Wet oxidation catalyst for treating oil refining alkaline residue as well as preparation method and application thereof

A technology for wet oxidation and oil refining alkali residues, which is applied in catalyst activation/preparation, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc. It can solve the problems of easy decomposition of carriers and improve catalytic performance , improved diffusion, high catalytic activity and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

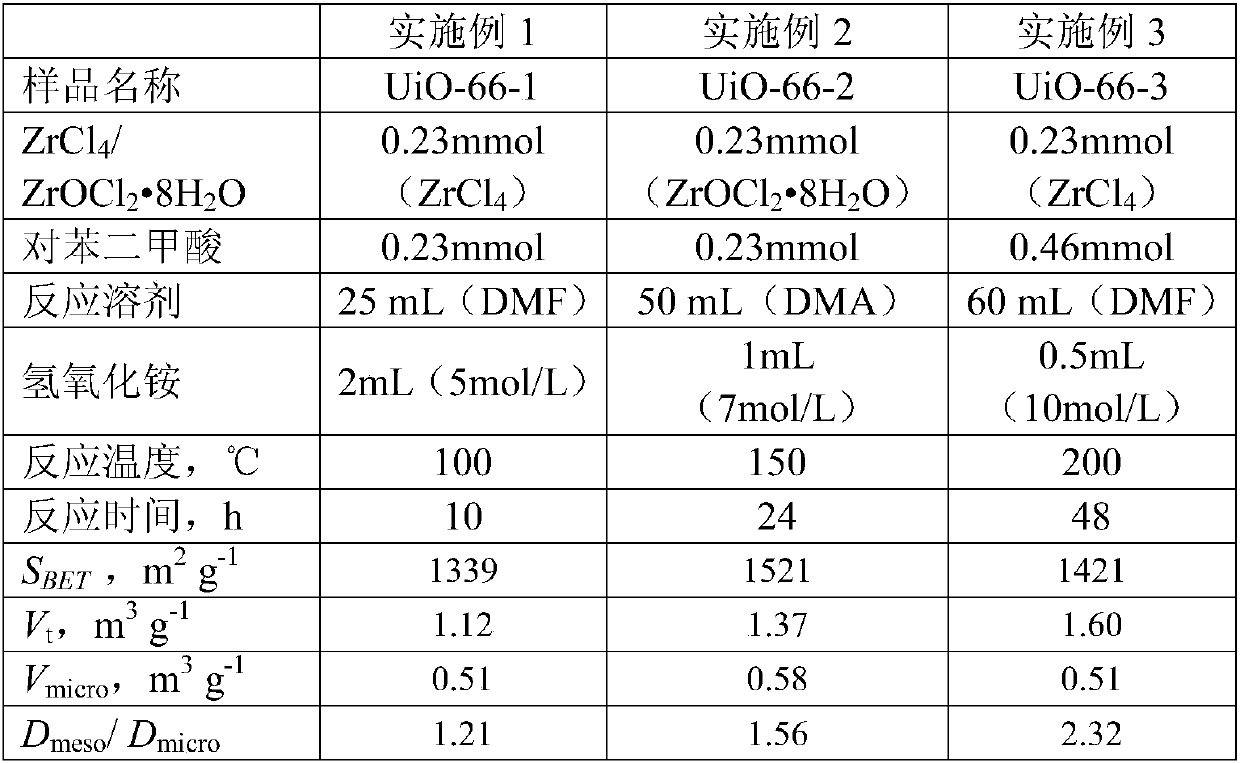

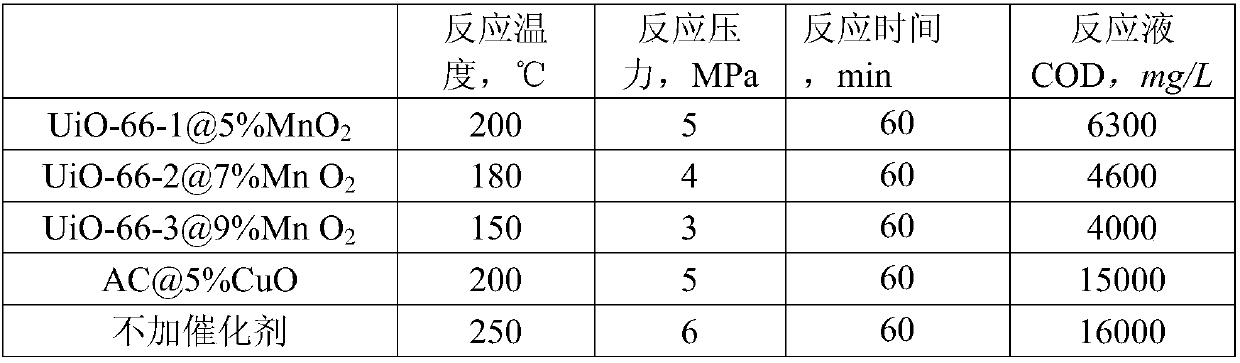

[0028] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

[0029] In each example, the preparation method of the wet oxidation catalyst for processing oil refinery soda residue: comprises the following steps connected in sequence:

[0030] A, metal zirconium salt and terephthalic acid are added in aprotic polar solvent, stirred at room temperature until transparent;

[0031] B. Add alkaline solution to the material obtained in step A, and stir at room temperature until transparent;

[0032] C. Move the material obtained in step B to a reaction kettle with a polytetrafluoroethylene liner, seal the reaction kettle, control the reaction temperature to 50-250° C., and the reaction time to be 10-30 hours; after the reaction is completed, the temperature drops to room temperature, The solid material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com