Glue for battery pole piece surface treatment and preparation process thereof

A surface treatment, battery pole piece technology, applied in the direction of adhesives, graft polymer adhesives, adhesive types, etc., can solve the problems of unfavorable large-scale production, a lot of labor, high cost, and improve the bonding ability and Toughness, anti-cracking effect, increasing hydrophilicity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

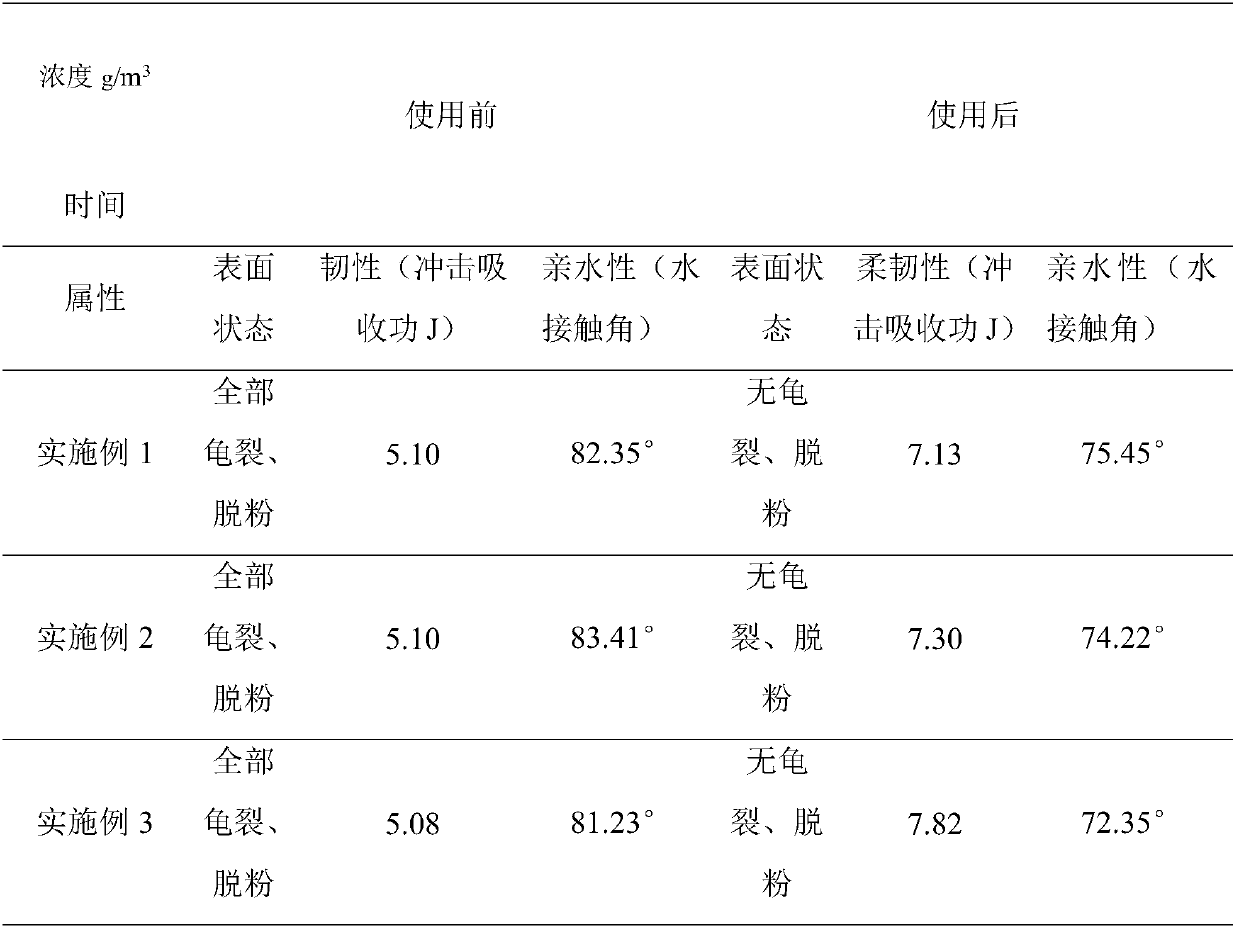

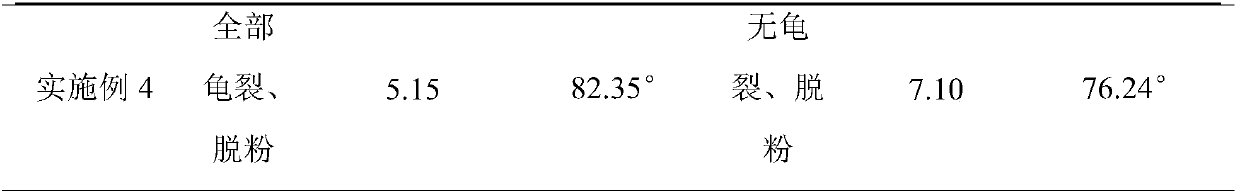

Examples

Embodiment 1

[0022] (1) Raw materials: 1 part of sodium carboxymethyl cellulose, 1 part of polyvinyl alcohol, 3 parts of acrylic acid vinyl alcohol copolymer, 1 part of short fiber and 994 parts of water.

[0023] (2) Preparation method: 1) Take the pre-prepared 10% aqueous solution of polyvinyl alcohol and monomer acrylic acid and mix them in a ratio of 1:6 according to the ratio of polyvinyl alcohol and acrylic acid reaction substance, add a certain amount of initiator, Cross-linking agent (initiator is potassium persulfate, cross-linking agent is a trifunctional aziridine cross-linking agent), after mixing evenly, pass nitrogen gas to remove oxygen for 5 minutes, seal the reaction bottle and place it in a water bath at 70°C to 80°C for 5 hours. Take out the sample, soak it with deionized water for 48 hours, change the water regularly to remove uncrosslinked monomers or polymers, finally cut the gel into thin slices, dry it in the air at room temperature, dry it in vacuum to constant weig...

Embodiment 2

[0029] (1) Raw materials: 10 parts of sodium carboxymethyl cellulose, 20 parts of polyvinyl alcohol, 15 parts of acrylic acid vinyl alcohol copolymer, 6 parts of short fiber and 949 parts of water.

