Method for continuously preparing aniline diazonium salt and phenylhydrazine hydrochloride on basis of microreactor

A technology of phenylhydrazine hydrochloride and microreactor, which is applied in chemical instruments and methods, hydrazine preparation, chemical/physical/physical-chemical reactors, etc., can solve the problem of long reaction time of phenylhydrazine hydrochloride, excess reaction raw materials, discontinuous reaction, etc. problems, to achieve the effect of shortening the reaction time, increasing the reaction temperature, and improving the process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

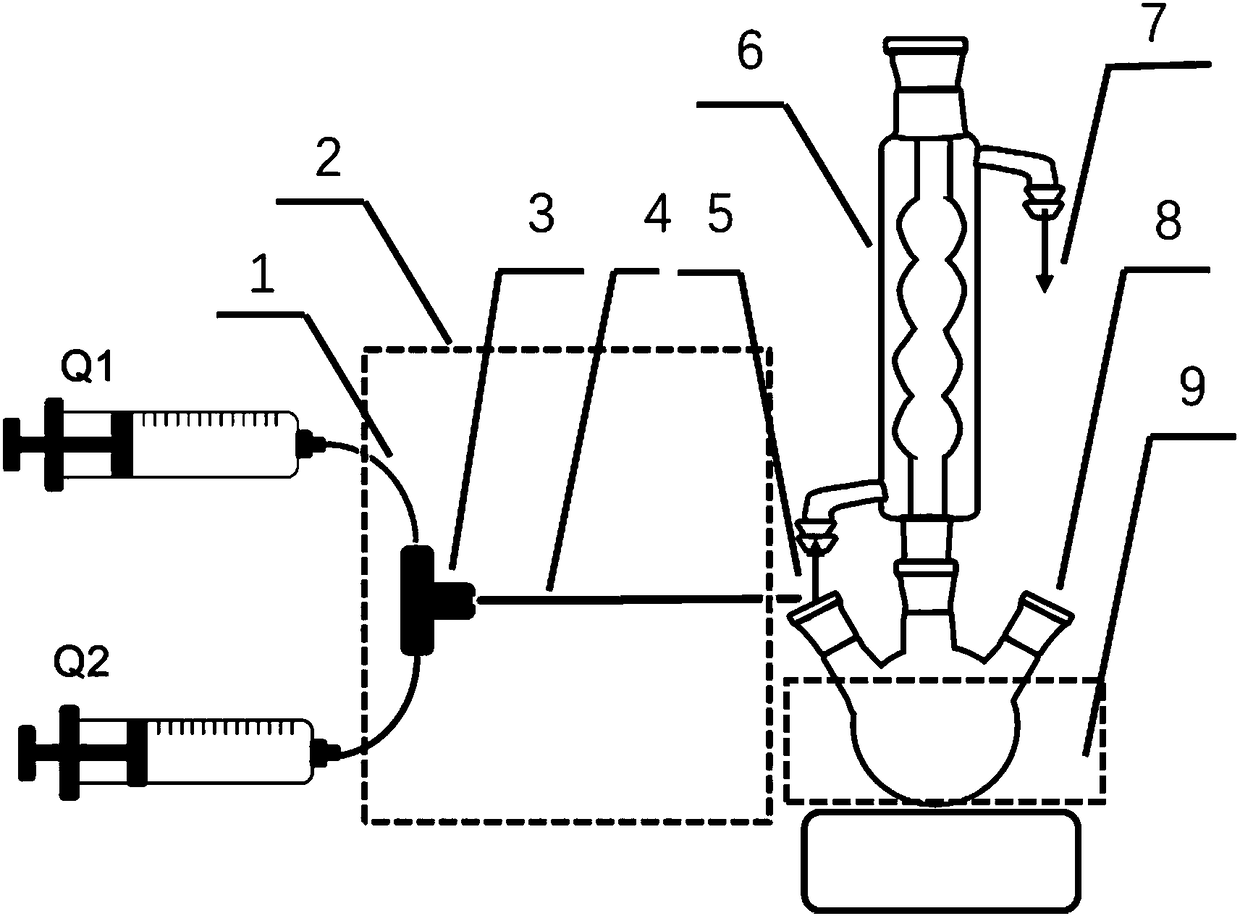

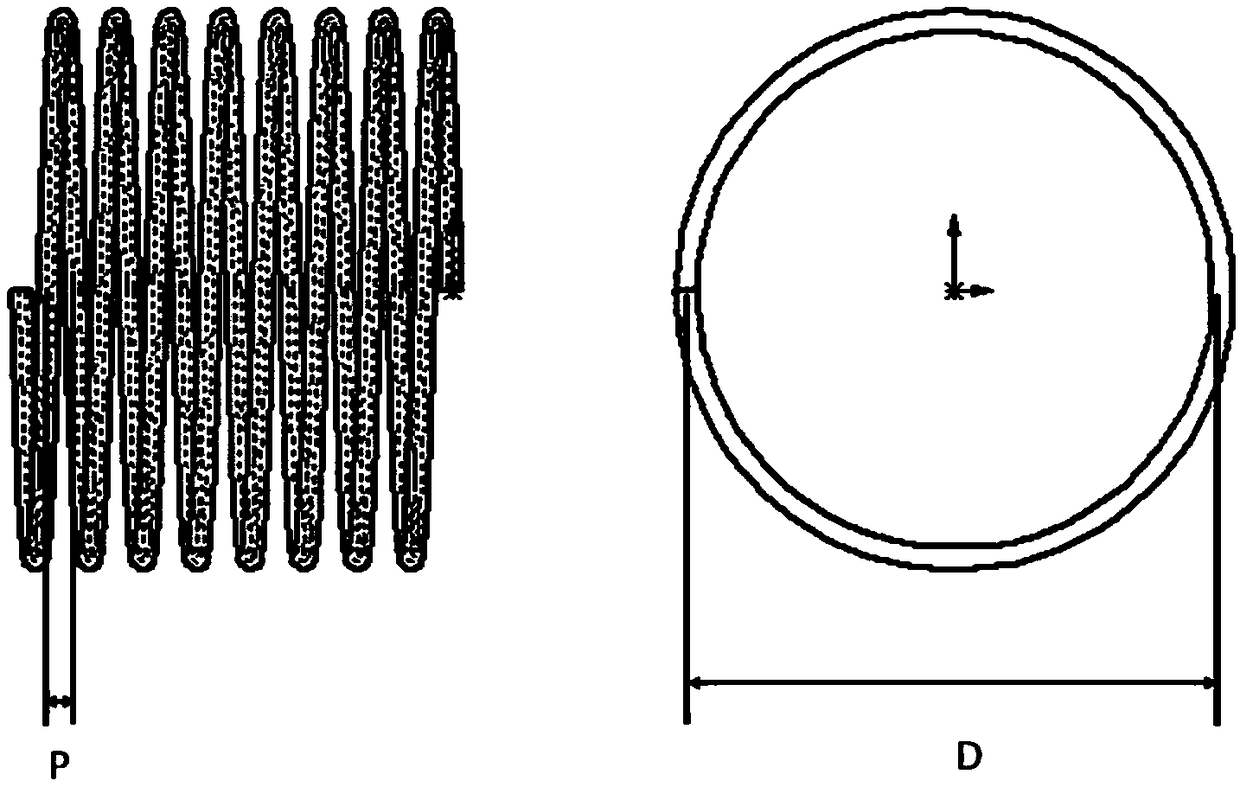

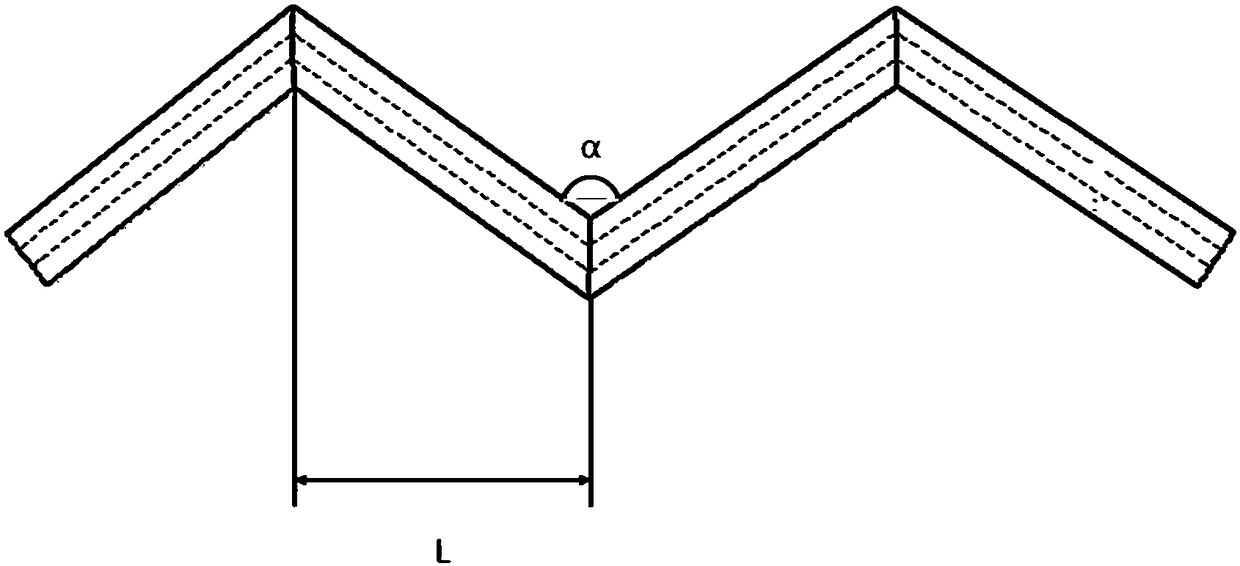

[0030] In the reactor 1 shown in the figure, the capillary is 1000 mm long and arranged in a folded line with a bend angle of 120° and a pitch of 80 mm. Such as figure 1 , sodium nitrite Q1, aniline salt and hydrochloric acid mixed solution Q2 are respectively injected into a T-shaped micro-mixer with an inner diameter of 0.5mm through a fluid pump, and the injection volume flow rate is 8mL / min, and the molar ratio is sodium nitrite: aniline: Hydrochloric acid=1:1.01:2.15. The capillary microchannel is built