Method for measuring hydroxy polybrominated diphenyl ether in plant samples

A hydroxy polybrominated diphenyl ether and sample technology, applied in the detection field, can solve the problems of inaccurate quantitative results, affecting OH-PBDEs, and low selectivity, and achieve the effects of reducing the impact of detection results, improving accuracy and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

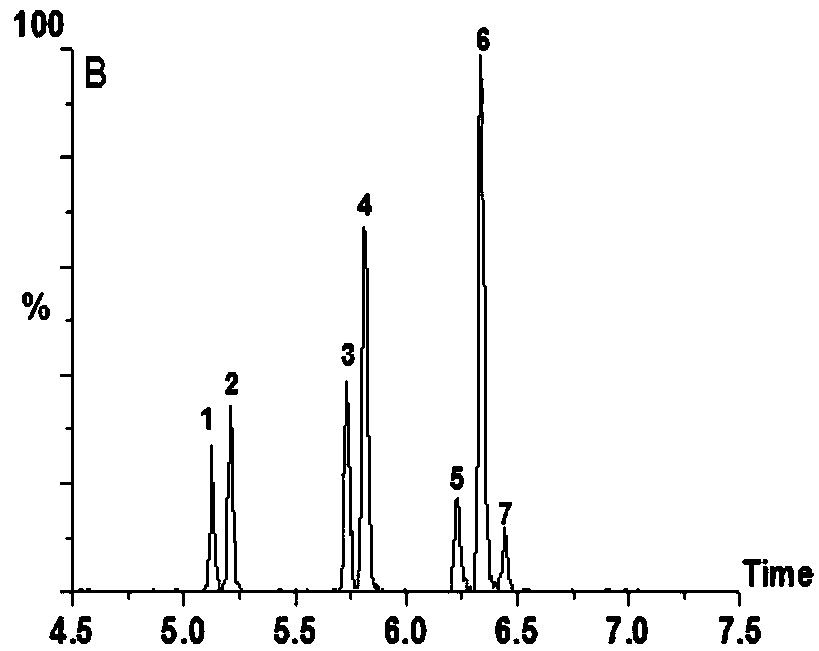

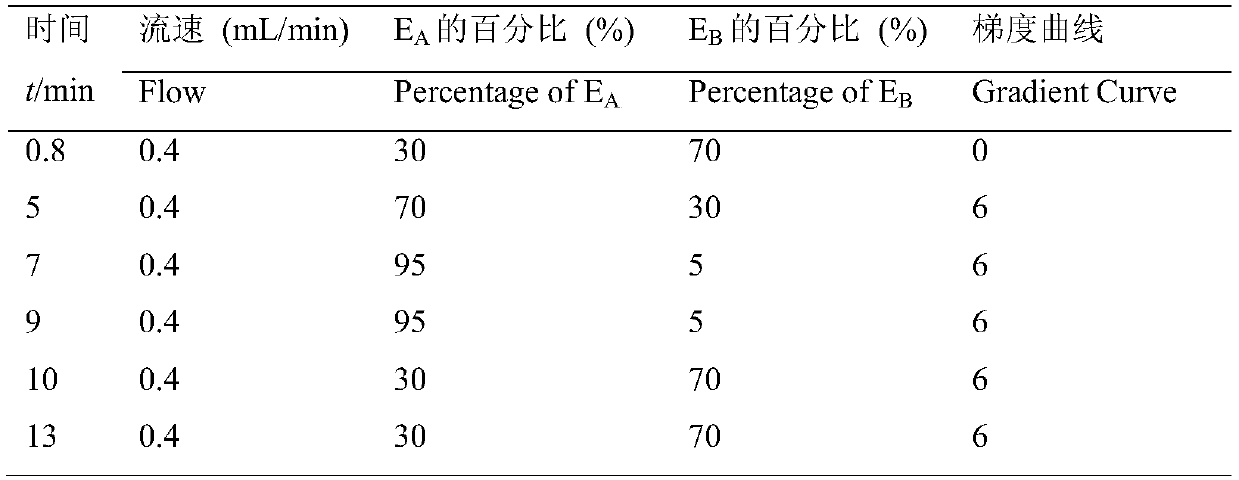

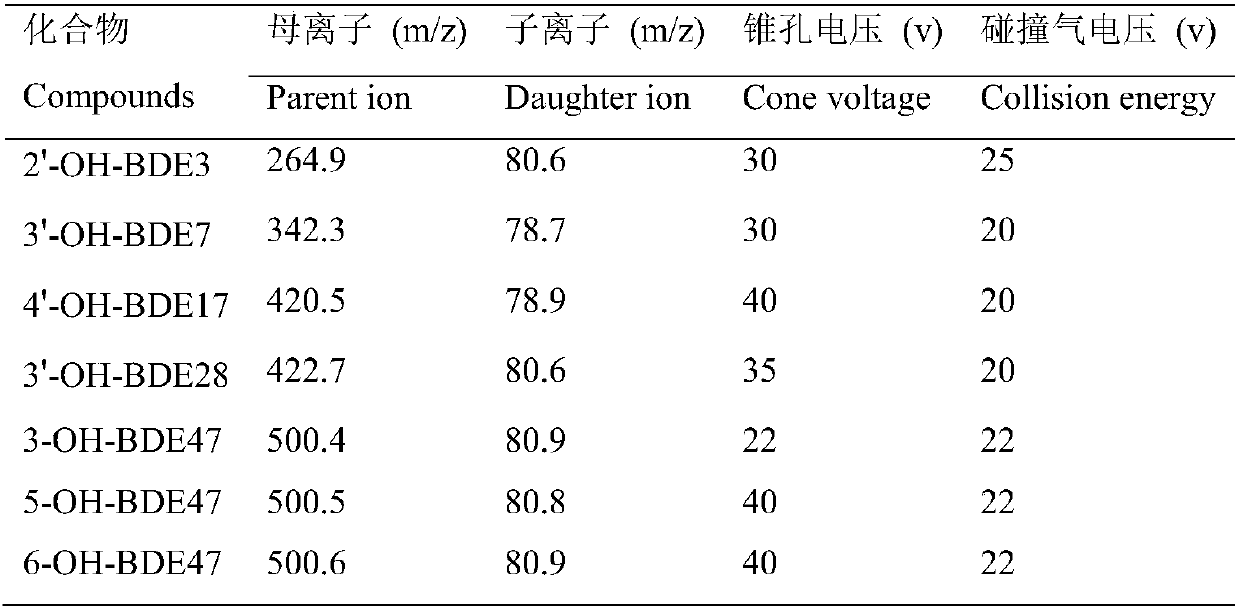

Method used

Image

Examples

preparation example Construction

[0032] Preparation of porous magnetic ferric oxide: under the protection of nitrogen, take 20g of 1.0mmol / g FeSO 4 ·7H 2 O and 40 g FeSO at 2.0 mmol / g 4 ·6H 2 O was added to 1000mL ethylene glycol, stirred until the solid was dissolved, then added 100g of dodecylamine (surfactant), stirred at 300rpm and 25°C for 10min, added 20g of ammonium acetate, continued to stir for 30min, and then continued stirring to add 15g of sodium citrate, stirred at 500rpm until the suspension becomes a uniform solution, put it in a stainless steel reactor, place the reactor in an oven and heat it to 200°C, keep it warm for 10h, then cool down to room temperature, then Centrifuge at a speed of 10000r / min for 5min, wash with ethanol and deionized water, and dry in vacuum at a vacuum degree of -0.06MPa and a temperature of 60°C to obtain porous magnetic ferric oxide;

[0033]Coating: Take 60g of porous magnetic ferric ferric oxide and place it in 1000mL of methanol solution, then add 180g of need...

Embodiment 1

