Preparation method of adsorption filter element used for treating radioactive waste liquid and adsorption filter element

An adsorption filter element and modification technology, which is applied in the field of wastewater treatment, can solve the problems of destruction of the adsorption bed, overall performance decline, pollution treatment process, etc., and achieve the effect of large adsorption surface area, compact filter element structure and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

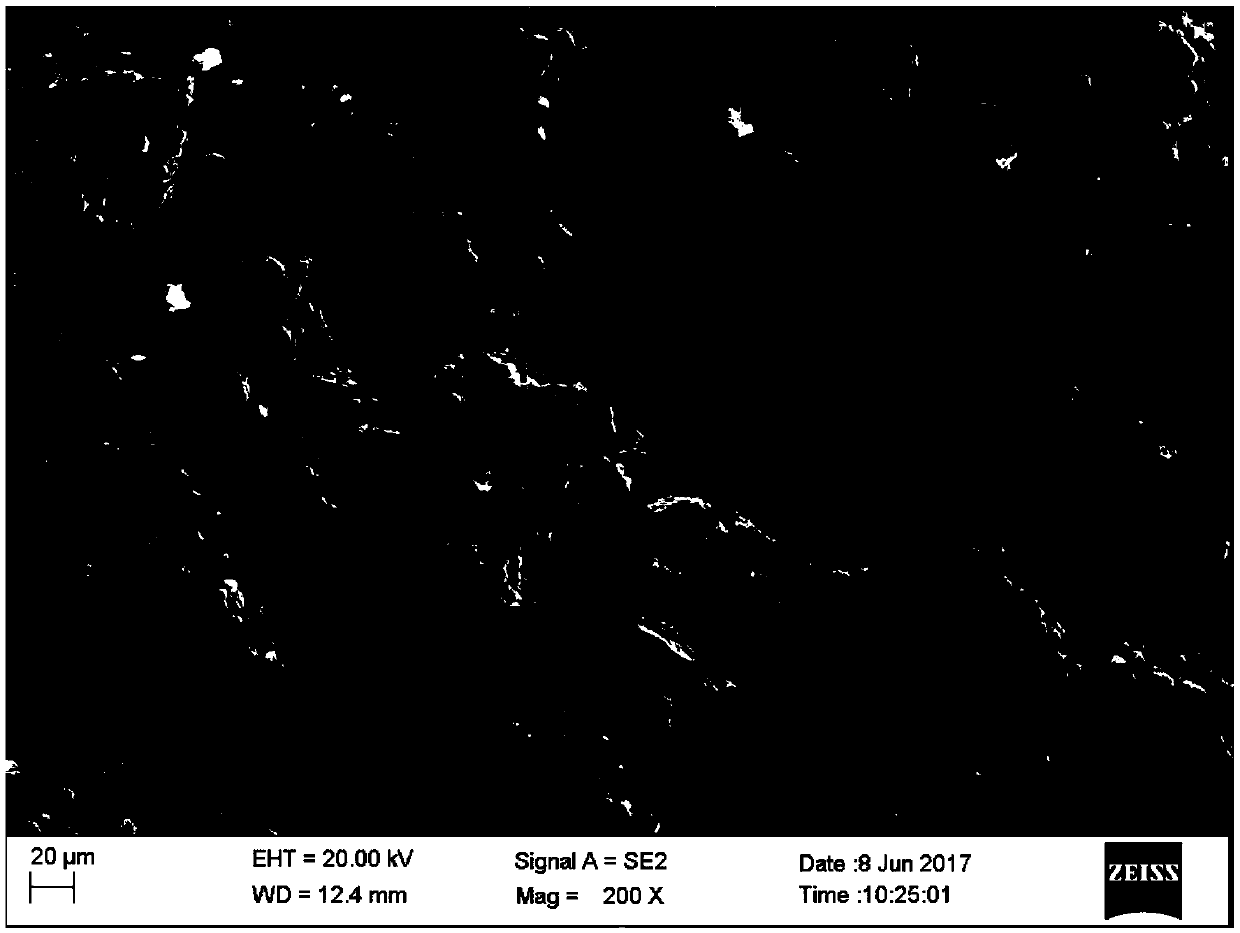

[0035] The preparation method of the adsorption filter core of the present invention comprises the steps of modifying the porous material mixture with zero-valent iron after grinding, mixing with the ground binder and high-density extrusion molding. The porous material is a microporous material with a pore size of 0.01 μm to 10 μm, such as a mixture of zeolite powder, bentonite, kaolin, graphene, and alumina. The adhesive used for extrusion molding of the porous material is Polyacrylonitrile or ultra-high molecular weight polyethylene. The density of the filter element is 5000kg / m 3 Above, such as 10000-80000kg / m 3 , preferably 30000-50000kg / m 3 .

[0036] The zeolite powder, bentonite, kaolin, graphene, and alumina used in the present invention are all microporous materials with rich and well-developed pore structures. After grinding, the particle size of the powder and the adhesive is controlled above 200 mesh, such as 300 mesh. ~500 mesh, and then modified by zero-valen...

