Method for preferred orientation growth of rutile titanium dioxide nanowire arrays on crystal face (001)

A nanowire array, titanium dioxide technology, applied in nanotechnology, liquid chemical plating, metal material coating technology and other directions, can solve problems such as the inability to guarantee preferential orientation growth, and achieve good ultraviolet stimulated light characteristics, low cost, good The effect of preferential growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

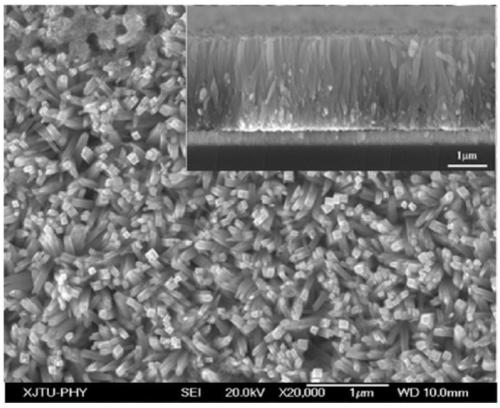

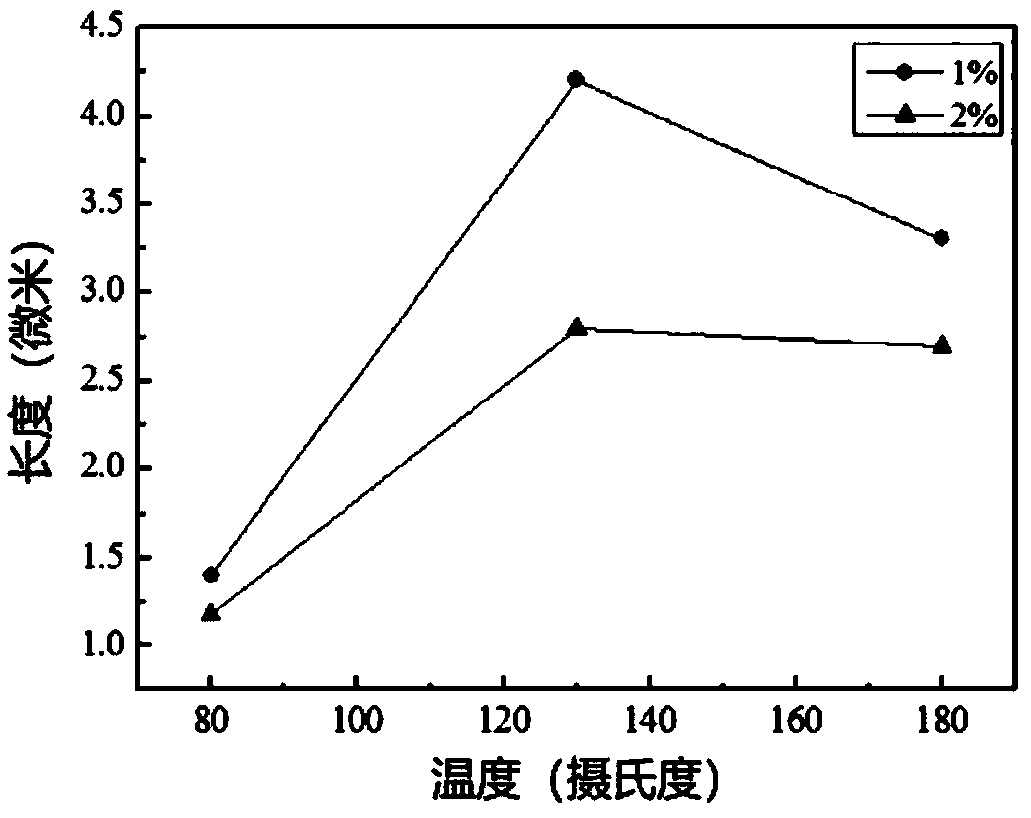

Embodiment 1

[0056] 1) With tetrabutyl titanate (Ti(OBu) 4 ) is the solute, the mixed solution of acetylacetone, ethylene glycol methyl ether and acetone is the solvent, the volume ratio of acetylacetone, ethylene glycol methyl ether and acetone is 1:1:0.5, and the concentration of preparing tetrabutyl titanate is 0.1 mol / L precursor solution;

[0057] 2) Dissolving 1% molar chromium chloride relative to the titanium ion concentration in the mixed solution of step 1) as Cr ion doping;

[0058] 3) Seal the solution doped with Cr ions, put it into a constant temperature water bath, and stir it magnetically at a constant temperature of 60°C to obtain a transparent and uniform sol;

[0059] 4) Deposit the sol obtained above on the cleaned FTO glass sheet by using the spin coating process at a speed of 2000r / min, and then put the spin-coated substrate into a drying oven at 200°C to bake the solvent. Fully volatilize, and finally put the substrate into an annealing furnace, and anneal at 450°C...

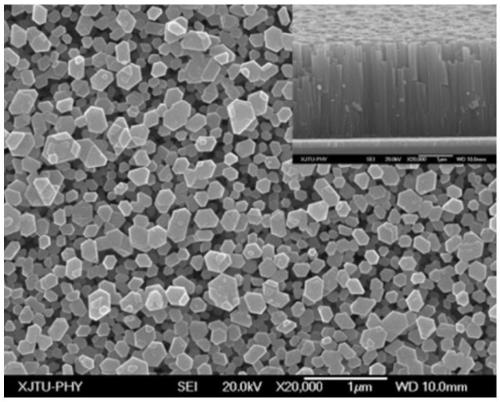

Embodiment 2

[0063] 1) With tetrabutyl titanate (Ti(OBu) 4 ) is the solute, the mixed solution of acetylacetone, ethylene glycol methyl ether and acetone is the solvent, the volume ratio of acetylacetone, ethylene glycol methyl ether and acetone is 1:1:0.5, and the concentration of preparing tetrabutyl titanate is 0.2 mol / L precursor solution;

[0064] 2) Dissolving 1% molar chromium chloride relative to the titanium ion concentration in the mixed solution of step 1) as Cr ion doping;

[0065] 3) Seal the solution doped with Cr ions, put it into a constant temperature water bath, and stir it magnetically at a constant temperature of 60°C to obtain a transparent and uniform sol;

[0066] 4) Deposit the sol obtained above on the cleaned FTO glass sheet by using the spin coating process at a speed of 2000r / min, and then put the spin-coated substrate into a drying oven at 250°C to bake the solvent. Fully volatilize, and finally put the substrate into an annealing furnace, and anneal at 450°C...

Embodiment 3

[0070] 1) With tetrabutyl titanate (Ti(OBu) 4 ) is the solute, the mixed solution of acetylacetone, ethylene glycol methyl ether and acetone is the solvent, the volume ratio of acetylacetone, ethylene glycol methyl ether and acetone is 1:1:0.5, and the concentration of preparing tetrabutyl titanate is 0.3 mol / L precursor solution;

[0071] 2) Dissolving 1% molar chromium chloride relative to the titanium ion concentration in the mixed solution of step 1) as Cr ion doping;

[0072] 3) Seal the solution doped with Cr ions, put it into a constant temperature water bath, and stir it magnetically at a constant temperature of 60°C to obtain a transparent and uniform sol;

[0073] 4) Deposit the sol obtained above on a cleaned FTO glass sheet by using the spin coating process at a speed of 2500r / min, and then put the spin-coated substrate into a drying oven at 250°C to bake the solvent. Fully volatilize, and finally put the substrate into an annealing furnace, and anneal at 450°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com