A kind of preparation method of nano platinum titanium electrode

A technology of titanium electrodes and nano-platinum, which is applied in the field of preparation of nano-platinum titanium electrodes, can solve the problems of insufficient bonding between nano-platinum and electrode substrates, high requirements for preparation conditions, and complex preparation systems, and achieve high adsorption capacity of platinum nanometers , The structure of the system is simple and the combination is firm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

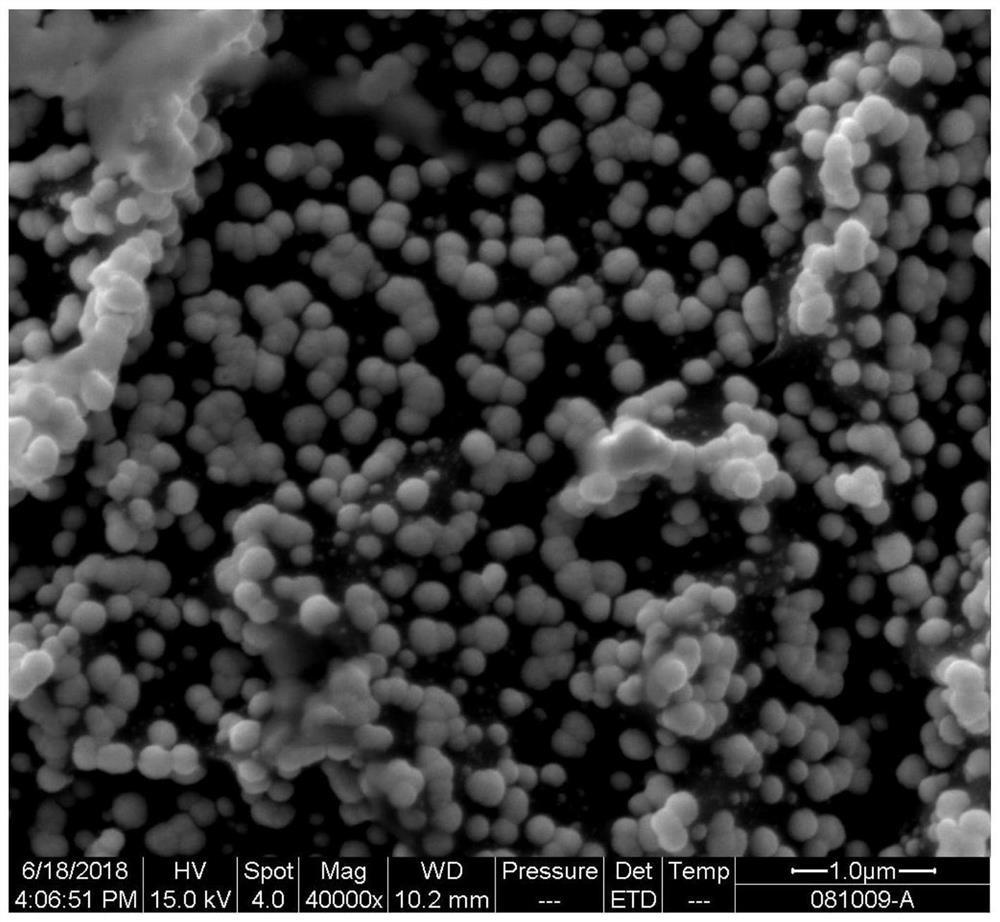

Embodiment 1

[0023] (1) preparation concentration is the potassium hexachloroplatinate solution of 0.02mM;

[0024] (2) Mechanically polish the pure titanium electrode substrate with metallographic sandpaper, immerse it in boiling ethanol for 10 minutes after polishing, take it out and rinse it with water, and wash it in warm 7:3 (v / v) NH 3 / H 2 o 2 Immerse in the aqueous solution for 10 minutes, then rinse the substrate in pure water three times for 2 minutes each time, and dry in the air;

[0025] (3) Use the pure titanium electrode substrate treated in step (2) as the anode, and the graphite rod as the cathode, immerse in the potassium hexachloroplatinate solution prepared in step (1), apply a microvoltage of 15mV, and let it stand for 20min ;

[0026] (4) Add reducing agent ascorbic acid in solution, make ascorbic acid concentration be 0.04M, keep system reaction time 2 hours;

[0027] (5) The obtained nano-platinum-titanium electrode was placed in a muffle furnace, the heat treatm...