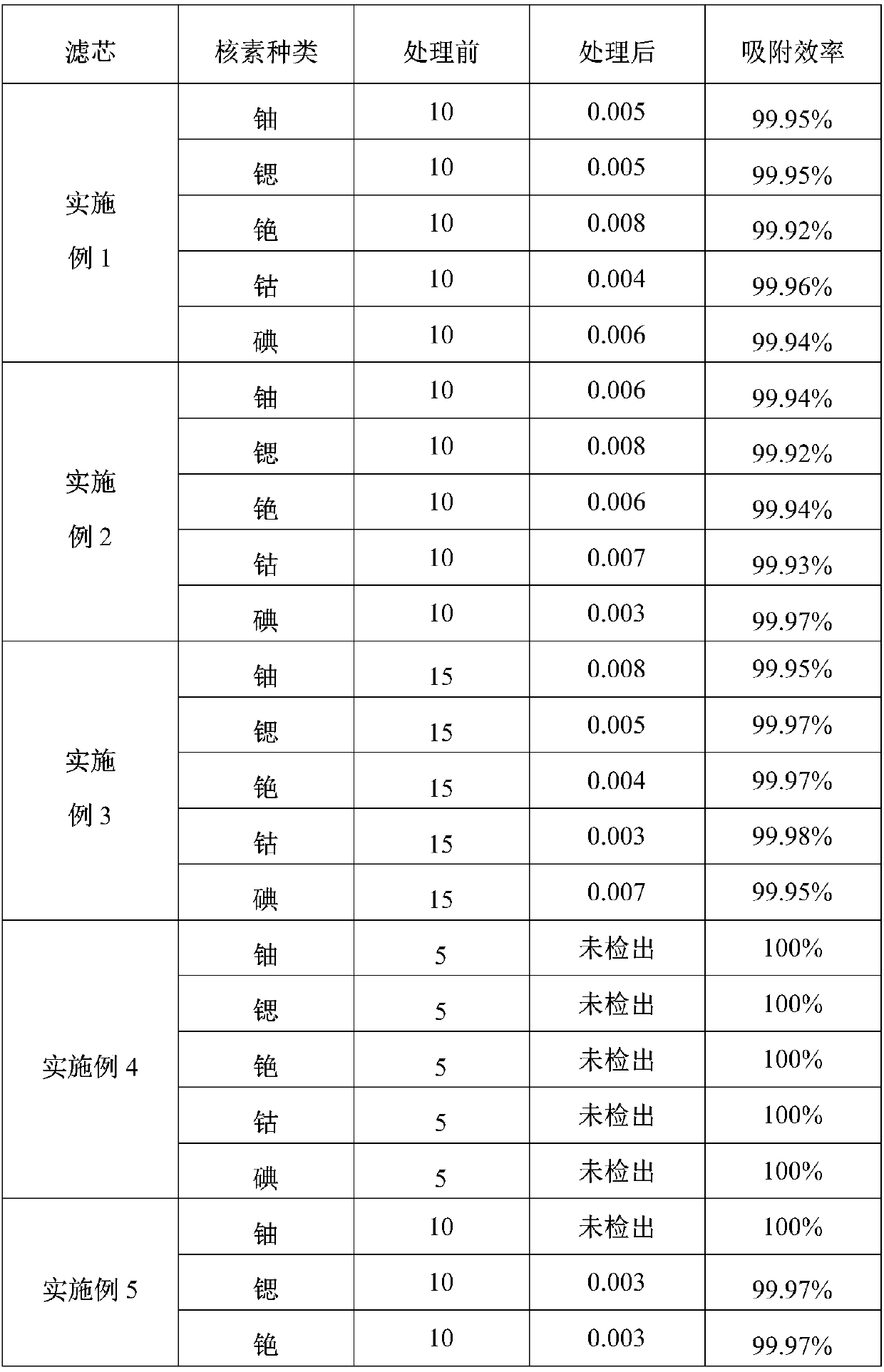

Embodiment 1

[0041] (1) Weigh 3250g of modified zeolite powder, 750g of calcium-based bentonite, 400g of calcined kaolin, 350g of activated alumina, 25g of graphene oxide, and mix uniformly; the modified zeolite powder is a modified zeolite treated with 10% hydrochloric acid pink;

[0042] (2) The mixture is fully ground, and the average particle diameter of the controlled grinding mixed powder particles is 300 mesh;

[0043] (3) Soak the mixed powder in an aqueous solution with a starch content of 5%, a ferrous ion content of 4%, and a pH of 8 at room temperature for 20 minutes, then take it out and dry it;

[0044] (4) taking out the dried powder in the step (3) after being soaked for 5 minutes in the sodium borohydride aqueous solution of pH 8.5;

[0045] (5) Heat the air-dried powder in step (4) to about 380°C at a heating rate of 100°C / h under nitrogen protection, keep it warm for 2.5 hours, cool it down to below 120°C, and take it out to cool down naturally;

[0046] (6) Microwave dr...

Embodiment 2

[0054] (1) Take by weighing 3000g of modified zeolite powder, 650g of calcium-based bentonite, 350g of calcined kaolin, 300g of activated alumina, 15g of graphene oxide, and mix uniformly;

[0055] (2) The mixture is fully ground, and the average particle diameter of the controlled grinding mixed powder particles is 300 mesh;

[0056] (3) Soak the mixed powder in an aqueous solution with a starch content of 5%, a ferrous ion content of 4%, and a pH of 7.5 at room temperature for 25 minutes, then take it out and dry it;

[0057] (4) taking out the dried powder in the step (3) after being soaked in an aqueous solution of sodium borohydride with a pH of 9 for 4 minutes;

[0058] (5) Heat the dried powder in step (4) to about 420°C at a heating rate of 80°C / h under nitrogen protection, keep it warm for 3 hours, cool it down to below 120°C, and take it out to cool down naturally;

[0059] (6) Microwave drying the modified mixed powder obtained in step (5) at 400°C for 6.5 hours; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com