Microalloying gold and tin alloy material and preparation method thereof

A technology of microalloying and tin alloying, which is applied in the field of tin alloy materials and microalloying gold-tin alloys, can solve problems such as difficult to meet the requirements of eutectic composition, complicated process, and relative content changes, so as to improve the processing and forming performance , to meet the high performance requirements, the effect of uniform solidification structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

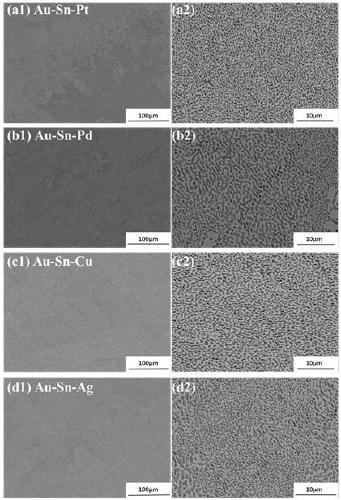

[0046] This embodiment is a method for preparing a microalloyed Au-Sn-Pt alloy with a Pt content of 50 ppm and its foil, including the following steps:

[0047] Step (1), preparation of gold-tin eutectic alloy

[0048] Weigh a certain amount of Au with a purity of 99.99% and Sn with a purity of 99.99% with an electronic balance, prepare Au and Sn according to the mass ratio of 80:20 and place them in a graphite crucible, and then place the graphite crucible in The middle part of the induction coil of the vacuum high-frequency induction furnace is evacuated to 3.6×10 -4 Pa, turn on the power for vacuum induction melting, and cool down with the furnace after melting. The smelting process was repeated three times to obtain a gold-tin eutectic alloy with uniform composition.

[0049] Step (2), master alloy preparation

[0050] Weigh a certain amount of Au with a purity of 99.99% and Pt with a purity of 99.99% with an electronic balance, prepare Au and Pt in a mass ratio of 99:...

Embodiment 2

[0059] This embodiment is a method for preparing a microalloyed Au-Sn-Pt alloy with a Pt content of 200ppm and its foil, including the following steps:

[0060] Step (1), preparation of gold-tin eutectic alloy

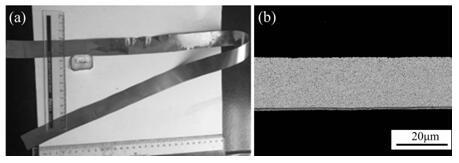

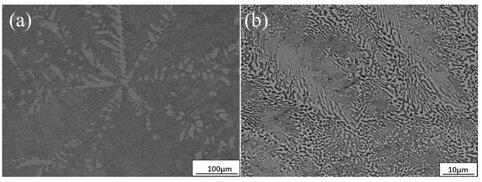

[0061] Weigh a certain amount of Au with a purity of 99.99% and Sn with a purity of 99.99% with an electronic balance, prepare Au and Sn according to the mass ratio of 80:20 and place them in a graphite crucible, and then place the graphite crucible in The middle part of the induction coil of the vacuum high-frequency induction furnace is evacuated to 3.6×10 -4 Pa, turn on the power for vacuum induction melting, and cool down with the furnace after melting. The smelting process was repeated four times to obtain a gold-tin eutectic alloy with uniform composition. The scanning electron microscope (SEM) photo of the obtained gold-tin eutectic alloy furnace cold-cast structure is as follows: figure 2 As shown, among them, figure 2 (a) Low-magnification tissue photog...

Embodiment 3

[0076] This embodiment is a method for preparing a microalloyed Au-Sn-Pt alloy with a Pt content of 500ppm and its foil, including the following steps:

[0077] Step (1), preparation of gold-tin eutectic alloy

[0078] Weigh a certain amount of Au with a purity of 99.99% and Sn with a purity of 99.99% with an electronic balance, prepare Au and Sn according to the mass ratio of 80:20 and place them in a graphite crucible, and then place the graphite crucible in The middle part of the induction coil of the vacuum high-frequency induction furnace is evacuated to 3.6×10 -4 Pa, turn on the power for vacuum induction melting, and cool down with the furnace after melting. The smelting process was repeated twice to obtain a gold-tin eutectic alloy with uniform composition.

[0079] Step (2), master alloy preparation

[0080] Weigh a certain amount of Au with a purity of 99.99% and Pt with a purity of 99.99% with an electronic balance, prepare Au and Pt in a mass ratio of 99:1 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com