[0030] (2) Preparation method: 1) Take the pre-prepared 10% aqueous solution of polyvinyl alcohol and monomer acrylic acid and mix them in a ratio of 1:6 according to the ratio of polyvinyl alcohol and acrylic acid reaction substance, add a certain amount of initiator, Cross-linking agent (initiator is potassium persulfate, cross-linking agent is a trifunctional aziridine cross-linking agent), after mixing evenly, pass nitrogen gas to remove oxygen for 5 minutes, seal the reaction bottle and place it in a water bath at 70°C to 80°C for 5 hours. Take out the sample, soak it with deionized water for 48 hours, change the water regularly to remove uncrosslinked monomers or polymers, finally cut the gel into thin slices, dry it in the air at room temperature, dry it in vacuum to constan...

Embodiment 3

[0036] (1) Raw materials: 6 parts of sodium carboxymethyl cellulose, 30 parts of polyvinyl alcohol, 18 parts of acrylic acid vinyl alcohol copolymer, 4 parts of short fiber and 942 parts of water.

[0037] (2) Preparation method: 1) Take the pre-prepared 10% aqueous solution of polyvinyl alcohol and monomer acrylic acid and mix them in a ratio of 1:6 according to the ratio of polyvinyl alcohol and acrylic acid reaction substance, add a certain amount of initiator, Cross-linking agent (initiator is potassium persulfate, cross-linking agent is a trifunctional aziridine cross-linking agent), after mixing evenly, pass nitrogen gas to remove oxygen for 5 minutes, seal the reaction bottle and place it in a water bath at 70°C to 80°C for 5 hours. Take out the sample, soak it with deionized water for 48 hours, change the water regularly to remove uncrosslinked monomers or polymers, finally cut the gel into thin slices, dry it in the air at room temperature, dry it in vacuum to constant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com