Nickel base alloy, preparation method of nickel base alloy and manufactured goods

A technology for nickel-based alloys and articles, applied in mechanical equipment, engine components, machines/engines, etc., and can solve problems such as low high temperature creep strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

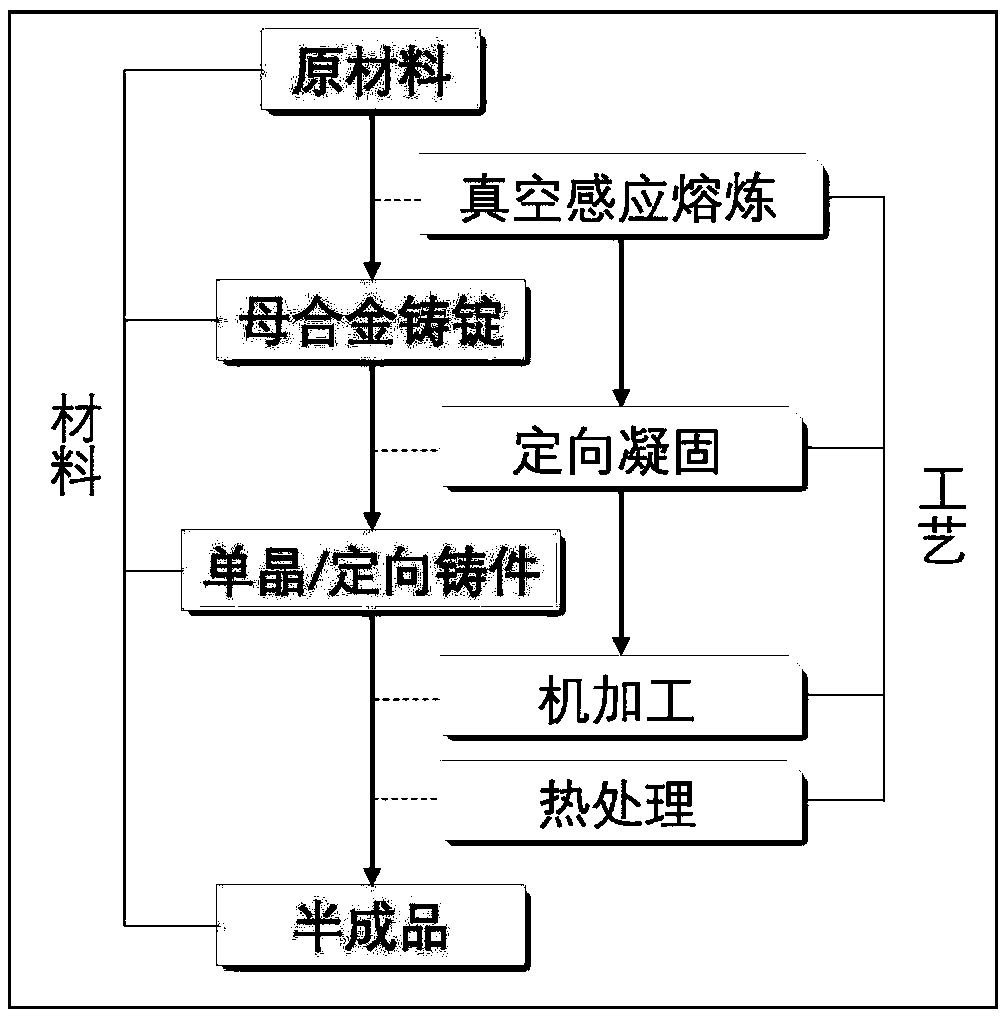

[0076] The application also provides a method for preparing a nickel-based alloy, comprising the following steps:

[0077] A) preparing nickel-based master alloy ingot according to the composition ratio of the above-mentioned nickel-based alloy;

[0078] B) remelting the nickel-based master alloy ingot, and then preparing nickel-based alloy castings;

[0079] C) performing heat treatment on the nickel-based alloy casting to obtain a nickel-based alloy.

[0080] In the above nickel-based alloy preparation method, the specific composition of the nickel-based master alloy ingot has been described in detail above, and will not be repeated here.

[0081] In the above-mentioned process of preparing nickel-based alloys, the method for preparing nickel-based master alloy ingots is carried out according to methods well known to those skilled in the art. For example, the present application puts the raw materials into a vacuum melting furnace for melting according to the composition ra...

