Phase change microcapsule simultaneously having magnetism and photo-thermal conversion feature and preparation method thereof

A technology of phase change microcapsules and light-to-heat conversion, which is applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of inability to achieve light-to-heat conversion energy storage and magnetic regulation, and single-function phase change microcapsules , to achieve the effect of improving supercooling phenomenon, good product uniformity and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

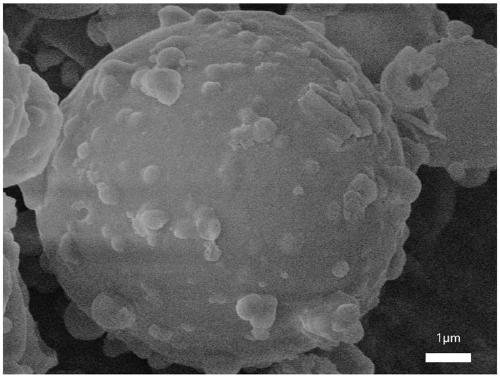

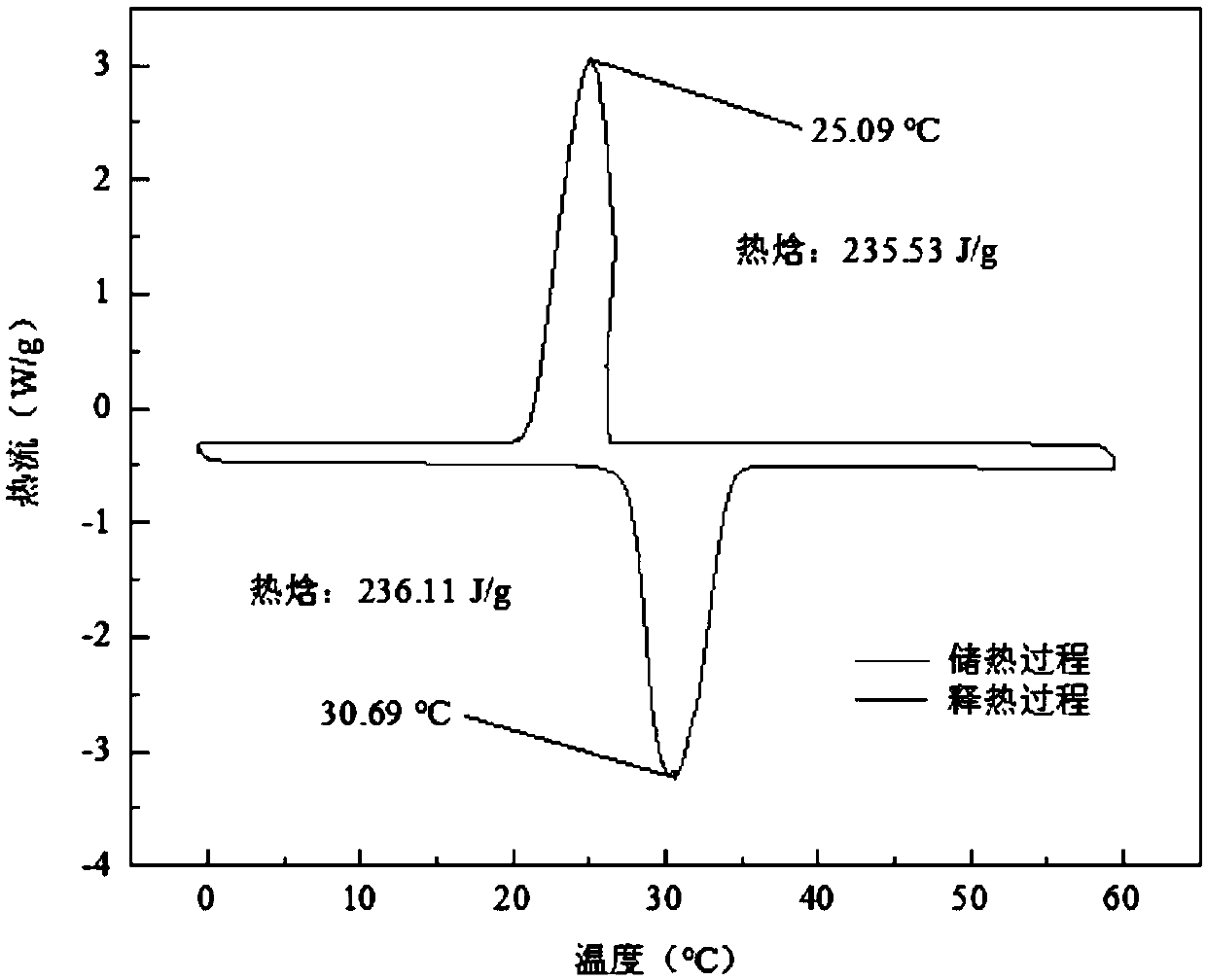

[0033] A phase-change microcapsule with both magnetic properties and light-to-heat conversion properties, comprising a wall material and a core material wrapped in the wall material, the core material comprising n-octadecane and oleic acid-coated ferric iron tetroxide nanoparticles , the wall material includes melamine formaldehyde resin and graphene oxide, and the mass ratio of the core material to the wall material is about 1:1.05. The preparation process is as follows:

[0034] (1) Phase change microcapsule core material pretreatment:

[0035] Weigh 2.322g FeCl respectively 3 ·6H 2 O, 0.8557gFeCl 2 4H 2 O and 150ml of deionized water were added to the three-necked flask, protected by nitrogen, and dissolved in a 60°C water bath with mechanical stirring at a speed of 600rpm, and then 6.19ml of ammonia water was added to 80ml of deionized water for dissolution and quickly poured into the three-necked flask. Continue to stir for 30 minutes, then add 6.4ml of oleic acid, i...