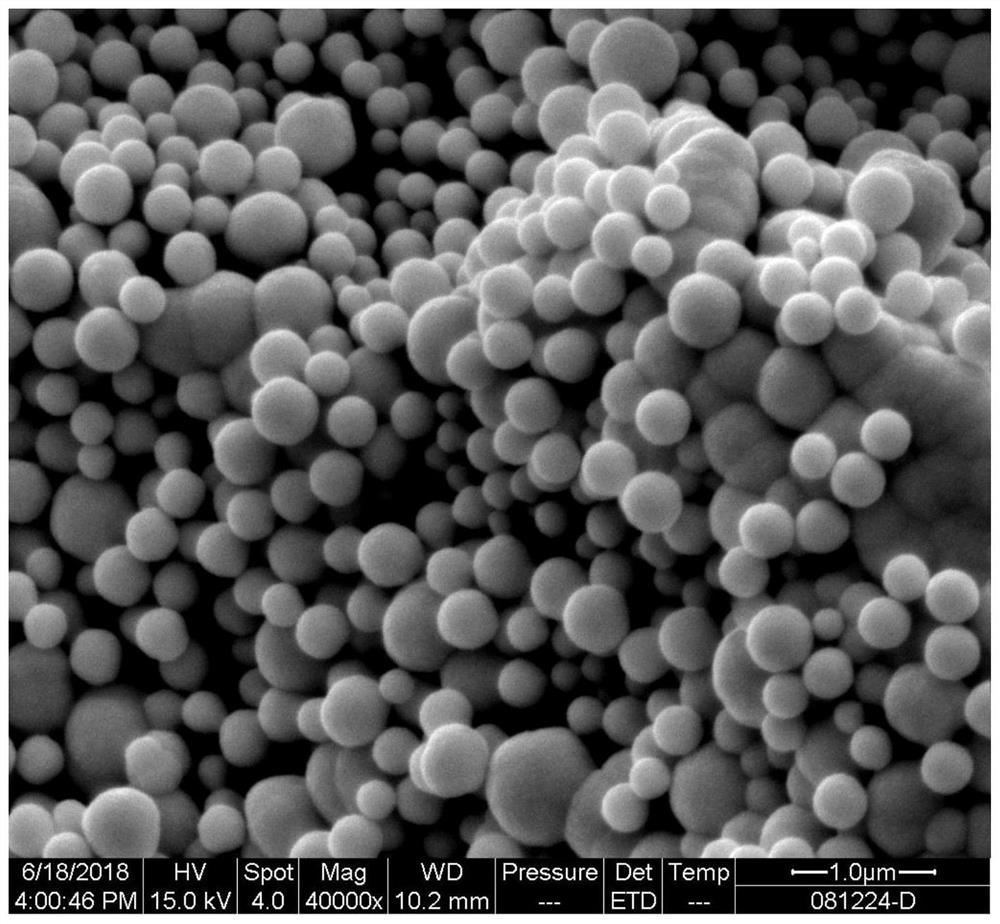

Embodiment 2

[0030] (1) preparation concentration is the potassium hexachloroplatinate solution of 0.06mM;

[0031] (2) Mechanically polish the pure titanium electrode substrate with metallographic sandpaper, immerse it in boiling ethanol for 10 minutes after polishing, take it out and rinse it with water, and wash it in warm 7:3 (v / v) NH 3 / H 2 o 2 Immerse in the aqueous solution for 10 minutes, then rinse the substrate in pure water three times for 2 minutes each time, and dry in a nitrogen stream;

[0032] (3) Use the pure titanium electrode substrate treated in step (2) as the anode, and the graphite rod as the cathode, immerse in the potassium hexachloroplatinate solution prepared in step (1), apply a microvoltage of 40mV, and let it stand for 30min ;

[0033] (4) Add reducing agent ascorbic acid in solution, make ascorbic acid concentration be 0.12M, keep system reaction time 4.5 hours;

[0034] (5) The obtained nano-platinum-titanium electrode was placed in a muffle furnace, the...

Embodiment 3

[0037] (1) preparation concentration is the sodium hexachloroplatinate solution of 0.01mM;

[0038] (2) Mechanically polish the pure titanium electrode substrate with metallographic sandpaper, immerse it in boiling ethanol for 5 minutes after polishing, take it out and rinse it with water, and wash it in warm 7:3 (v / v) NH 3 / H 2 o 2 Immerse in the aqueous solution for 15 minutes, then rinse the substrate in pure water three times for 2 minutes each time, and dry in a nitrogen stream;

[0039] (3) Use the pure titanium electrode substrate that has been surface-treated in step (2) as the anode, and the graphite rod as the cathode, immerse in the sodium hexachloroplatinate solution prepared in step (1), apply a microvoltage of 10mV, and let it stand for 30min ;

[0040] (4) Add reducing agent citric acid in solution, make citric acid concentration be 0.02M, keep system reaction time 1 hour;

[0041] (5) The obtained nano-platinum-titanium electrode was placed in a muffle furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com