Preparation method of nickel-cobalt-phosphorus-carbon-nickel hydroxide ternary composite electrode material

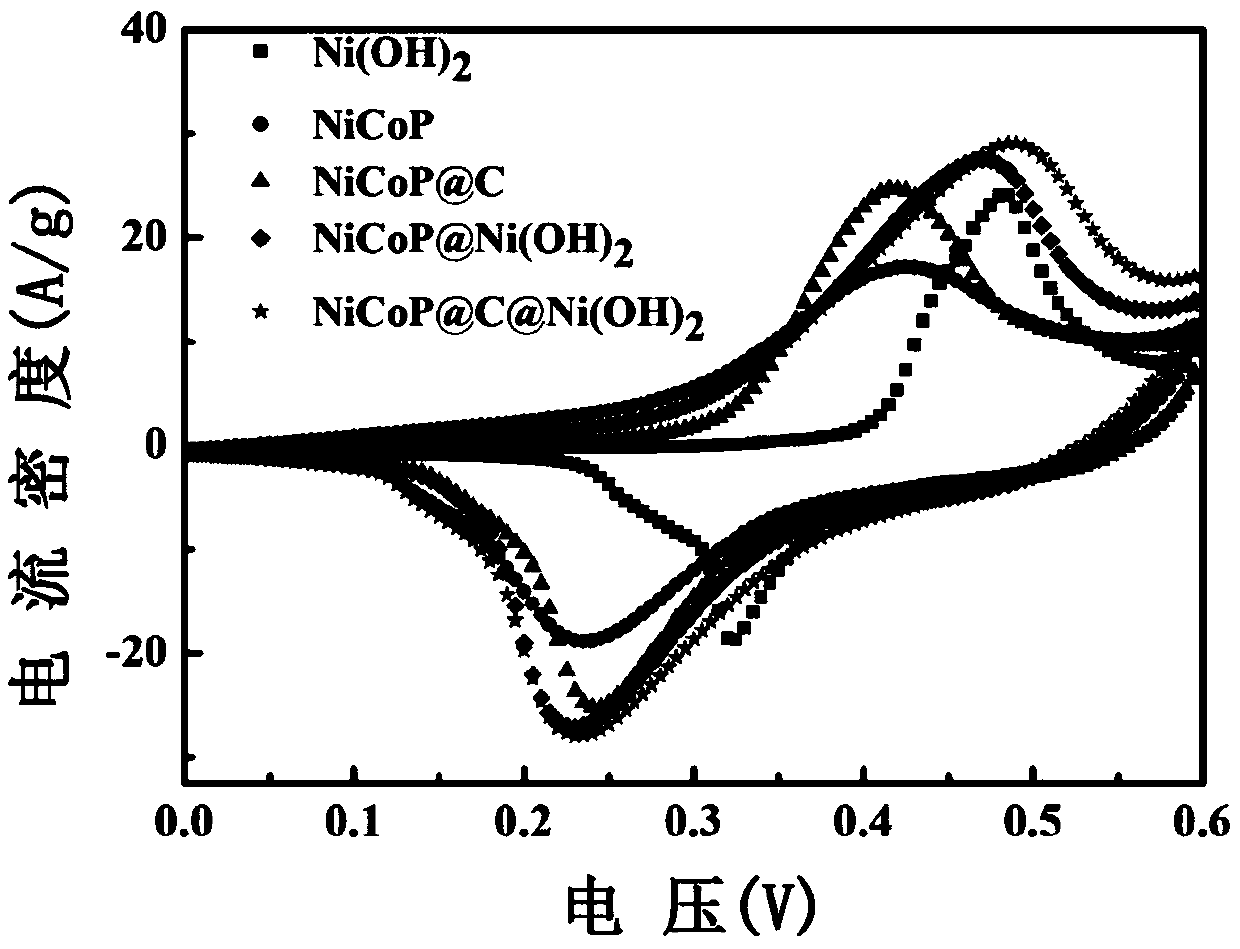

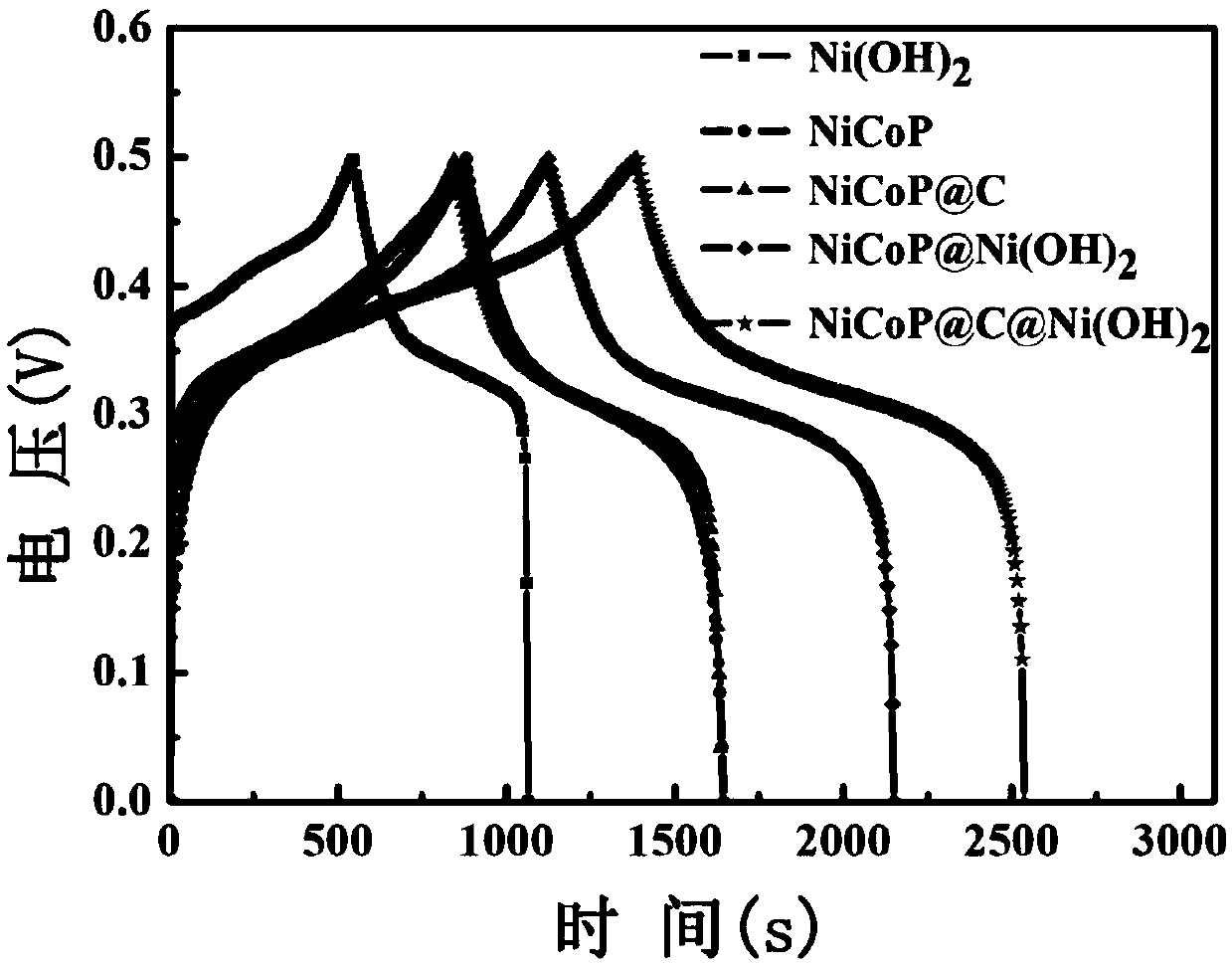

A technology of nickel hydroxide and ternary compounding, which is applied in the field of nanocomposite materials science, can solve the problems of unsatisfactory cycle performance of nickel-cobalt phosphide, and achieve the effects of shortening ion transmission distance, improving specific capacitance and good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Get 1 mmol of nickel nitrate hexahydrate, 2 mmol of cobalt nitrate hexahydrate, 6 mmol of ammonium fluoride, and 15 mmol of urea to be dissolved in 70 ml of deionized water, fully stir for 30 minutes and transfer to 100ml polytetrafluoroethylene reactor. Next, the pretreated nickel foam with a mass of 0.6010 g was put into the reactor, and the reactor was moved to a blast drying oven, and reacted at a constant temperature at 120° C. for 3 hours. After the reaction kettle was cooled to room temperature, the foamed nickel was taken out, rinsed with deionized water and absolute ethanol respectively, and finally placed in a vacuum oven at 60°C for 12 hours to obtain the foamed nickel supporting the nickel-cobalt wire nanoarray matrix;

[0033] (2) Soak the nickel foam loaded with the nickel-cobalt wire nanoarray matrix in step (1) in 100ml of 0.05 mol / liter glucose solution, bathe in water at 80°C for 6h, and place the nickel foam on corundum after taking it out In cru...

Embodiment 2

