Ce/Zr composite oxide, and preparation method and application thereof

A composite oxide and oxide technology, applied in chemical instruments and methods, separation methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the application defects of cerium zirconium composite oxides, Limit the life of the catalyst, the uneven dispersion of metal elements, etc. in the purification ability of automobile exhaust, so as to achieve the effect of enhancing anti-aging ability, increasing adsorption capacity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

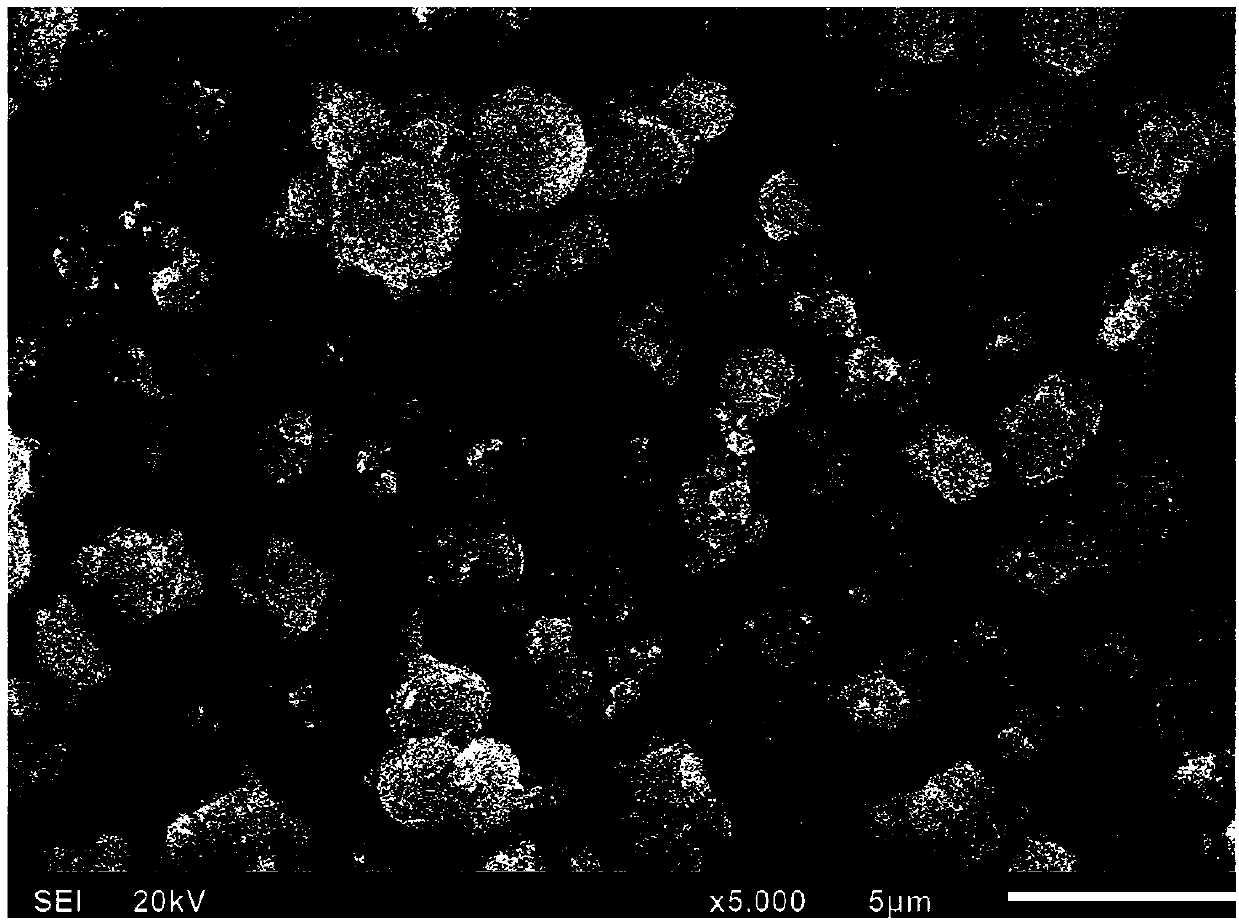

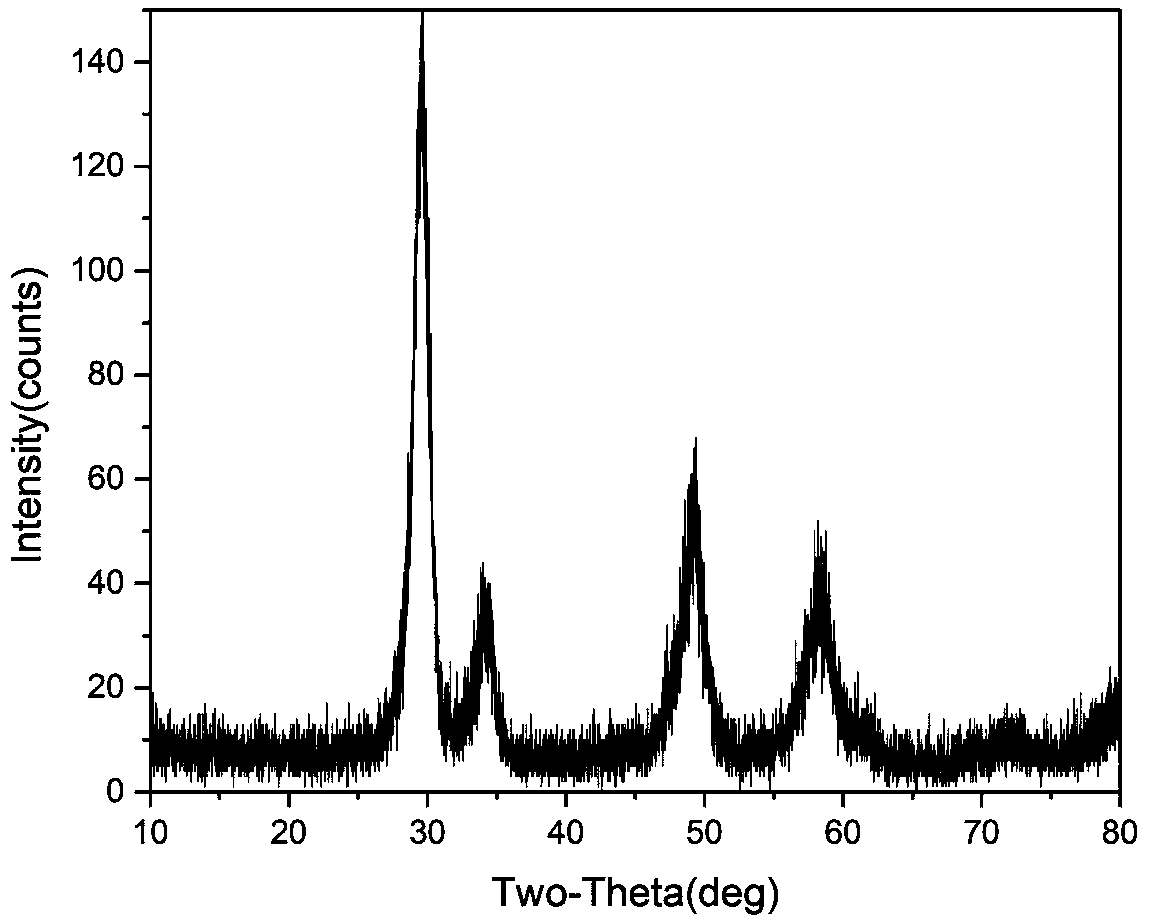

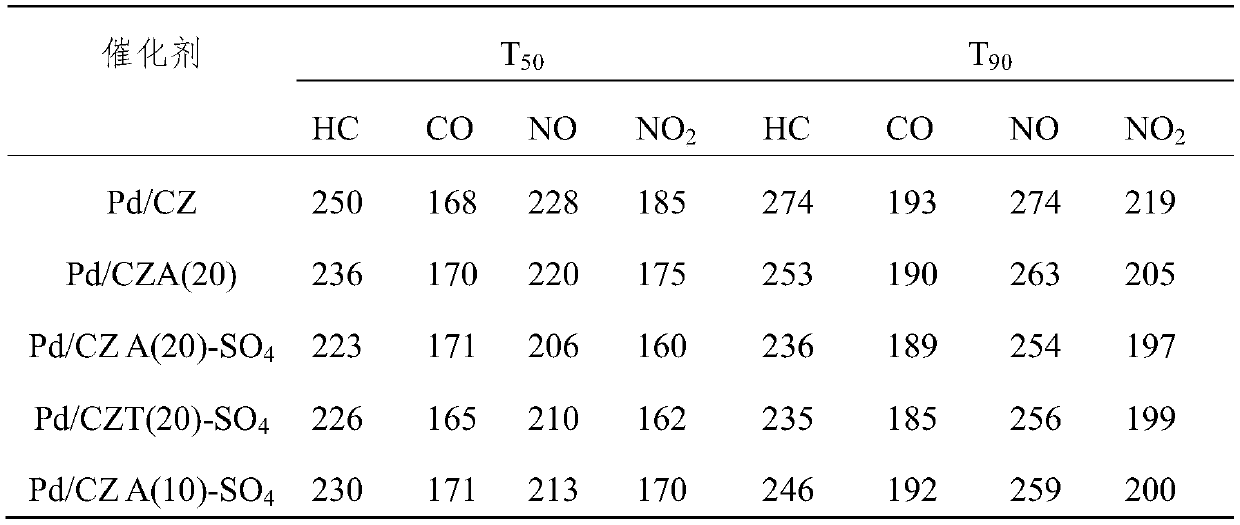

[0055] This embodiment provides a cerium-zirconium composite oxide and a preparation method thereof.

[0056] In the cerium-zirconium composite oxide: cerium oxide, zirconium oxide, aluminum oxide, lanthanum oxide, praseodymium oxide and sulfate radical, the specific proportions thereof are: 30%, 30%, 20%, 10%, 5%, 5%.

[0057] The preparation steps are as follows:

