Low-temperature halogen-free lead-free soldering paste and preparation method thereof

A halogen-free lead-free solder paste and low-temperature technology, applied in the field of low-temperature halogen-free lead-free solder paste and its preparation, can solve the problems of lowering insulation resistance, lowering reliability, corroding substrates, etc., improving wettability and prolonging storage life. and service life, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

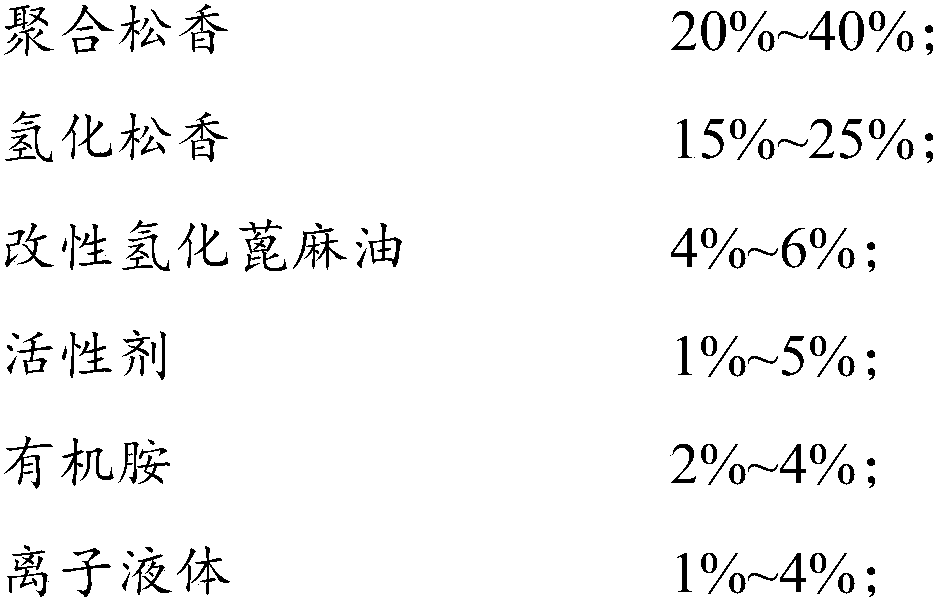

[0025] Flux preparation raw materials include: polymerized rosin 24g, hydrogenated rosin 20g, modified hydrogenated castor oil 6g, adipic acid 4g, salicylic acid amide 1g, triisoethanolamine 1.3g, polyethylene glycol 22g, ethylene glycol hexyl ether 20g , 1-aminopropyl-3-methylimidazole nitrate 1.7g.

[0026] Preparation method: Mix 24g of polymerized rosin, 20g of hydrogenated rosin, 42g of polyethylene glycol and 20g of ethylene glycol hexyl ether to dissolve together at a temperature of 150°C, then add 6g of modified hydrogenated castor oil, and then add hexylene glycol after completely dissolving Acid 4g, prepared mixture A;

[0027] The mixture A was cooled, and when it was cooled to 80°C, 1g of salicylic acid amide, 1.3g of triisoethanolamine and 1.7g of 1-aminopropyl-3-methylimidazole nitrate were added, and then continued to cool to room temperature to obtain auxiliary flux;

[0028] Mix 12g of flux with 88g of Sn42Bi58 solder alloy powder and vacuum stir evenly to o...

Embodiment 2

[0030] Flux preparation raw materials include: polymerized rosin 40g, hydrogenated rosin 15g, modified hydrogenated castor oil 5g, salicylic acid 2g, triisoethanolamine 2.5g, diethylene glycol monobutyl ether 20g, ethylene glycol hexyl ether 13g, 1- Aminopropyl-3-methylimidazole nitrate 2.5g.

[0031] The preparation method of the flux in this embodiment is the same as that in Embodiment 1, and will not be described in detail here.

[0032] 11 g of flux and 89 g of Sn42Bi58 solder alloy powder were mixed and evenly stirred under vacuum to obtain the solder paste of this embodiment.

Embodiment 3

[0034] Flux preparation raw materials include: polymerized rosin 20g, hydrogenated rosin 25g, modified hydrogenated castor oil 4g, salicylic acid amide 2g, isosuberic acid 4g, diethylene glycol dibutyl ether 10g, polyethylene glycol 20g, ethylene glycol Alcohol hexyl ether 11g, 1-aminoethyl-3-methylimidazole nitrate 4g.

[0035] The preparation method of the solder paste in this embodiment is the same as that in Embodiment 1, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com