High-dispersion multiple slow release type stable urea, production device and production technology

A stable and slow-release technology, applied in fertilization devices, urea compound fertilizers, applications, etc., can solve problems such as unfavorable industrial production and popularization, increase the production cost of stable fertilizers, and reduce the shelf life of stable fertilizers. The utilization rate of raw materials, the long-term effect, and the prolonged effect of slow-release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A high-dispersion multiple slow-release stable urea, production equipment and production process, which includes multiple slow-release agents and urea melts, and the weight ratio between the multiple slow-release agents and urea melts is: 5:1000 ; The multiple slow-release agent includes the following raw materials prepared in parts by weight: 1 part of urease inhibitor, 1 part of coating agent, 1 part of porogen and 22 parts of carrier, the urease inhibitor is NBPT, including The coating agent is polylactic acid, the porogen is polyethylene glycol, and the carrier is flour urea.

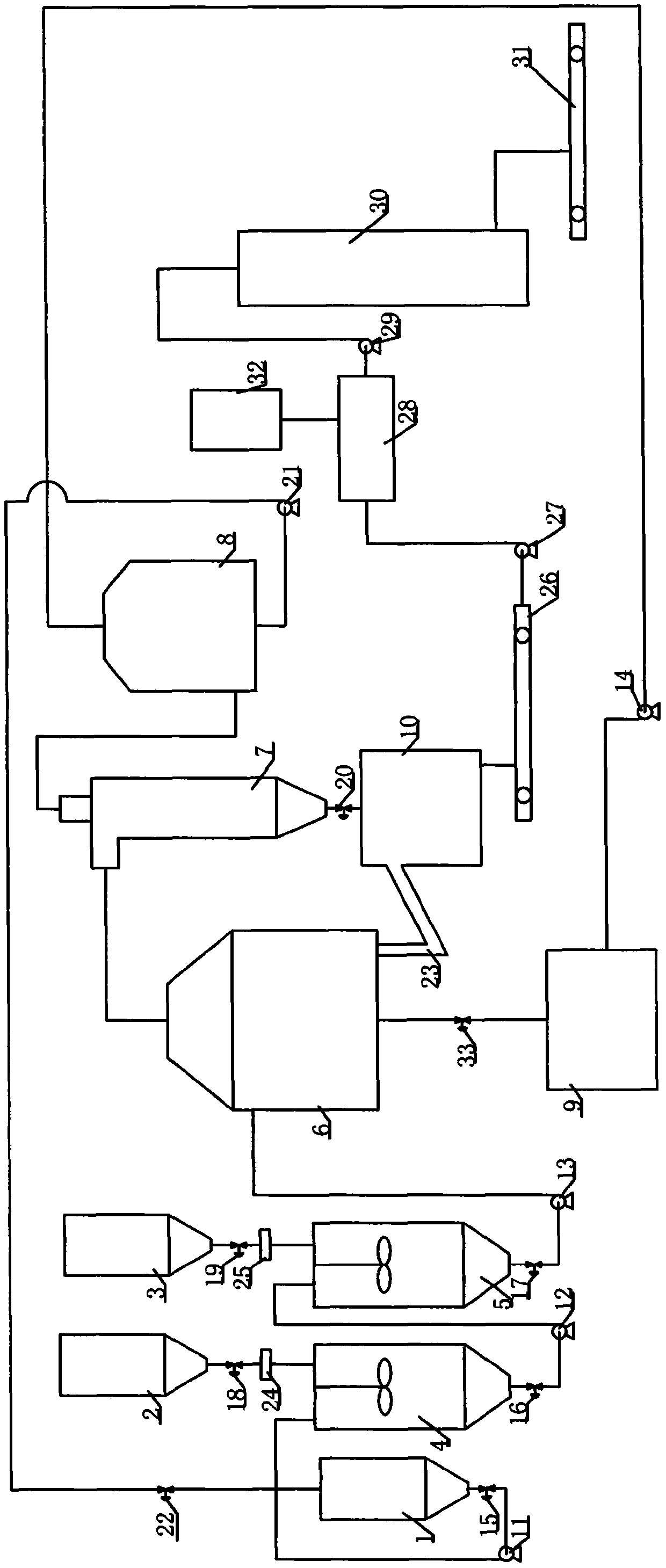

[0051] A production process of a high-dispersion multiple slow-release type stable urea production device, comprising the steps of:

[0052] Step 1: The ethanol in the solvent tank 1 enters the dissolving tank 4 through the first regulating valve 15 and the first flow pump 11, and the mixture in the first material tank 2 enters into the dissolving tank through the second regulating valve 18 a...

Embodiment 2

[0060] A high-dispersion multiple slow-release stable urea, production equipment and production process, which includes multiple slow-release agents and urea melts, and the weight ratio between the multiple slow-release agents and urea melts is: 10:1000 ; The multiple slow-release agent includes the following raw materials prepared in parts by weight: 3 parts of urease inhibitor, 2 parts of coating agent, 1.5 parts of porogen and 28 parts of carrier, the urease inhibitor is PPD, including The coating agent is ethyl cellulose, the porogen is hydroxypropyl cellulose, and the carrier is flour urea.

[0061] A production process of a high-dispersion multiple slow-release type stable urea production device, comprising the steps of:

[0062] Step 1: The ethanol in the solvent tank 1 enters the dissolving tank 4 through the first regulating valve 15 and the first flow pump 11, and the mixture in the first material tank 2 enters into the dissolving tank through the second regulating v...

Embodiment 3

[0070] A high-dispersion multiple slow-release stable urea, production equipment and production process, including multiple slow-release agents and urea melts, the weight ratio between the multiple slow-release agents and urea melts is: 7.5: 1000 The multiple slow-release agent includes the following raw materials prepared in parts by weight: 2 parts of urease inhibitor, 1.5 parts of coating agent, 1.25 parts of porogen and 25 parts of carrier, and the described urease inhibitor is boric acid, including The coating agent is cellulose acetate, the porogen is polyurethane, and the carrier is flour urea.

[0071] A production process of a high-dispersion multiple slow-release type stable urea production device, comprising the steps of:

[0072] Step 1: The ethanol in the solvent tank 1 enters the dissolving tank 4 through the first regulating valve 15 and the first flow pump 11, and the mixture in the first material tank 2 enters into the dissolving tank through the second regula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com