Intermediate infrared luminescent material for rare earth ion doped glass ceramics and preparation method of intermediate infrared luminescent material

An infrared luminescence, glass-ceramic technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of low luminous efficiency of ordinary quartz glass, inability to draw optical fibers, and harsh crystal material preparation conditions, etc. The effect of enhanced luminous efficiency, good optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

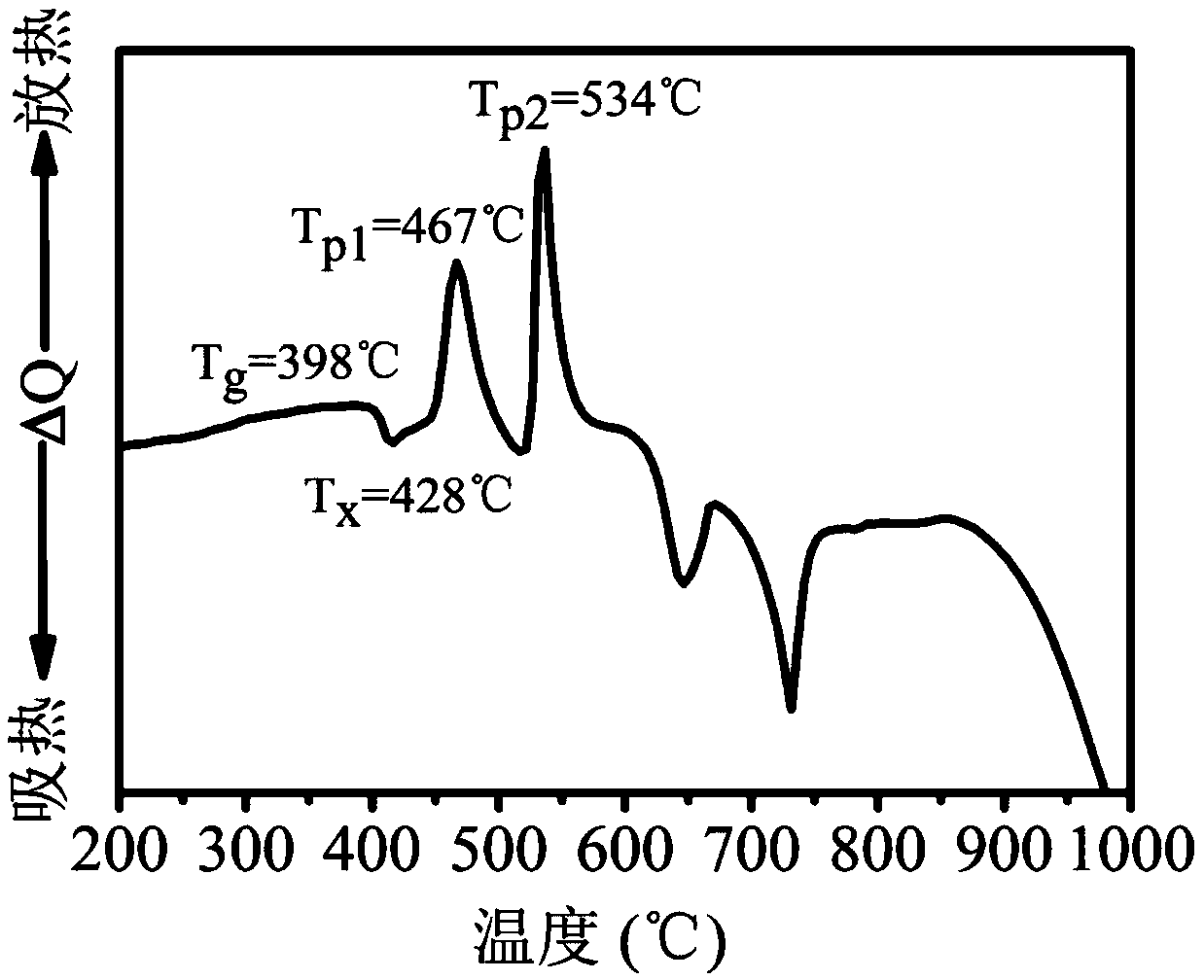

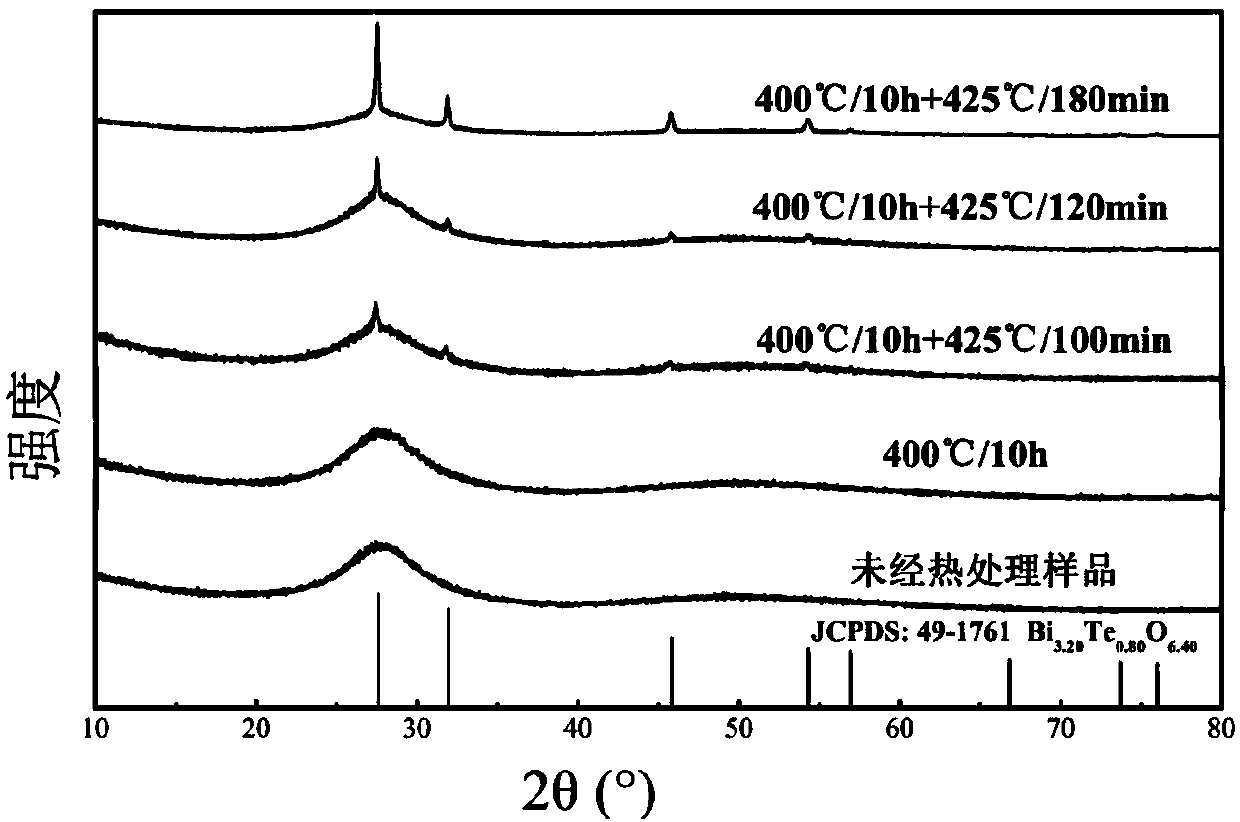

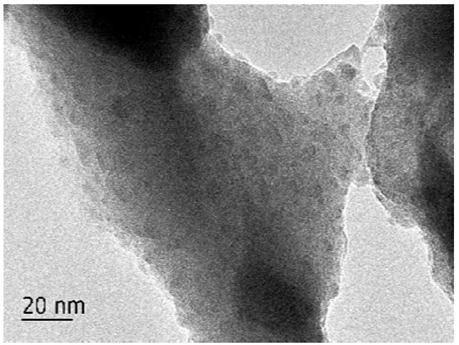

[0034] By composition 75TeO 2 -12.5Nb 2 o 5 -12.5Bi 2 o 3 (mol%) Weigh 60g of required TeO 2 , Nb 2 o 5 , Bi 2 o 3 , Er 2 o 3 Powder raw material (99.99% pure), Er 2 o 3Add 0.75 mol% according to the molar ratio, mix well, put it into a crucible with a cover, put it at 850°C and melt for 30 minutes, then quickly cast the glass solution onto a stainless steel template that has been preheated to 200°C, and place it in the muffle The furnace was kept at 380°C for two hours, and the temperature was cooled to room temperature at a rate of 5°C / min to obtain bismuth tellurite glass containing rare earth ions, which was then cut and polished; The tellurium bismuth salt glass containing rare earth ions is heat-treated at 400°C for 10h (glass transition temperature Tg=398°C), then heat-treated at 425°C for 180min (crystallization temperature Tc=428°C), and naturally cooled to room temperature to obtain transparent crystallites Glass. Under the same conditions, the heat tre...

Embodiment 2

