A Method for Enhancing Wetting Characteristics and Phase-change Thermal Performance of Heat Sink

A technology of wetting characteristics and phase transformation heat, which is applied in chemical instruments and methods, cleaning methods and utensils, cooling/ventilation/heating transformation, etc. It can solve problems such as unfavorable assembly line operation, unsatisfactory cleaning effect, and cumbersome operation steps. , to achieve the effect of improving the strengthening effect, fast processing speed and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

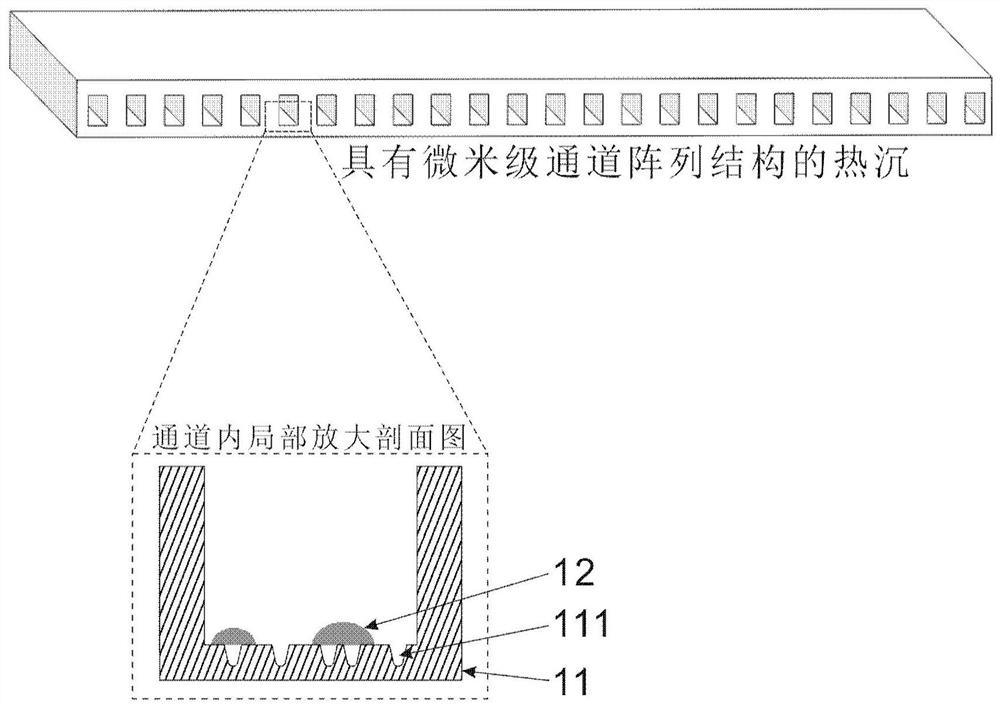

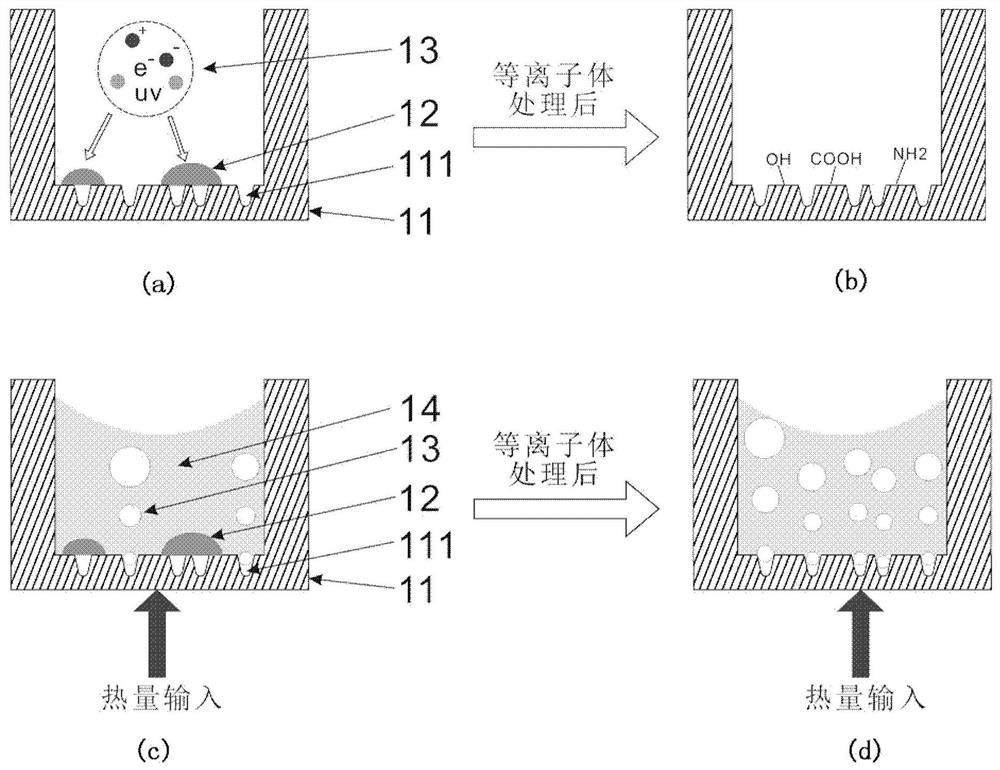

[0041] Such as figure 2 As shown, the heat sink has a micro-nano structure surface, and after constructing a channel array with dimensions (including channel width, height and channel spacing) preferably between 0.01-0.9 mm on the flat heat sink, a micron-scale channel array structure can be formed heat sink, referred to as microchannel heat sink 11. When the heat load of the heat-generating device is input, the heat sink of this structure can undergo micro-scale phase transformation heat, and realize the heat dissipation process of high heat transfer coefficient and heat flux density. However, in the process of mechanical processing and daily storage, there will be more grease and oil residue inside the microchannel, such as figure 2 The partially enlarged schematic diagram of the internal cross-section of the channel is shown. Grease and oil stains 12 cover the inner surface of the heat sink micro-channel. Due to its own hydrophobic characteristics and blockage of the mi...

Embodiment 2

[0052] Such as Figure 4 As shown, the heat sink has a flat surface, and the plasma treatment can clean the grease and oil on the surface of the heat sink in batches and perform functional modification on the surface, so as to obtain a heat sink with excellent wetting characteristics and phase transfer heat performance on a large scale , so as to facilitate the industrial production of high-performance radiators. Initially clean the surfaces of multiple heat sinks to remove dust or solid particle impurities that may be contained on the heat sink surfaces. Then place multiple heat sinks that have been preliminarily cleaned in the processing chamber, select one or more of argon, nitrogen, and oxygen as the process gas, and generate corresponding single-component plasma or mixed plasma to process the heat sink . Layered trays are arranged inside the plasma processing chamber, which is convenient for placing multiple heat sinks in the chamber, so that they are evenly distributed...

Embodiment 3

[0054] Such as Figure 5 As shown, spin-coating graphene solution on copper plate 31 and drying will add a layer of porous graphene nano-coating 32, and the coating thickness is preferably between 1-10000nm, forming a kind of heat with nano-coating on the surface. Shen, there may be some grease and oil on the surface of the heat sink 33, the surface of the nanostructure heat sink is initially cleaned, and after removing the dust or solid particle impurities that may be contained on the surface, one or more of argon, nitrogen, and oxygen are selected. As a process gas, the corresponding single-component plasma or mixed plasma is generated to treat the nanostructure heat sink, which can fully clean the grease and oil on the surface of the heat sink and perform functional modification on the surface to enhance the wetting characteristics and phase transition. heat transfer performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com