in a water bath at 15°C to make the reaction process reach the state, and the obtained diazonium solution is directly injected into the reduction reaction kettle for subsequent reactions. The reaction kettle contains a mixture of ammonium sulfite and ammonium bisulfite prepared in advance. After the reactor has collected a certain amount of mixed fluid from the microreactor, continue to keep warm at 80°C for 1 hour, and finally add strong acid to keep warm for 15 minutes...

Embodiment 2

[0032] In the reactor 2 shown in the figure, the capillary is 1000mm long and is helical. The diameter of the helix is 80mm and the pitch is 30mm. Such as figure 1 , sodium nitrite Q1, aniline salt and hydrochloric acid mixed solution Q2 are respectively injected into a T-shaped micro-mixer with an inner diameter of 0.5 mm through a fluid pump, and the injection volume flow rate is 10 mL / min, and the molar ratio is sodium nitrite: aniline: Hydrochloric acid=1:1.01:2.15. The capillary microchannel is built in a water bath at 20°C to make the reaction process reach the state, and the obtained diazonium solution is directly injected into the reduction reaction kettle for subsequent reactions. The reaction kettle contains a mixture of ammonium sulfite and ammonium bisulfite prepared in advance. After the reactor has collected a certain amount of mixed fluid from the microreactor, continue to keep warm at 80°C for 1 hour, and finally add strong acid to keep warm for 15 minutes...

Embodiment 3

[0034] In reactor 3 as shown in the figure, the capillary is 1000mm long and is in a straight line, such as figure 1 , sodium nitrite Q1, aniline salt and hydrochloric acid mixed solution Q2 are respectively injected into a T-shaped micro-mixer with an inner diameter of 0.5 mm through a fluid pump, and the injection volume flow rate is 8 mL / min, and the molar ratio is sodium nitrite: aniline: hydrochloric acid =1:1.01:2.15. The capillary microchannel is built in a 30°C water bath to make the reaction process reach the state, and the obtained diazonium solution is directly injected into the reduction reaction kettle for subsequent reactions. The reaction kettle contains a mixture of ammonium sulfite and ammonium bisulfite prepared in advance. After the reactor has collected a certain amount of mixed fluid from the microreactor, continue to keep warm at 80°C for 1 hour, and finally add strong acid to keep warm for 15 minutes. The sample was obtained after cooling crystallizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com