[0038](1) Get 1 mmol of nickel nitrate hexahydrate, 2 mmol of cobalt nitrate hexahydrate, 6 mmol of ammonium fluoride, and 15 mmol of urea to be dissolved in 70 ml of deionized water, fully stir for 30 minutes and transfer to 100ml polytetrafluoroethylene reactor. Next, the pretreated nickel foam with a mass of 0.6000 g was put into the reactor, and the reactor was moved to a blast drying oven, and reacted at a constant temperature at 120° C. for 3 hours. After the reactor was cooled to room temperature, the nickel foam was taken out, rinsed with deionized water and absolute ethanol, and finally dried in a vacuum oven at 60°C for 12 hours. The nickel foam loaded with the nickel-cobalt wire nano-array matrix is obtained.

[0039] (2) Soak the nickel foam loaded with the nickel-cobalt wire nanoarray matrix in step (1) in 100ml of 0.05 mol / liter glucose solution, bathe in water at 80°C for 6h, and place the nickel foam in a corundum crucible after taking it out In A, move the...

Embodiment 3

[0044] (1) Get 1 mmol of nickel nitrate hexahydrate, 2 mmol of cobalt nitrate hexahydrate, 6 mmol of ammonium fluoride, and 15 mmol of urea to be dissolved in 70 ml of deionized water, fully stir for 30 minutes and transfer to 100ml polytetrafluoroethylene reactor. Next, the pretreated nickel foam with a mass of 0.6001 g was put into the reactor, and the reactor was moved to a blast drying oven, and the reaction was performed at a constant temperature of 120° C. for 3 hours. After the reactor was cooled to room temperature, the nickel foam was taken out, rinsed with deionized water and absolute ethanol, and finally dried in a vacuum oven at 60°C for 12 hours. A nickel foam loaded with a nickel-cobalt wire nanoarray matrix is obtained.

[0045] (2) Soak the nickel foam loaded with the nickel-cobalt wire nanoarray matrix in step (1) in 100ml of 0.05 mol / liter glucose solution, bathe in water at 80°C for 6h, and place the nickel foam in a corundum crucible after taking it out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com