Embodiment

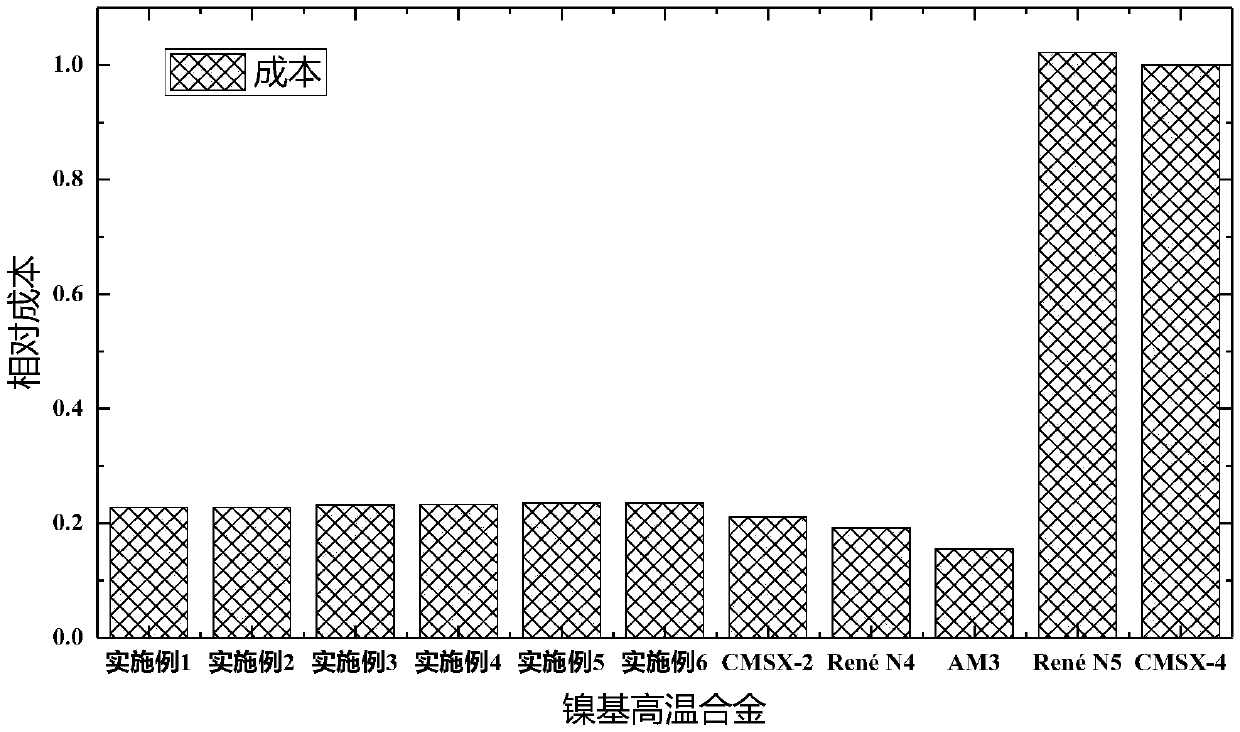

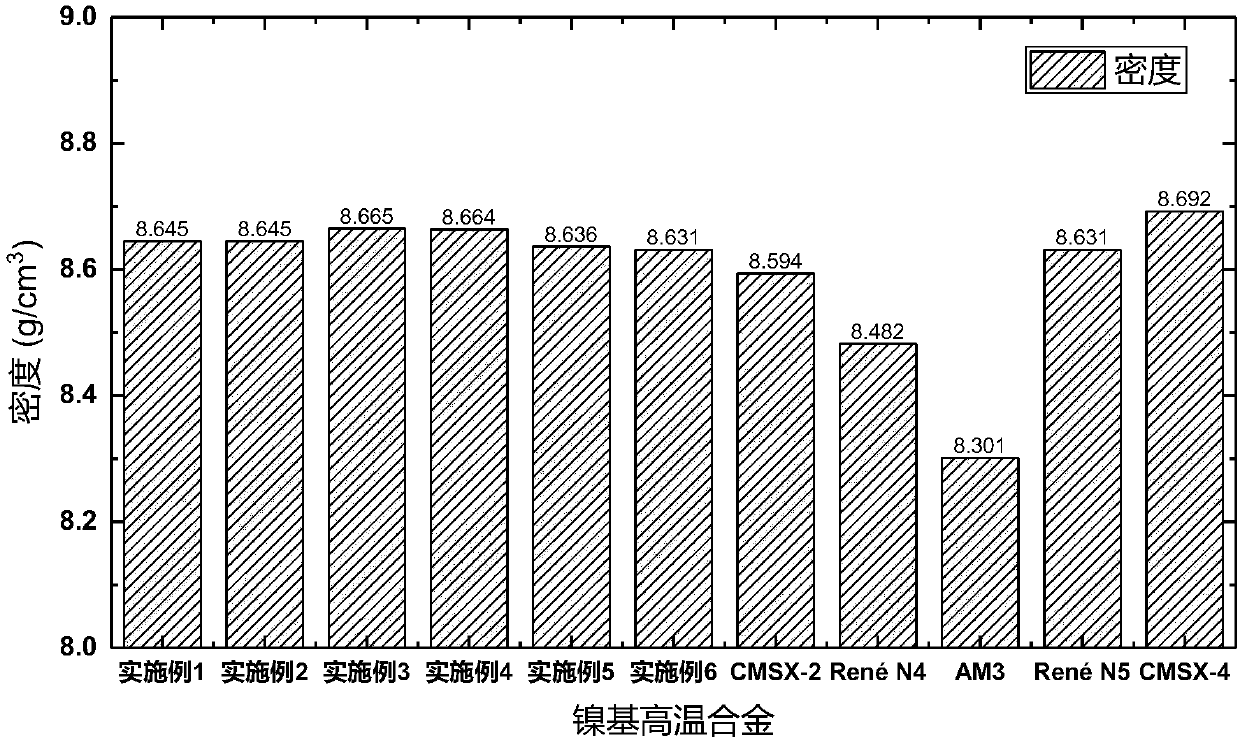

[0092] The nickel-based high-temperature alloy of the present application achieves a good balance in terms of alloy density, alloy cost, structure stability, high-temperature strength, etc., and has excellent comprehensive performance. In order to further illustrate the effect of the present application, the present application lists 7 specific examples, and compares 6 of them with 5 existing alloys. 7 embodiment alloy composition and 5 kinds of existing alloy composition are as shown in table 1; In embodiment, the preparation method of described nickel-based superalloy is specifically:

[0093] 1) put the raw materials according to the composition ratio shown in Table 1 into a vacuum induction melting furnace to melt the alloy, and prepare a master alloy ingot;

[0094] 2) Remelting the master alloy ingot in a vacuum device, and then preparing a columnar crystal casting by directional solidification in a mold shell formed by a refractory material, or preparing a single crysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com