Cis-butenedioic acid di-2-ethylhexyl ester, method for synthesizing same and application of cis-butenedioic acid di-2-ethylhexyl ester to preparing polycarboxylic acid water reducing agents

A technology of maleic acid diester and maleic acid monoester, which is applied in the field of chemical synthesis, can solve problems such as poor slump retention performance, and achieve the effects of no safety hazard, good water solubility, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

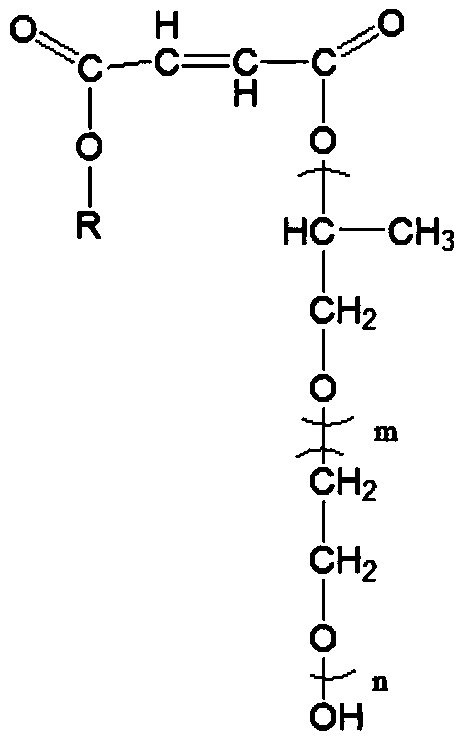

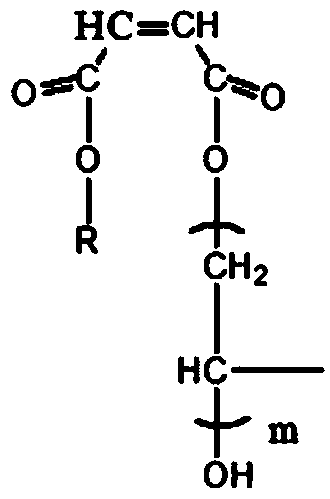

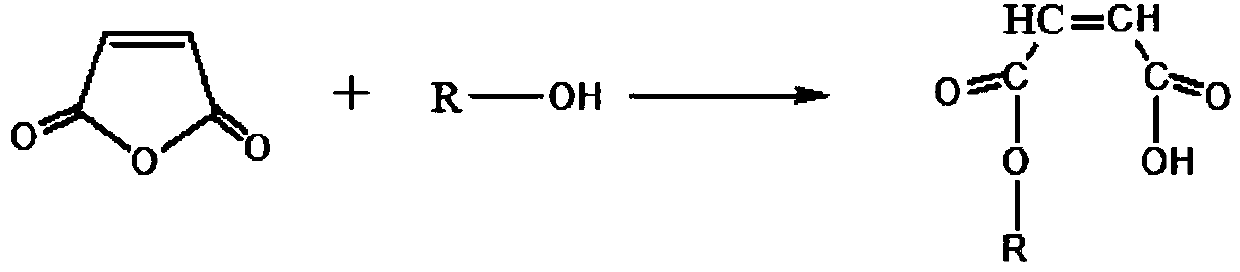

[0036] A kind of synthetic method of maleic acid diester, comprises the following steps:

[0037] (1) Add 1000 parts of maleic anhydride and 469 parts of ethanol into the reaction kettle, raise the temperature to 60°C, stir for 3 hours, then raise the temperature to 90°C for 2 hours, after the reaction is completed, remove the unreacted ethanol by distillation under reduced pressure , to obtain maleic acid monoester;

[0038] (2) The gas in the reaction kettle is replaced with nitrogen by means of spray circulation, circulated for 1 minute, and 600 parts of maleic acid monoesters prepared in step (1) and 2.24 parts of sodium hydroxide are added successively, and nitrogen gas is carried out again. Replace and keep nitrogen circulation, then raise the temperature to 98°C, start adding ethylene oxide, stop when the pressure reaches 0.05mp, continue to add ethylene oxide when the pressure drops to 0.04mp, stop when the pressure reaches 0.1mp, After the pressure drops to 0.08mp, c...

Embodiment 2

[0040] A kind of synthetic method of maleic acid diester, comprises the following steps:

[0041] (1) Add 1000 parts of maleic anhydride and 1224.5 parts of diethylene glycol monomethyl ether into the reaction kettle, raise the temperature to 60°C, stir for 3 hours, then raise the temperature to 90°C for 2 hours, after the reaction is completed, reduce the pressure Distillation removes unreacted diethylene glycol monomethyl ether to obtain maleic acid monoester;

[0042](2) Nitrogen replacement is carried out by means of spray circulation, which is circulated for 1 minute, and 600 parts of maleic acid monoester prepared in step (1) and 4.05 parts of sodium ethoxide are successively added, nitrogen replacement is carried out again, and nitrogen circulation is maintained, Then heat up to 102°C, start adding propylene oxide, stop when the pressure reaches 0.05mp, continue to add propylene oxide when the pressure drops to 0.04mp, stop when the pressure reaches 0.1mp, and continue ...

Embodiment 3

[0044] A kind of synthetic method of maleic acid diester, comprises the following steps:

[0045] (1) Add 1000 parts of maleic anhydride and 612.2 parts of isopropanol into the reactor, raise the temperature to 60°C, stir for 3 hours, then raise the temperature to 90°C for 2 hours, after the reaction is completed, remove unreacted by vacuum distillation The isopropanol, obtain maleic acid monoester;

[0046] (2) Nitrogen replacement is carried out by means of spray circulation, and the circulation is 1 minute, followed by adding 600 parts of maleic acid monoester prepared in step (1) and 5.8 parts of sodium methoxide, nitrogen replacement is carried out again, and nitrogen circulation is maintained, Then heat up to 98°C, start adding propylene oxide, stop when the pressure reaches 0.05mp, continue to add propylene oxide when the pressure drops to 0.04mp, stop when the pressure reaches 0.1mp, and continue adding when the pressure drops to 0.08mp Propylene oxide, stop when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com