[0039] Extraction: cut the freeze-dried plant sample into pieces, accurately weigh 3.0g (dry weight), add 2mL, 37wt% HCl solution and 10mL isopropanol to mix, then add 3mL n-hexane-MTBE mixed solution A ( The volume ratio of n-hexane to MTBE in n-hexane-MTBE mixed solution A is 1:1), ultrasonically oscillated for 24 hours, centrifuged at a speed of 10000rpm, removed once to extract the organic phase, precipitated and repeated all the above operations, combined twice and once extracted the organic phase phase to obtain the crude extract;

[0040] Secondary extraction: After drying the organic phase in the crude extract with nitrogen, dissolve it in 2 mL of n-hexane, add 1 mL of NaOH solution for extraction (the NaOH solution is obtained by dissolving 0.5 mol / L NaOH in 50% ethanol), and separate to obtain Extract the organic phase and the aqueous phase twice, add 2mL n-hexane to the aqueous phase to extract the aqueous phase again, then add 300μL, 2M HCl solution, and extract th...

Embodiment 2

[0045] Extraction: Cut the freeze-dried plant sample into pieces, accurately weigh 4.0g (dry weight), add 3mL, 37wt% HCl solution and 15mL isopropanol and mix well, then add 4.5mL n-hexane-MTBE mixed solution A (The volume ratio of n-hexane to MTBE in n-hexane-MTBE mixed solution A is 1:1), ultrasonically oscillated for 24 hours, centrifuged at a speed of 10000rpm, removed once to extract the organic phase, precipitated and repeated all the above operations, combined twice and once extracted The organic phase obtains a crude extract;

[0046] Secondary extraction: After the organic phase in the crude extract was blown dry with nitrogen, it was dissolved in 3mL of n-hexane, and 1.5mL of NaOH solution was added for extraction (the NaOH solution was obtained by dissolving 0.5mol / L NaOH in 50% ethanol), and separated To obtain the secondary extraction of the organic phase and the aqueous phase, add 3 mL of n-hexane to the aqueous phase to extract the aqueous phase again, then add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com