Polyethylene glycol and anticoagulant polypeptide surface modified gold material and preparation method

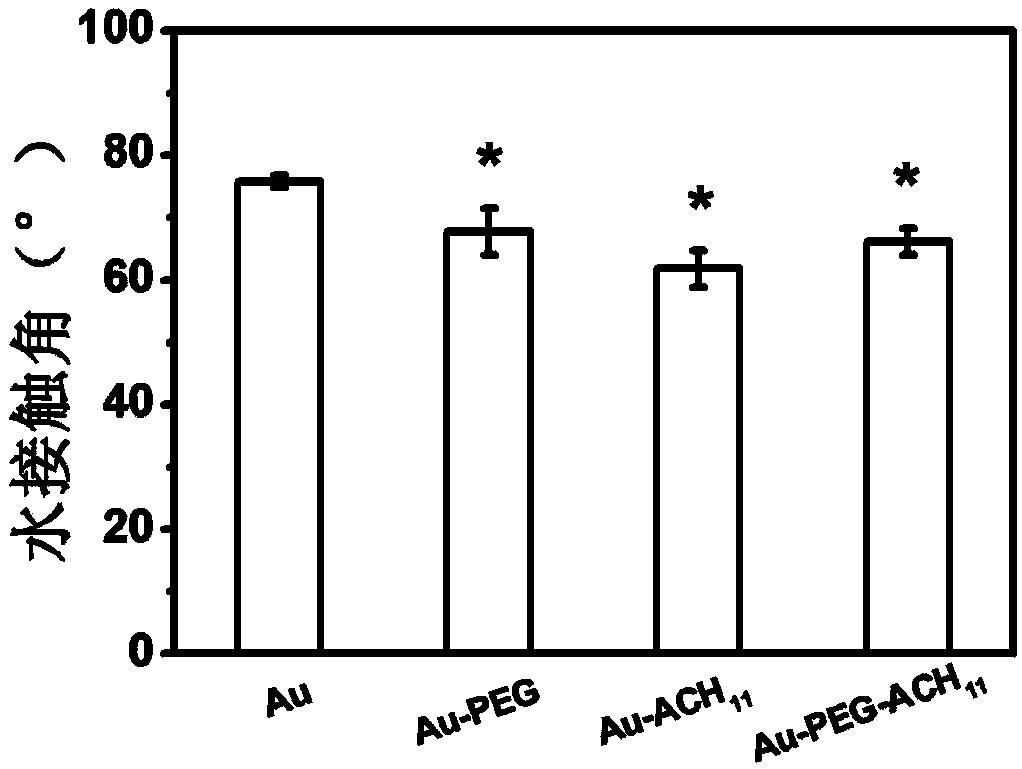

A polyethylene glycol and surface modification technology, applied in the field of surface modification of anticoagulant biomaterials, blood contact materials and biocompatibility modification, to achieve resistance to adhesion and activation, reduction of water contact angle, The effect of excellent hydrophilic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