Embodiment 2

[0048] A phase-change microcapsule with both magnetic properties and light-to-heat conversion properties, comprising a wall material and a core material wrapped in the wall material, the core material comprising n-octadecane and oleic acid-coated ferric iron tetroxide nanoparticles , the wall material includes melamine formaldehyde resin and graphene oxide, and the mass ratio of the core material to the wall material is 1:1.05.

[0049] Its preparation method is the same as that of Example 1, except that the amount of ferric oxide coated with oleic acid is 0.3 g.

Embodiment 3

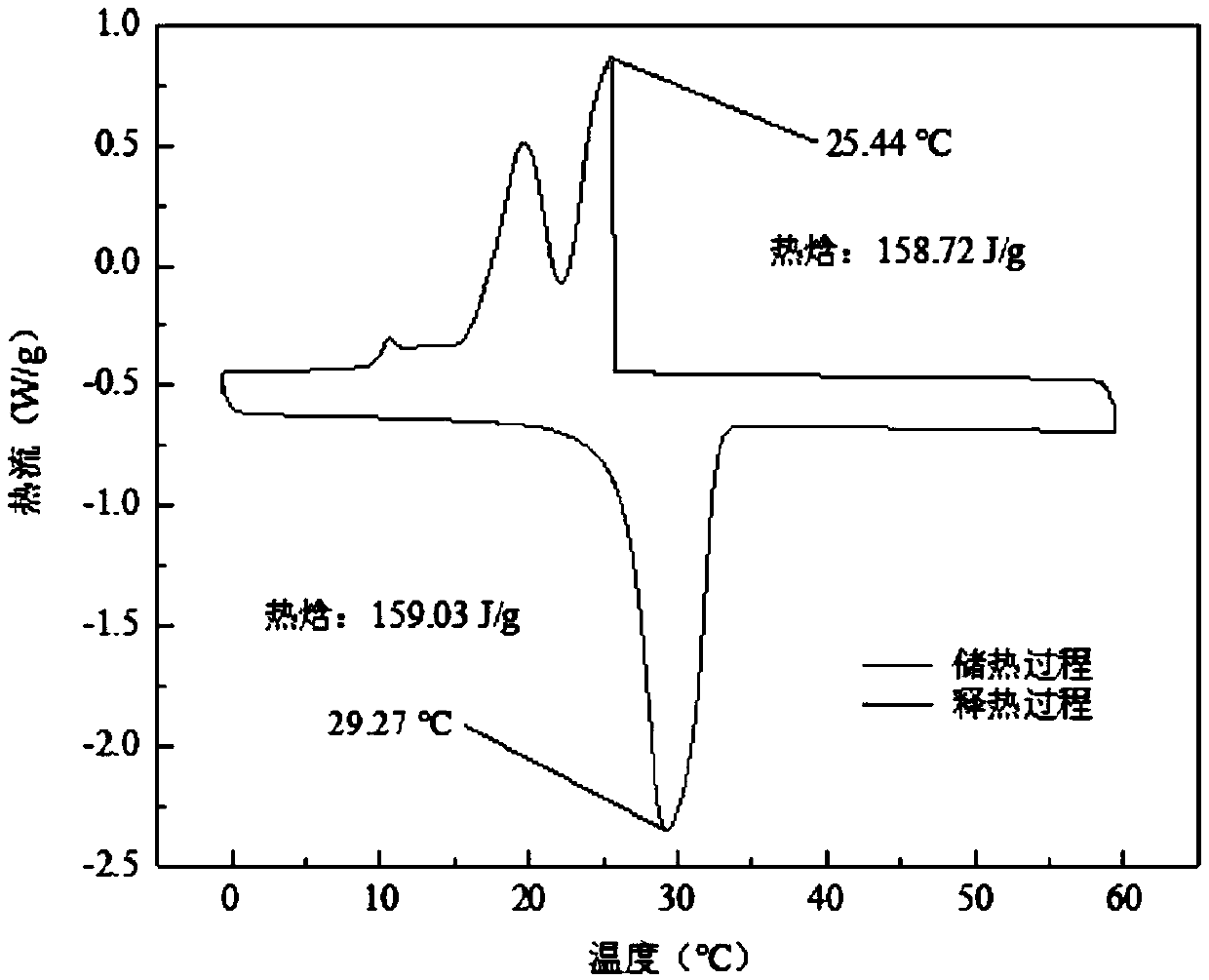

[0051] A phase-change microcapsule with both magnetic properties and light-to-heat conversion properties, comprising a wall material and a core material wrapped in the wall material, the core material comprising n-octadecane and oleic acid-coated ferric iron tetroxide nanoparticles , the wall material includes melamine formaldehyde resin and graphene oxide, and the mass ratio of the core material to the wall material is 1:1.05.

[0052] Its preparation method is the same as that of Example 1, except that the added amount of ferric oxide coated with oleic acid is 0.6 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com