Smoke wet desulfurizing and denitrifying wastewater resource treatment system and method

A wet desulfurization, desulfurization and denitrification technology, applied in gaseous effluent wastewater treatment, chemical instruments and methods, water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment is applied to the treatment of flue gas from industrial kilns in ceramic factories and the resource treatment of desulfurization and denitrification wastewater. Among them, the industrial kiln flue gas particles in ceramic factories, SO 2 , NOx initial emission concentration is 58mg / m 3 、162mg / m 3 , 135mg / m 3 .

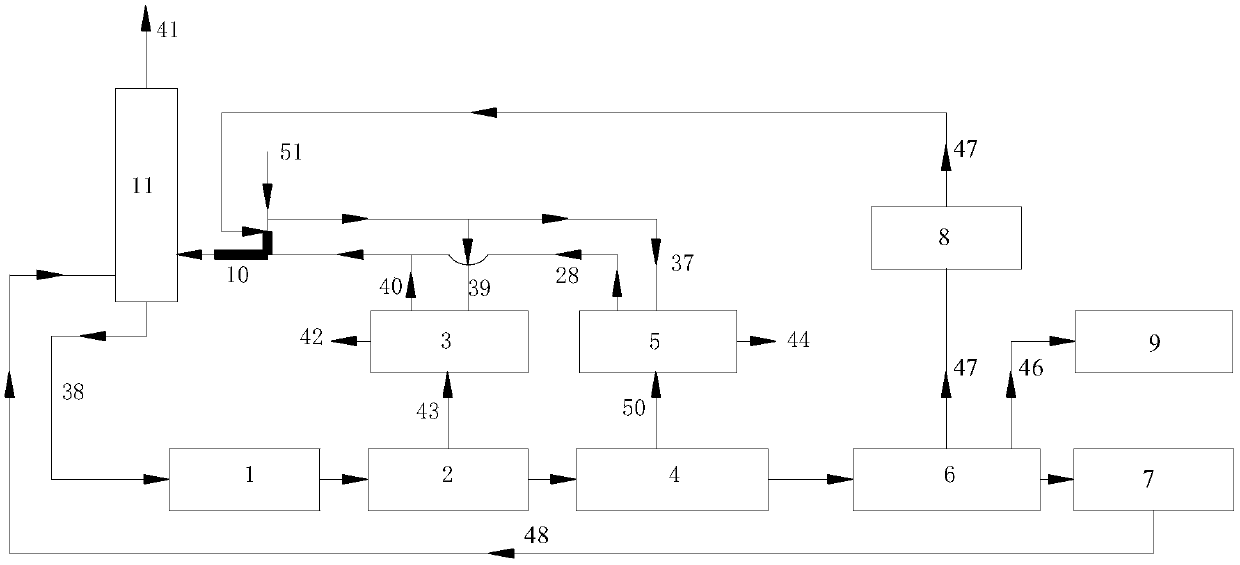

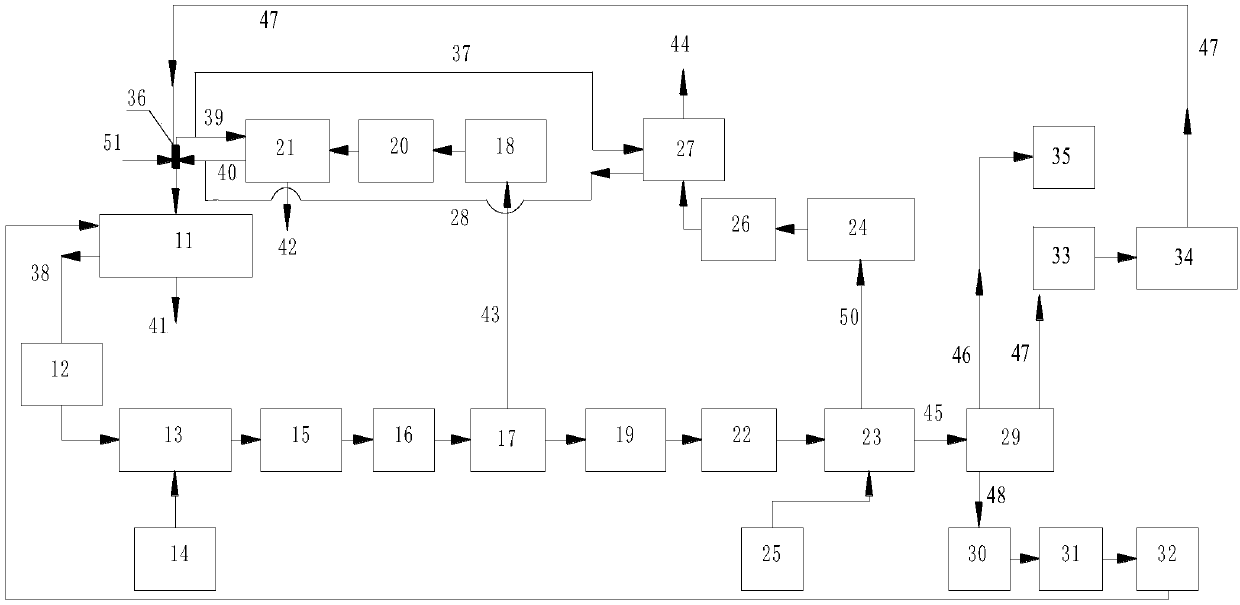

[0051] A method of using the process system provided by this application to realize the resource utilization of flue gas wet desulfurization and denitrification wastewater. The structure of the process system is as follows: figure 1 and 2 shown, including the following steps:

[0052] (1) The wastewater from the flue gas desulfurization and denitrification system is pumped into the coagulation and sedimentation device by the wastewater pump, and mixed with the flocculant from the flocculant addition system in the coagulation and sedimentation device, flocculated and precipitated to remove suspended solids and color in the wastewater Degree,...

Embodiment 2

[0061] This embodiment is applied to the treatment of biomass boiler flue gas and its desulfurization and denitrification wastewater resource treatment, in which biomass boiler flue gas particulate matter, SO 2 , NOx initial emission concentration is 38mg / m 3 , 12mg / m 3 、311mg / m 3 .

[0062] A method of using the process system provided by this application to realize the resource utilization of flue gas wet desulfurization and denitrification wastewater. The structure of the process system is as follows: figure 1 and 2 shown, including the following steps:

[0063] (1) The wastewater from the flue gas desulfurization and denitrification system is pumped into the coagulation and sedimentation device by the wastewater pump, and mixed with the flocculant from the flocculant addition system in the coagulation and sedimentation device, flocculated and precipitated to remove suspended solids and color in the wastewater Degree, etc., after treatment, clear water containing sulfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com