A genetic engineering strain of Bacillus subtilis and its application in the preparation of small molecule hyaluronic acid

A technology of genetically engineered bacteria and Bacillus subtilis, which is applied in genetic engineering, application, and plant gene improvement, can solve the problems of low expression, inclusion bodies, and low enzyme activity, and achieve simple operation, increased profit margins, and reduced The effect of the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

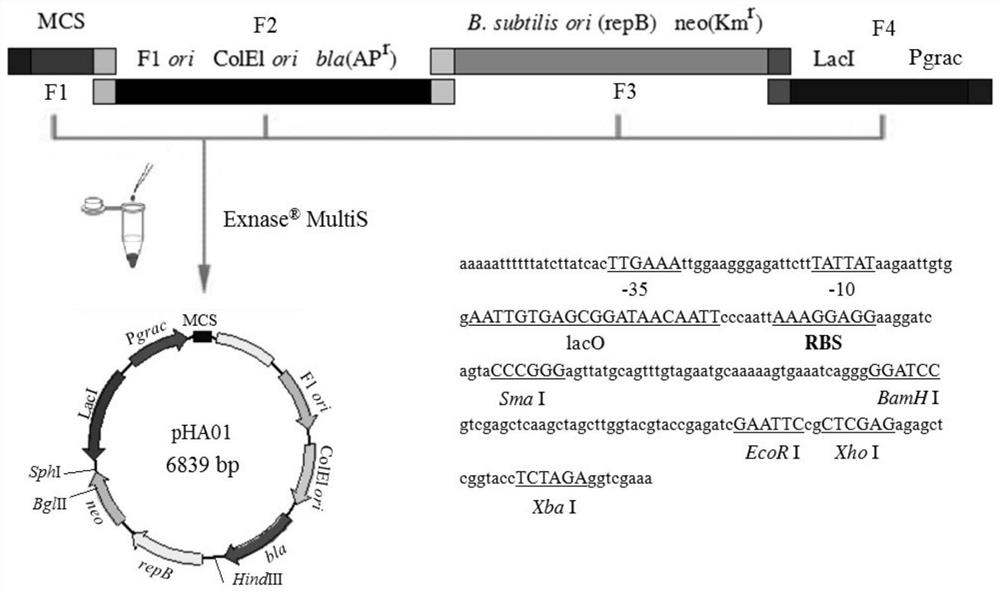

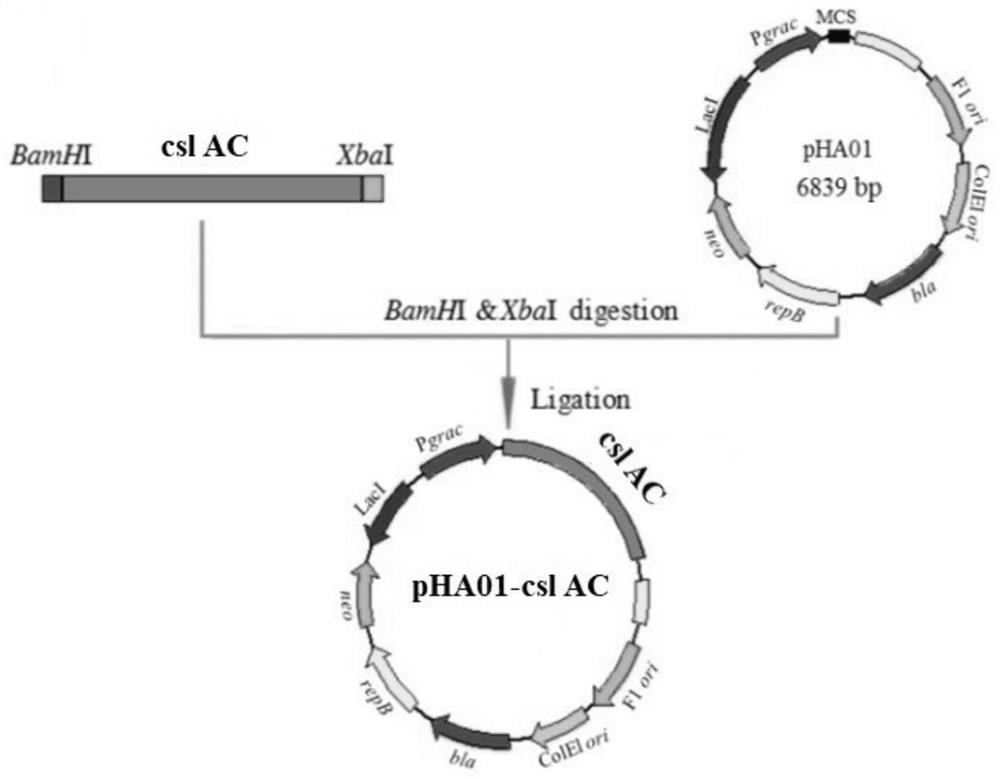

[0082] Example 1: Construction of recombinant Bacillus subtilis.