[0037] By composition 75TeO 2 -12.5Nb 2 o 5 -12.5Bi 2 o 3 (mol%) Weigh 60g of required TeO 2 ,Nb 2 o 5 , Bi 2 o 3 ,Er 2 o 3 Powder raw material (99.99% pure), Er 2 o 3 Add 0.5mol% according to the molar ratio, mix well, put it into a crucible with a cover, put it at 850°C and melt for 30min, then quickly cast the glass solution onto a stainless steel template that has been preheated to 200°C, and after forming, put it in a muffle The furnace was kept at 380°C for two hours, and the temperature was cooled to room temperature at a rate of 5°C / min to obtain bismuth tellurite glass containing rare earth ions, which was then cut and polished; The bismuth tellurite glass containing rare earth ions was heat-treated at 400°C for 10 hours, then heat-treated at 425°C for 180 minutes, and cooled naturally to room temperature to obtain transparent glass-ceramics. Under the same conditions, the heat treatment time at 425 °C was replaced by 120, 100 and 0 min.

[0038] The rar...

Embodiment 3

[0040] By composition 65TeO 2 -20Nb 2 o 5 -15Bi 2 o 3 (mol%) Weigh 60g of required TeO 2 ,Nb 2 o 5 , Bi 2 o 3 ,Er 2 o 3 Powder raw material (99.99% pure), Er 2 o 3 Add 0.4mol% according to the molar ratio, mix well, put it into a crucible with a cover, place it at 1000°C and melt for 45min, then quickly cast the glass solution onto a stainless steel template that has been preheated to 200°C, and place it in the muffle The furnace was kept at 380°C for two hours, and the temperature was cooled to room temperature at a rate of 10°C / min to obtain bismuth tellurite glass containing rare earth ions, which was then cut and polished; The bismuth tellurate glass containing rare earth ions is heat-treated at around 400°C for 10 hours, then heat-treated at 423°C for 180 minutes, and cooled naturally to room temperature to obtain transparent glass-ceramics. Under the same conditions, the heat treatment time at 423 °C was replaced by 120, 100 and 0 min.

[0041] The rare ear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com