[0058] Put 300g of zirconium oxide corresponding to zirconia and 300g of cerium oxide corresponding to cerium ammonium nitrate solution in 2000mL ultrapure water, and raise the temperature of the solution to 90°C, and slowly add 200g of aluminum sulfate corresponding to aluminum oxide into the solution, Stir and age for 2h. The temperature of the solution was lowered to room temperature, and 100 g of lanthanum nitrate corresponding to lanthanum oxide was slowly added to the above solution, and 50 g of nitric acid spectrum aqueous solution corresponding to praseodymium oxide was added to the above solution to fina...

Embodiment 2

[0061] This embodiment provides a cerium-zirconium-titanium composite oxide and a preparation method thereof.

[0062] In the cerium-zirconium-titanium composite oxide: cerium oxide, zirconia, titanium oxide, lanthanum oxide, praseodymium oxide and sulfate radical, the specific proportions are: 30%, 30%, 20%, 10%, 5%, 5% .

[0063] The preparation steps are as follows:

[0064] Put 300g of zirconium oxide corresponding to zirconia and 300g of cerium oxide corresponding to cerium ammonium nitrate solution in 2000mL ultrapure water, and raise the temperature of the solution to 90°C, and slowly add 200g of titanium sulfate corresponding to titanium oxide into the solution, Stir and age for 2h. The temperature of the solution was lowered to room temperature, and 100 g of lanthanum nitrate corresponding to lanthanum oxide was slowly added to the above solution, and 50 g of nitric acid spectrum aqueous solution corresponding to praseodymium oxide was added to the above solution to...

Embodiment 3

[0066] This embodiment provides a cerium-zirconium composite oxide and a preparation method thereof.

[0067] In the cerium-zirconium composite oxide: cerium oxide, zirconium oxide, aluminum oxide, lanthanum oxide, praseodymium oxide and sulfate radical, the specific proportions thereof are: 30%, 40%, 10%, 10%, 5%, 5%.

[0068] The preparation steps are as follows:

[0069] The specific implementation is the same as in Example 1, the zirconium nitrate corresponding to 300g zirconia and the aluminum sulfate corresponding to 200g aluminum oxide are replaced with the corresponding aluminum nitrate corresponding to 400g zirconium oxide and 100g aluminum oxide, other ingredients and operation methods are all the same as Embodiment 1 is consistent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Oxygen storage capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com