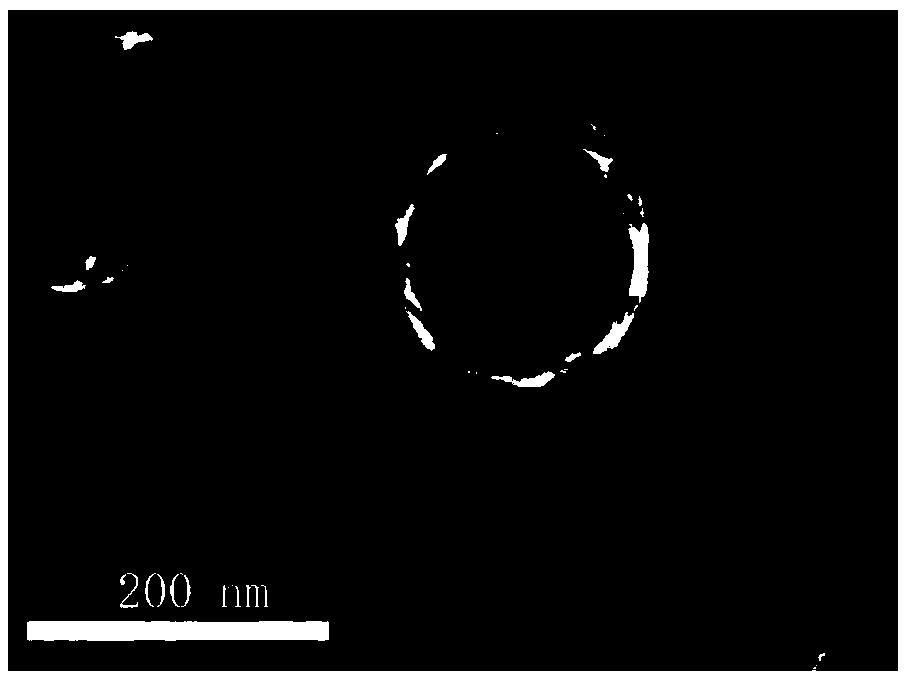

[0036] Soak the balsa wood block in 0.3mol / L ferric nitrate solution, the ratio of the volume (mL) of the iron salt solution to the weight (g) of the block is 75:1; magnetically stir for 2 hours at room temperature, mix the solution with the wood The blocks were transferred together into a stainless steel autoclave, sealed, and placed in a constant temperature drying oven at 200°C for 8 hours. After the reaction, the product is filtered to obtain a magnetic wood-based precursor, which is washed with water and absolute ethanol until the residual iron ion concentration in the precursor is 0.05g / L, and alternately washed with water and absolute ethanol to reach the above standard. Yes, after washing and drying, put the precursor in a tube furnace, feed nitrogen gas, raise the temperature to 900°C at a rate of 10°C / min, and keep at this temperature for 2 hours to obtain a magnetic wood-based material. Its shape is as follows image 3 As shown, it can be seen that the magnetic wood...

Embodiment 2

[0039] Get the basswood block and soak it in 2mol / L ferric chloride solution, the volume (mL) of the iron salt solution and the weight (g) ratio of the block are 85:1, stir magnetically for 5h at room temperature, and mix the solution with the block Transfer them together to a stainless steel autoclave, seal it, and place it in a constant temperature drying oven at 240°C for 10 hours. Filter the reacted product to obtain a magnetic wood-based precursor, wash the precursor with water and absolute ethanol until the residual iron ion concentration in the precursor is 0.1g / L, alternately wash with water and absolute ethanol until the above standard is reached, After washing and drying, the precursor was placed in a tube furnace, fed with nitrogen, and the temperature was raised to 800°C at a rate of 5°C / min, and kept at this temperature for 3 hours to obtain a magnetic wood-based material.

Embodiment 3

[0041] Soak the white pine wood block in 1mol / L ferrous sulfate solution, the ratio of the volume (mL) of the iron salt solution to the weight (g) of the wood block is 100:1, stir magnetically for 4 hours at room temperature, and put the solution and the wood block together Transfer to a stainless steel autoclave, seal it, and place it in a constant temperature drying oven at 180°C for 9 hours. Filter the reacted product to obtain a magnetic wood-based precursor. Wash the precursor with water and absolute ethanol until the residual iron ion concentration in the precursor is 0.04g / L. Wash with water and absolute ethanol alternately until the above standard is reached. After washing and drying, the precursor was placed in a tube furnace, fed with nitrogen, and the temperature was raised to 1000°C at a rate of 8°C / min, and kept at this temperature for 1 hour to obtain a magnetic wood-based material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com