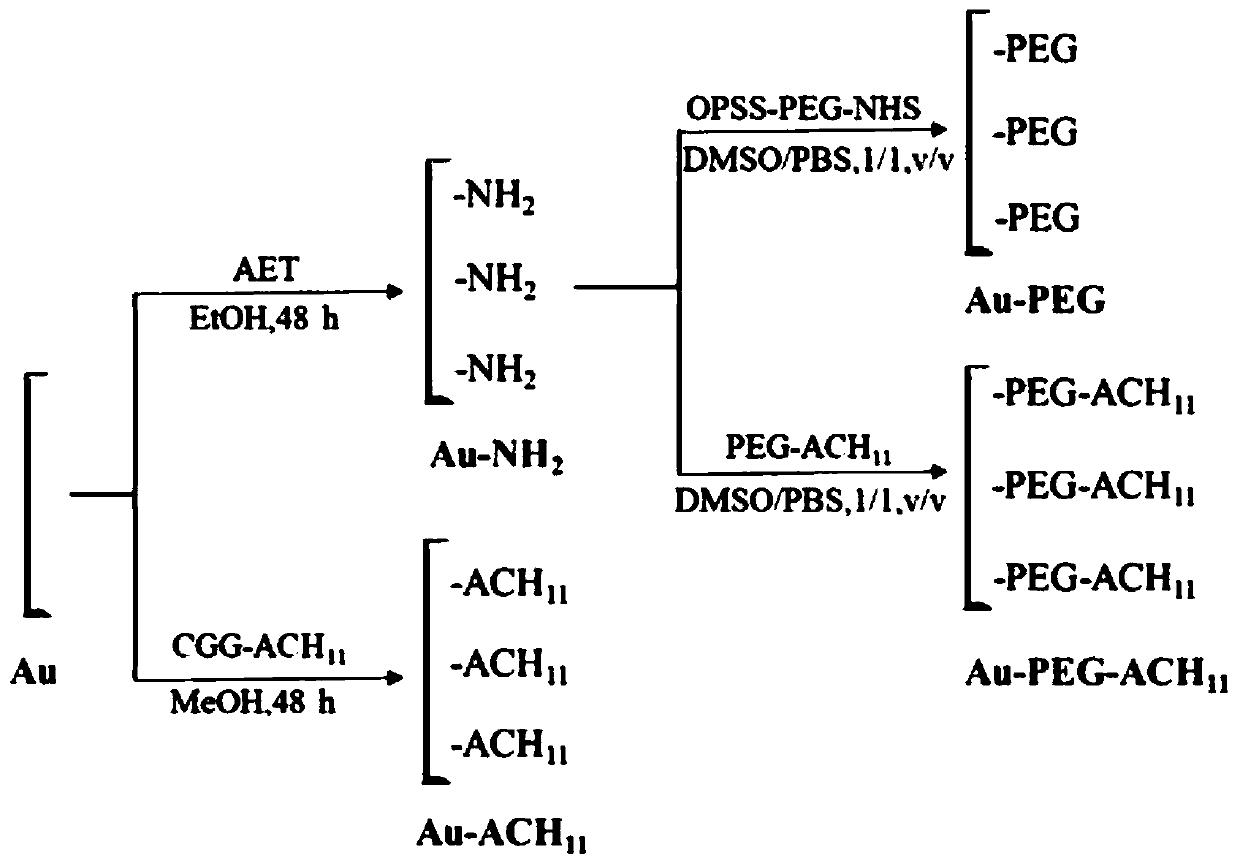

Method used

Image

Examples

Embodiment 1

[0058] First, treat the gold substrate—the gold substrate with a diameter of 10 mm, a thickness of 2 mm, and surface polishing treatment is ultrasonically treated in ethanol for 5 minutes, then placed in a mixed solution of hydrogen peroxide and sulfuric acid, dipped for 10 minutes, and then cleaned with boiling water. Standby; where hydrogen peroxide is an aqueous solution with a mass percentage of hydrogen peroxide of 15%, sulfuric acid is an aqueous solution of sulfuric acid with a concentration of 3mol / L, and the volume ratio of hydrogen peroxide and sulfuric acid is 3:7; methanol is used as a solvent, and the concentration of preparation is 0.5mg / mL of CGG-ACH 11 Solution, CGG-ACH 11 The amino acid sequence is CGG-LTFPRIVFVLG.

[0059] Secondly, prepare the OPSS-PEG-NHS solution with a concentration of 2.0mg / mL, the solvent is a mixed solution of DMSO and 0.01M PBS aqueous solution, the volume ratio of the two is 1:1, DMSO is the abbreviation of dimethyl sulfoxide, OPSS...

Embodiment 2

[0075] (1) A gold substrate with a diameter of 10 mm, a thickness of 2 mm, and surface polishing treatment was ultrasonically treated in EtOH for 10 min, then dipped in solution 1 for 20 min, and then cleaned with boiling water. The EtOH is the abbreviation of ethanol; The solution 1 is H 2 o 2 (10%) and H 2 SO 4 (2M) mixed solution, the volume ratio is 4:6;

[0076] (2) Using MeOH as solvent, prepare CGG-ACH with a concentration of 2.0mg / mL 11 solution to obtain solution 2. The MeOH is the abbreviation of methanol; the CGG-ACH 11 The amino acid sequence is CGG-LTFPRIVFVLG;

[0077] (3) Under a nitrogen atmosphere, dry the product of step (1) and immerse it in solution 2, and react at 20°C for 24 hours to obtain Au-ACH 11 product.

[0078] (4) Under a nitrogen atmosphere, dry the product of step (1) and soak it in 30 mg / mL AET solution. After reacting at 30°C for 24 hours, wash it with deionized water and absolute ethanol three times and dry it in vacuum for 12 hours t...

Embodiment 3

[0086] (1) A gold substrate with a diameter of 10mm, a thickness of 2mm, and a surface polishing treatment was ultrasonicated in ethanol for 15 minutes, dipped in solution 1 for 30 minutes, and then cleaned with boiling water. The solution 1 is H 2 o 2 (20%) and H 2 SO 4 (5M) mixed solution, the volume ratio is 3:7;

[0087] (2) Using MeOH as solvent, prepare CGG-ACH with a concentration of 1.5mg / mL 11 , to obtain solution 2. The MeOH is the abbreviation of methanol; the CGG-ACH 11 The amino acid sequence is CGG-LTFPRIVFVLG;

[0088] (3) Under a nitrogen atmosphere, dry the product of step (1) and immerse it in solution 2, and react at 30°C for 48 hours to obtain Au-ACH 11 product.

[0089] (4) Under a nitrogen atmosphere, dry the product of step (1) and immerse it in a 50 mg / mL AET solution. After reacting at 30°C for 48 hours, wash it with deionized water and absolute ethanol three times and dry it in vacuum for 12 hours to obtain Au-NH 2 product. Described AET sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com