Preparation method and application of polysaccharides from herba leonuri

A technology of motherwort and polysaccharides, applied in the field of medicine, can solve the problems of undiscovered literature reports on the separation, preparation and use of homogeneous polysaccharides, achieve good social and economic benefits, increase extraction rate, and shorten extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: the preparation method of motherwort thick polysaccharide crude product (LAP)

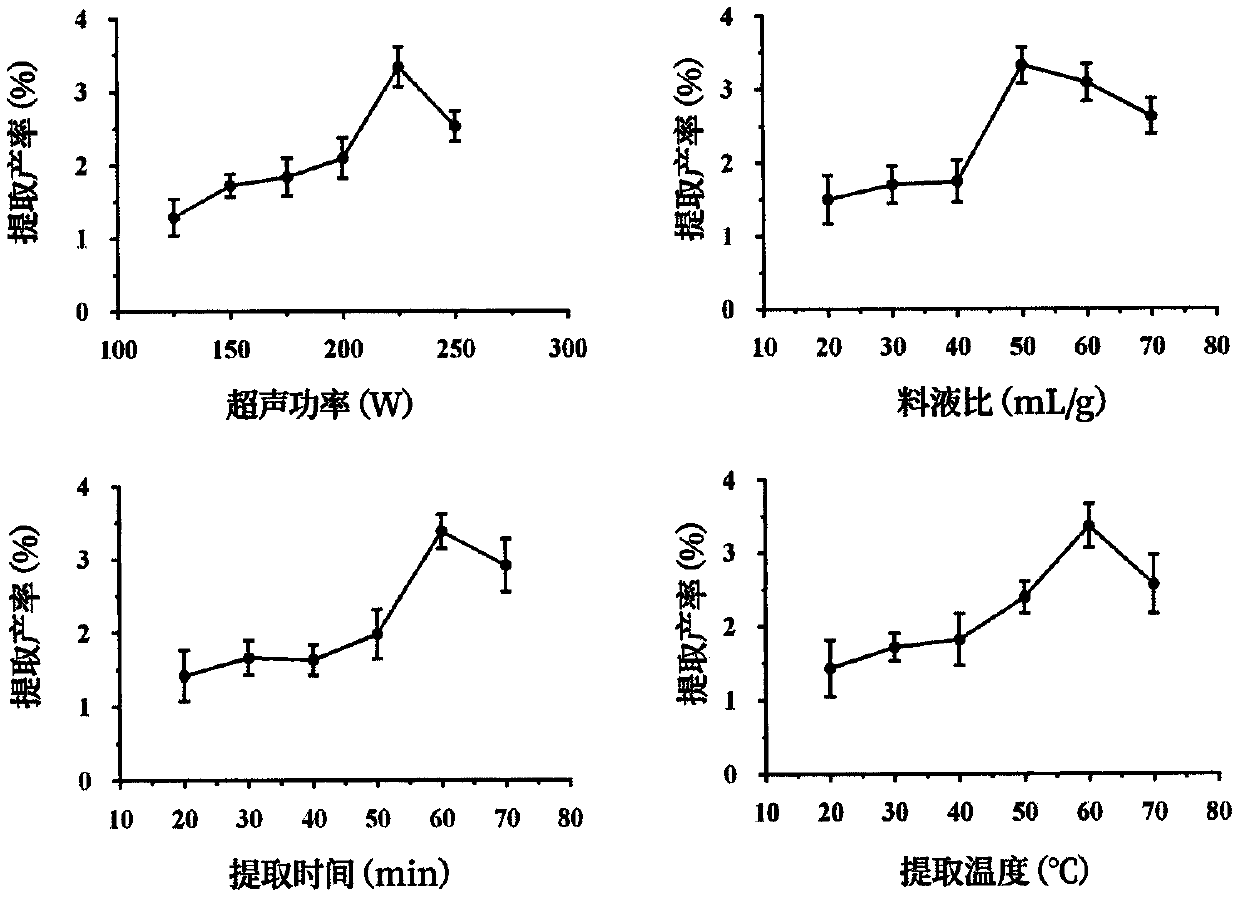

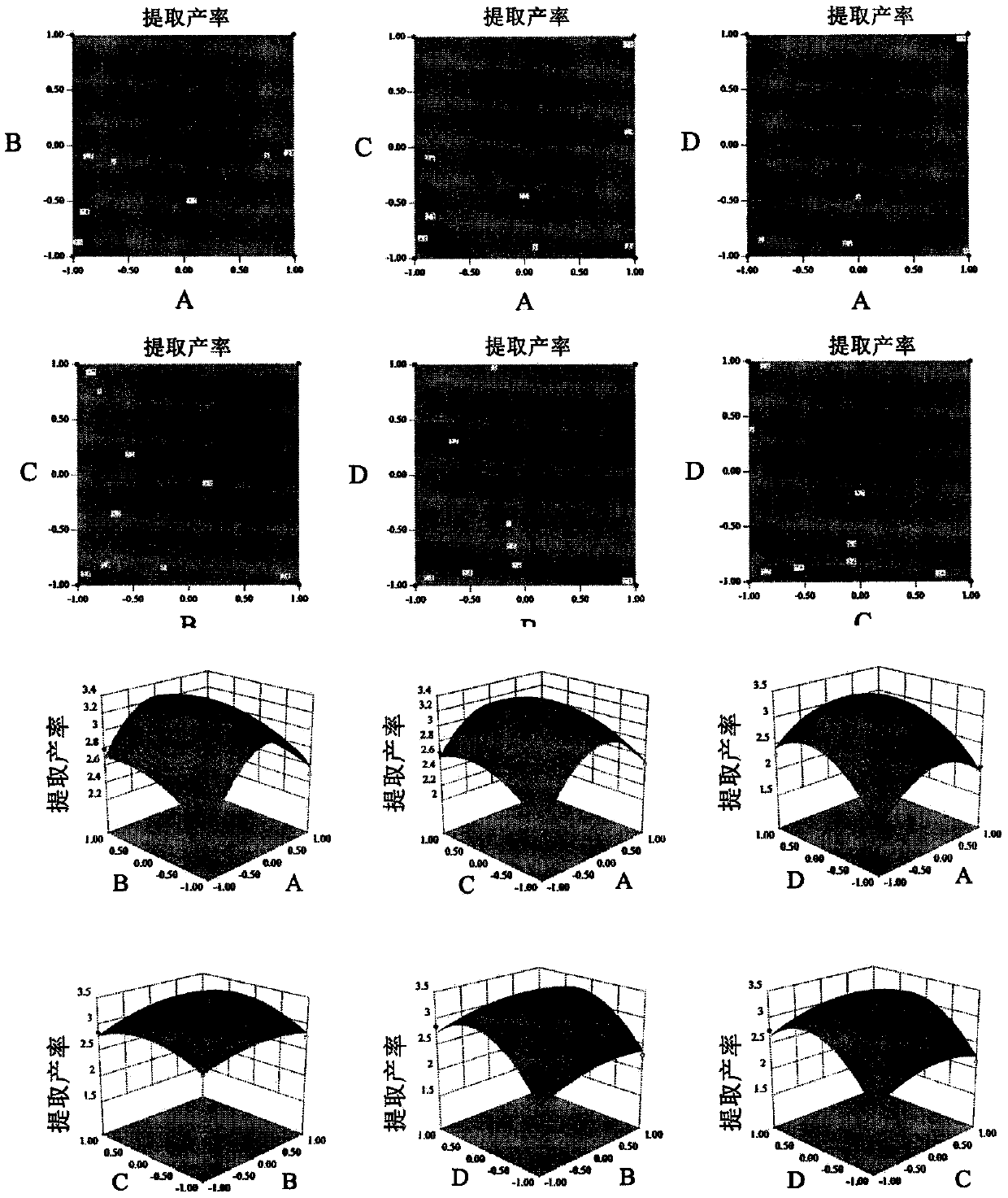

[0040] Weigh 10 g of whole motherwort herb that has been crushed and passed through an 80-mesh sieve into an extraction container, add 5 times the volume of ethanol, reflux and degrease for 3 hours, remove the supernatant with 6 layers of gauze, and dry the sample. Put the dried sample in the reaction vessel, add 200-700ml of deionized water, and extract it with ultrasonic method. The ultrasonic extraction is specifically as follows: add deionized water according to the ratio of material to liquid 20-70mL / g, the extraction time is 20-70min, the extraction temperature is 20-70°C, and the ultrasonic power is 100-250W; after the extraction is completed, filter to obtain the extracted solution, concentrate the extract, add anhydrous petroleum ether to the polysaccharide solution, stir and oscillate to make it milky, leave it to stand until the solution is layered up and down, and rem...

