Method for radiation degradation of xanthan gum through electron beams

A technology of electron beam radiation and xanthan gum, which is applied in the field of electron beam radiation to degrade xanthan gum, can solve the problems of increased crude oil density, slow dissolution, increased viscosity, etc., and achieves increased free radical scavenging rate and improved antioxidant performance , The effect of increasing the reducing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Irradiation Degradation of Solid Xanthan Gum

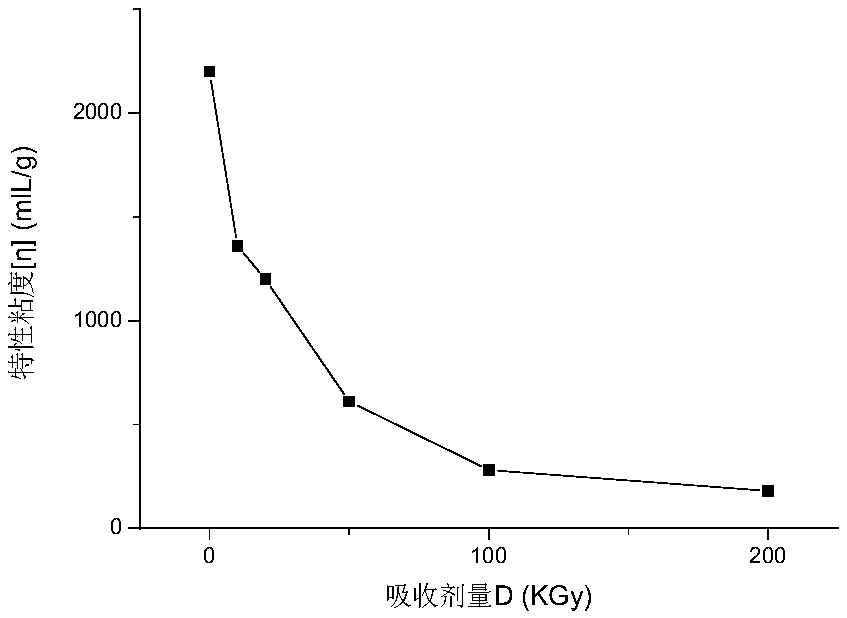

[0018] The solid Fufeng xanthan gum is directly irradiated and degraded by electron beams, and the relationship between its intrinsic viscosity [η] and absorbed dose D is shown in figure 1 ;

[0019] figure 1 It can be seen in the figure that the intrinsic viscosity [η] decreases with the increase of the absorbed dose D, and the absorbed dose D is in the stage of 0-50KGy, and the intrinsic viscosity [η] decreases rapidly with the increase of the absorbed dose D, from about 2000mL / g to about 550mL and when the absorbed dose D was greater than 100KGy, the intrinsic viscosity [η] decreased slowly with the increased absorbed dose D, and was about 180mL / g at 200KGy, indicating that the radiation could degrade the xanthan gum, but a relatively high A low intrinsic viscosity [η] requires a larger irradiation dose. (concentration of xanthan gum solution 1.5mg / mL when measuring intrinsic viscosity)

