Method for preparing grating microarray with color surface by utilizing femtosecond laser, and application

A femtosecond laser and microarray technology, used in laser welding equipment, manufacturing tools, opto-mechanical equipment, etc., can solve the problems of complex preparation process, irregular surface structure, difficult control of preparation process, etc., and achieve low preparation cost and efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Preparation of grating microarray structure by four-beam interference of femtosecond laser

[0026] By building a four-beam interference system and using the periodic light field distribution generated by the interference to expose, develop, and etch the photoresist flat film, a three-dimensional columnar grating microarray structure with a corresponding period can be obtained.

[0027] The method for preparing a grating microarray structure by using femtosecond laser four-beam interference, the specific steps are as follows:

[0028] (1) Build a four-beam laser interference system:

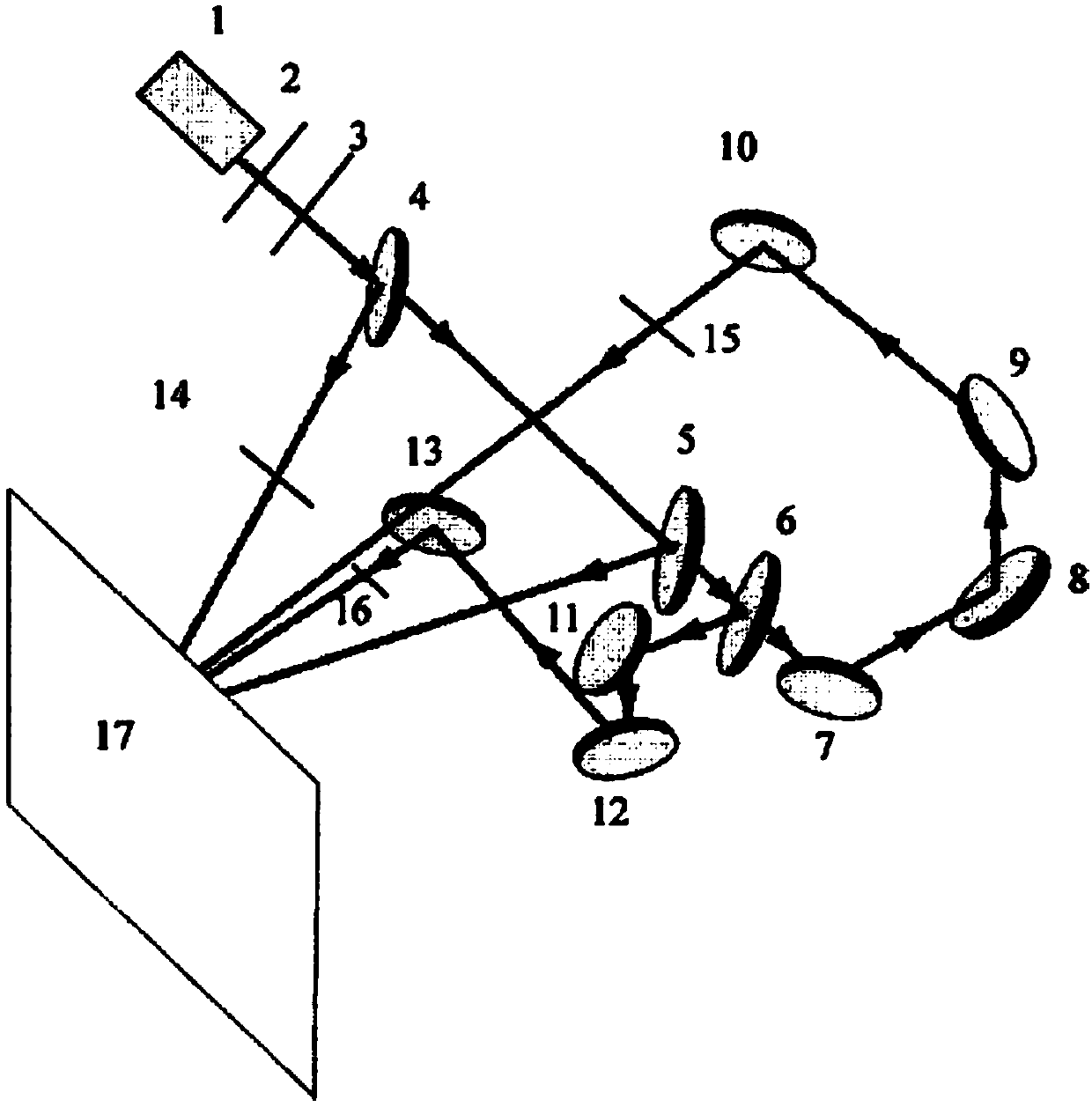

[0029] figure 1 It is a schematic diagram of the optical path of four-beam laser interference. The laser used is frequency-tripled, mode-locked, neodymium-doped yttrium aluminum garnet single-mode laser (Lab-Series) provided by American Spectrum Corporation. The four-beam coherent laser generation process is as follows:

[0030] First, the laser beam emitted by the laser 1 wi...