Embodiment 2

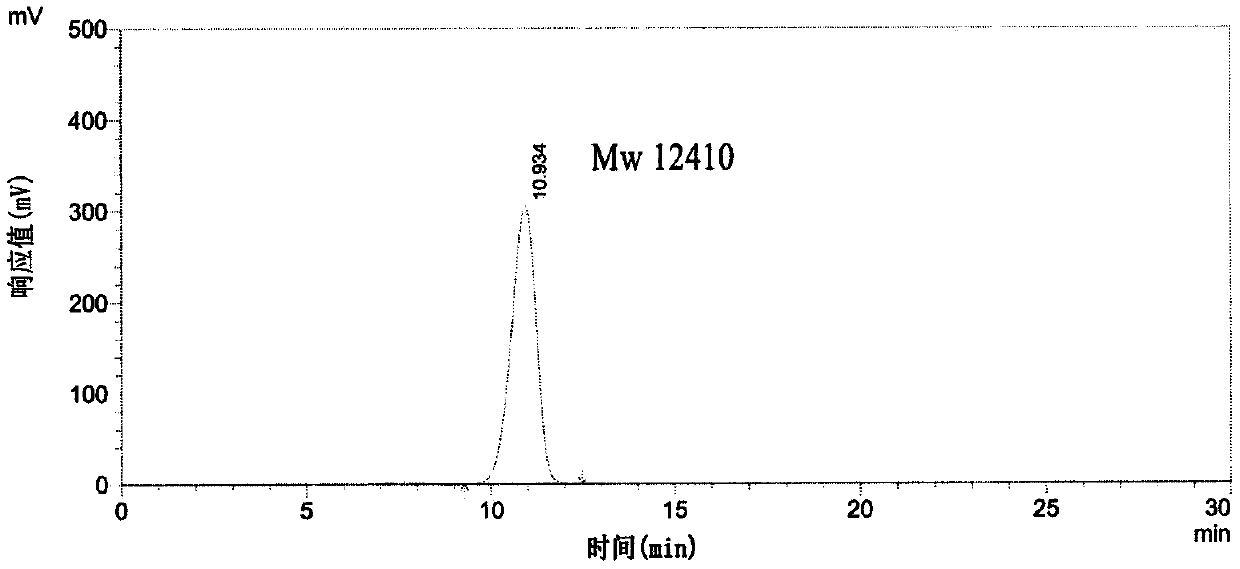

[0051] Embodiment 2: the preparation method of motherwort homogeneous polysaccharide (LAP-1)

[0052] Take 200 mg of motherwort polysaccharide crude product (LAP), fully dissolve it in deionized water, and put it on a well-balanced DEAE-52 ion-exchange column, the specification is (2.6×30cm), the balance liquid is deionized water, and the sample volume is 10ml. It was eluted with 300ml deionized water, then eluted with 0-2mol / L NaCl solution, collected in sections, tracked and detected by the sulfuric acid phenol method, and combined the same components. The water-washed fraction of Leonurus polysaccharide separated by ion-exchange column was chromatographed on Sephacryl S-400 molecular sieve column and eluted with deionized water. The column size is (1.0×100cm), collected in sections, tracked and detected by the sulfuric acid phenol method, and combined the same components. Freeze-dry to obtain the homogeneous motherwort homopolysaccharide (LAP-1).

Embodiment 3

[0053] Embodiment 3: Determination of physicochemical properties of motherwort homogeneous polysaccharide (LAP-1)

[0054] 1. Determination of polysaccharide content

[0055] Accurately weigh an appropriate amount of the sample to be tested and dried to constant weight, and prepare a 0.1mg / mL polysaccharide solution. Use the sulfuric acid phenol method and the m-hydroxybiphenyl method to measure the total sugar and acid sugar content by spectrophotometry at 490nm and 525nm. Glucose calculation The total sugar content of the motherwort polysaccharide crude product (LAP) is 52.23±2.89%, the acid sugar content is 9.67±1.12%, the total sugar content of the motherwort homogeneous polysaccharide (LAP-1) is 92.11±4.97%, and the acid sugar content is 26.50±2.09% %.

[0056] 2. Determination of protein content

[0057] Precisely weigh 10 mg of the sample to be tested and dry it to constant weight, prepare it into a 1 mg / mL polysaccharide solution, and measure it. Use the Coomassie br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| optical rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com