Embodiment 2

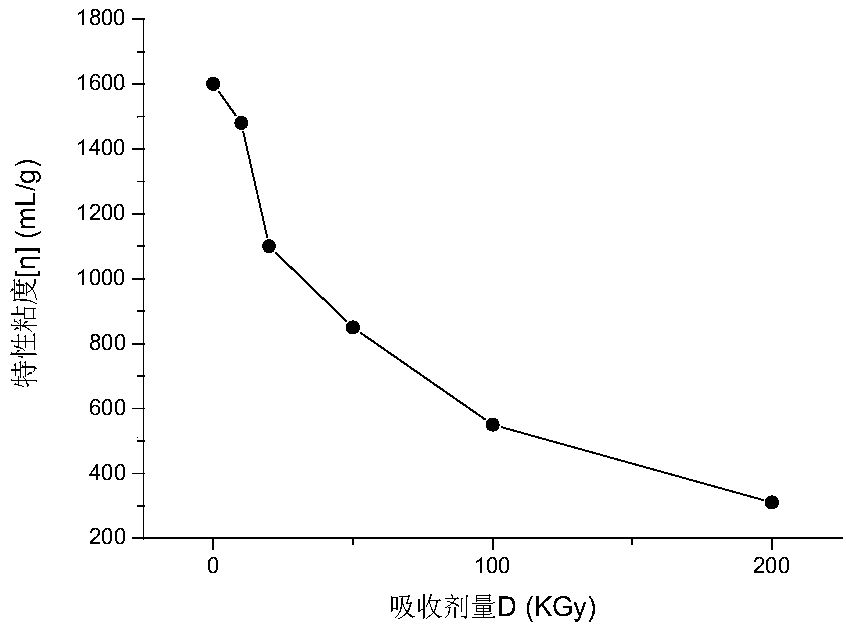

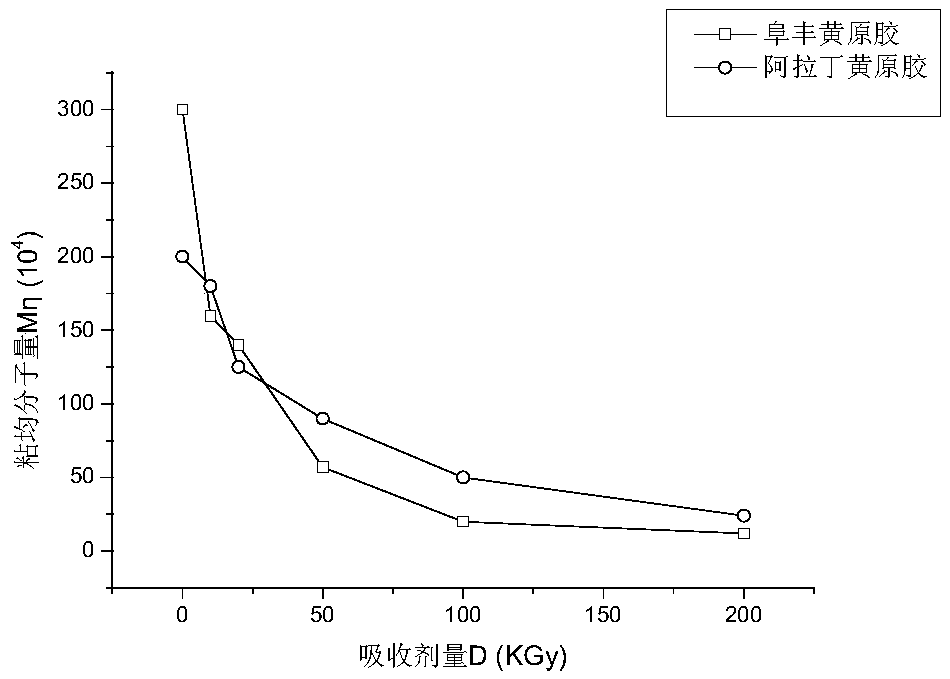

[0021] Irradiation Degradation of Solid Xanthan Gum with Different Specifications

[0022] In order to compare the radiation degradation of xanthan gum produced by different processes, this example tested the intrinsic viscosity [η] and absorption of different xanthan gums such as Zhongxuan 9290 (food grade), a certain American brand (food grade), and Aladdin (ups). The relationship between dose D, the results confirmed that no matter what kind of xanthan gum, the intrinsic viscosity [η] decreases with the increase of absorbed dose D. The trend of decline remains unchanged, but the rate of decline is different. figure 2 It is the relationship between the intrinsic viscosity [η] of Aladdin xanthan gum and the absorbed dose D, the intrinsic viscosity [η] of unirradiated xanthan gum is about 1600mL / g, and it is about 320mL / g at 200KGy. and figure 1 It can be seen from the comparison that the decrease rate of Aladdin intrinsic viscosity [η] is lower than that of Fufeng xanthan g...

Embodiment 3

[0024] Irradiation Degradation of Liquid Xanthan Gum

[0025] In order to observe the radiation degradation characteristics of liquid xanthan gum, Fufeng and Aladdin xanthan gums were respectively selected to form 1mg / mL sodium chloride aqueous solution, and different doses of irradiation tests were carried out. The outflow time, see Table 1.

[0026] Table 1 The relationship between liquid xanthan gum absorbed dose D and outflow time

[0027]

[0028] It can be seen from Table 1 that no matter it is Fufeng or Aladdin, the outflow time of liquid xanthan gum after radiation is only slightly longer than that of the solvent when the absorbed dose D=2.5KGy. At this time, the intrinsic viscosity [η]=47.5mL calculated according to the formula / g. All other doses are the same as the solvent, so the Ubbelohde viscometer is not suitable for directly measuring the intrinsic viscosity [η] after such liquid xanthan gum is irradiated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com