Embodiment 2

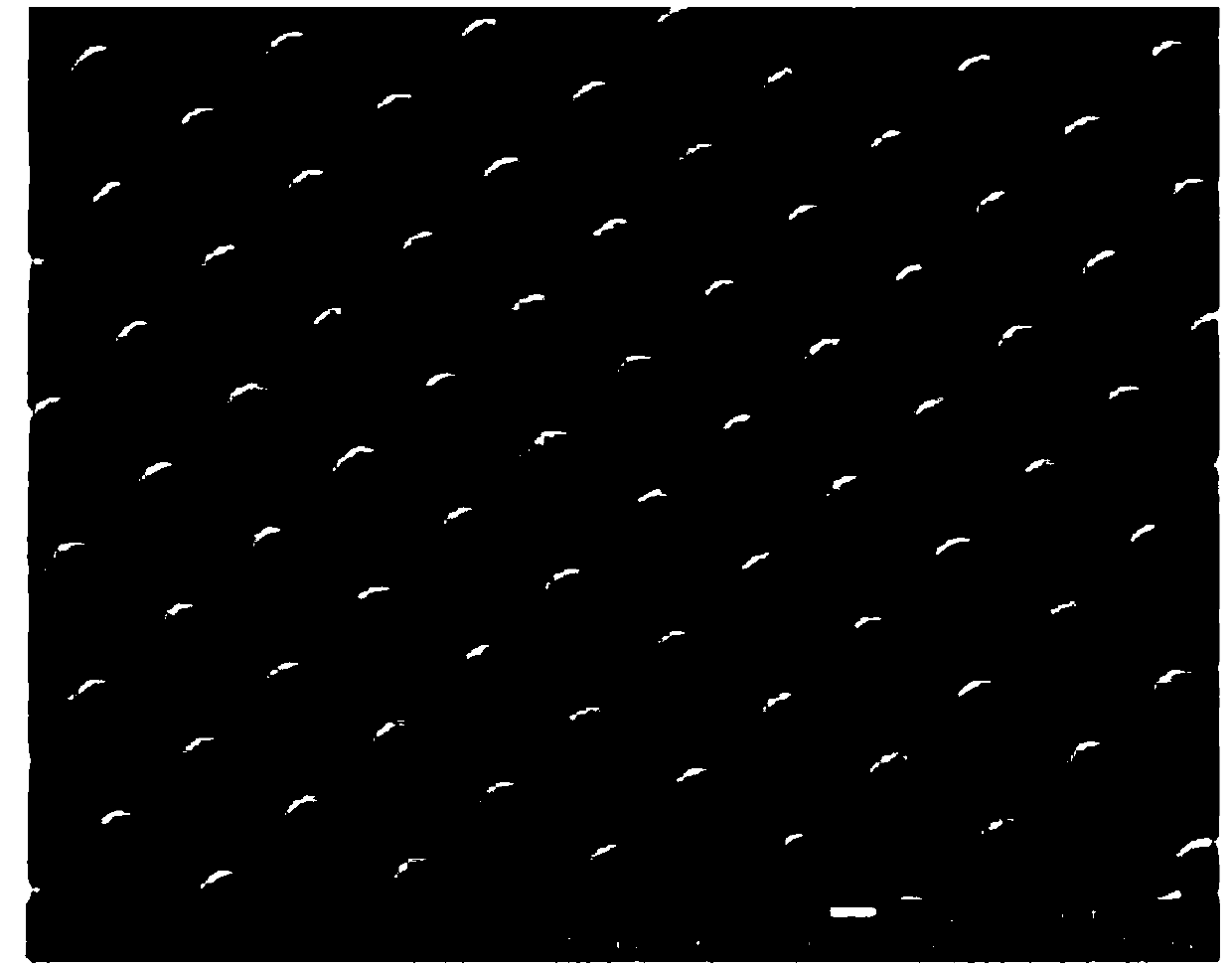

[0036] Embodiment 2 Utilizes superhydrophobic grating microarray structure to produce colored surface

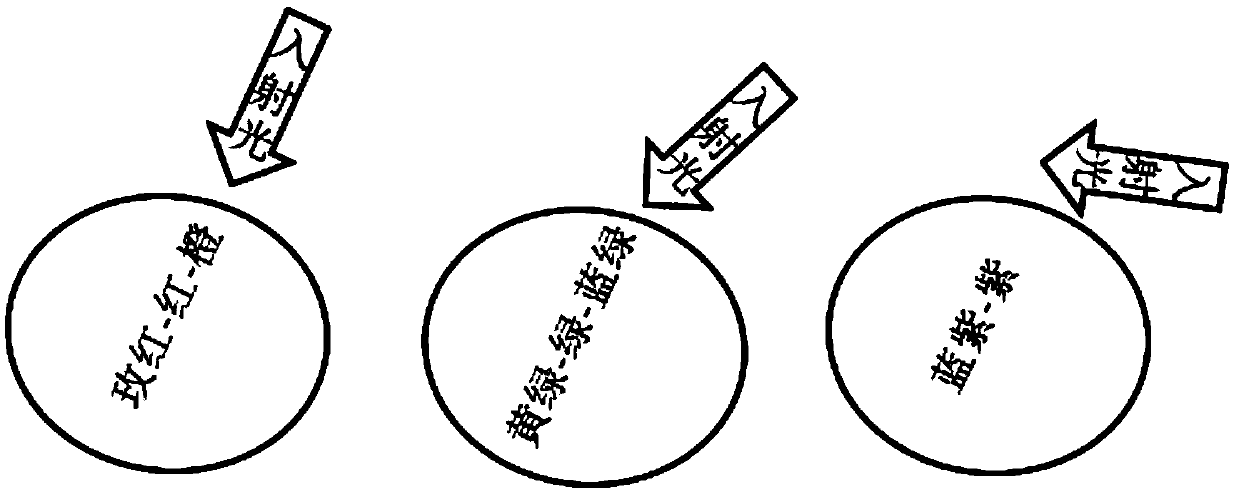

[0037] The grating microstructure array prepared by femtosecond laser has micro-nano scale periodicity, which can diffract the incident light to produce rich colors, that is, bionic structural color. At the same time, the surface modification of the grating microstructure array enables it to obtain super-hydrophobic surface properties, that is, the structure realizes two bionic properties at the same time.

[0038] The method for producing a colored surface using a superhydrophobic grating microarray structure, the specific steps are as follows:

[0039] Preparation steps (1), (2), (3) are the same as in Example 1

[0040] (4) Modification of low surface energy materials: using thermal evaporation, the low surface energy paraffin is evaporated into gas, and the carbon material used is carbon nanoparticles, so that it is adsorbed on the surface of the grating microarray prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com