[0083] Utilize the GeneRunner software to design primers, design primers (P1, P2 and P3, P4) according to the plasmid pMA5 gene sequence to synthesize fragments F1 and F2 respectively; design primers (P5, P6) to synthesize fragment F3 according to the pHT43 gene sequence; Sequence design primers (P7, P8) to synthesize fragment F4; design primers (P9, P10) to synthesize fragment F5 according to the gene (csl AC) of chondroitin sulfate AC lyase in the genome of P. heparinus ATCC13125.

[0084] Table 2-3 Primers required for recombinant plasmid construction

[0085] Table 2-3 Primers used for the recombinant plasma construction

[0086]

[0087] (1) Construction of shuttle plasmid pHA03

[0088] Amplification of F1 gene fragments: Add reagents according to Table 2 in a 0.2 mL Eppendorf tube. The pMA5 plasmid used as the template DNA was extracted by a quick plasmid extraction kit. The PCR cycle parameters w...

Embodiment 2

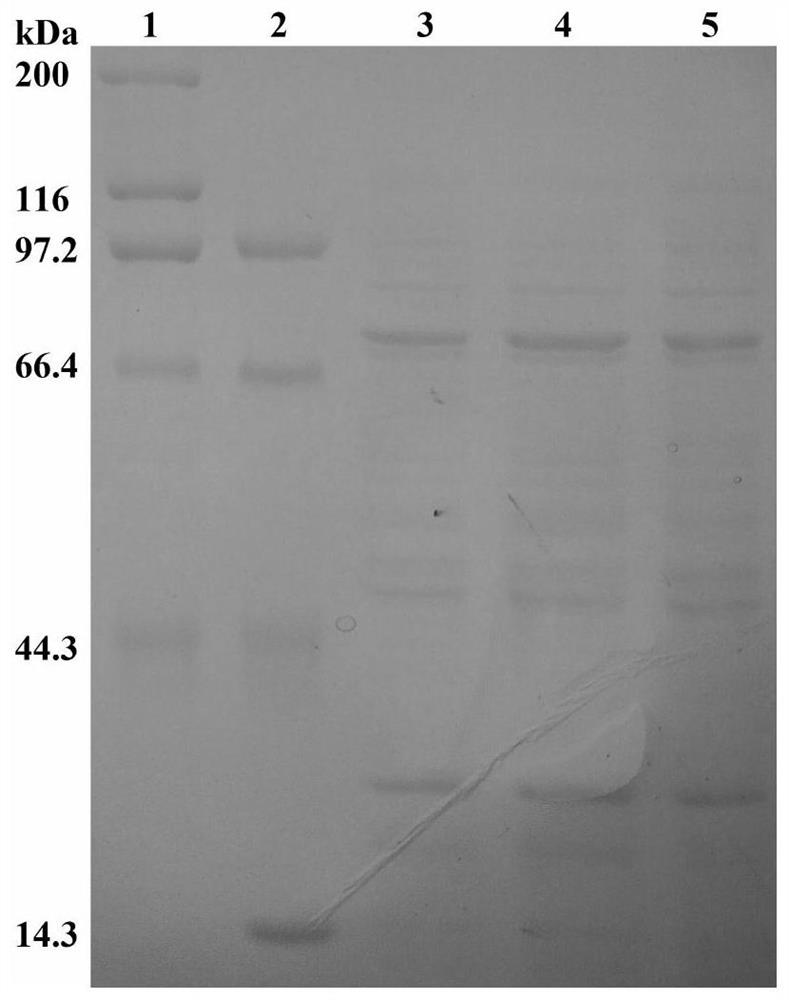

[0102] Example 2: Induced expression of chondroitin sulfate AC lyase

[0103] Inoculate the constructed recombinant Bacillus subtilis B. subtilis WB800-△spoOA-pHA03-csl AC in LB liquid medium containing kanamycin sulfate resistance, culture overnight at 37°C; then transfer with 4% inoculum into 1L of fermentation medium containing kanamycin sulfate, and ferment for 2 to 4 hours to OD 660 When it reaches 0.6, add 8g / L IPTG or lactose to induce expression for 24h, and the activity of chondroitin sulfate AC lyase in the supernatant of the fermentation broth can reach 16U / mL.

Embodiment 3

[0104] Embodiment 3: the chondroitin sulfate AC lyase activity assay of fermented liquid

[0105] Take 1mL of fermentation broth and centrifuge, take 0.1mL supernatant and 7.9mL 1g / L chondroitin sulfate A (prepared with 0.02mol / LTris-HCL, pH 7.5) respectively, add them to a 15mL colorimetric tube, place at 37 React in a water bath at ℃ for 20 minutes, immediately place it in a boiling water bath and boil for 5 minutes, add inactivated fermentation broth supernatant to the control tube under the same conditions, and measure the light absorption value at 232 nm. The enzyme activity unit U is defined as the amount of enzyme required to catalyze the formation of 1 μmol of unsaturated disaccharide per minute at 37°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com