Preparation method of high-temperature ultra-low sodium alumina powder material

A technology of alumina powder and ultra-low sodium, applied in chemical instruments and methods, alumina/aluminum hydroxide, inorganic chemistry, etc. To achieve ultra-low sodium level and other issues, to achieve the effect of superior performance, low manufacturing cost and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

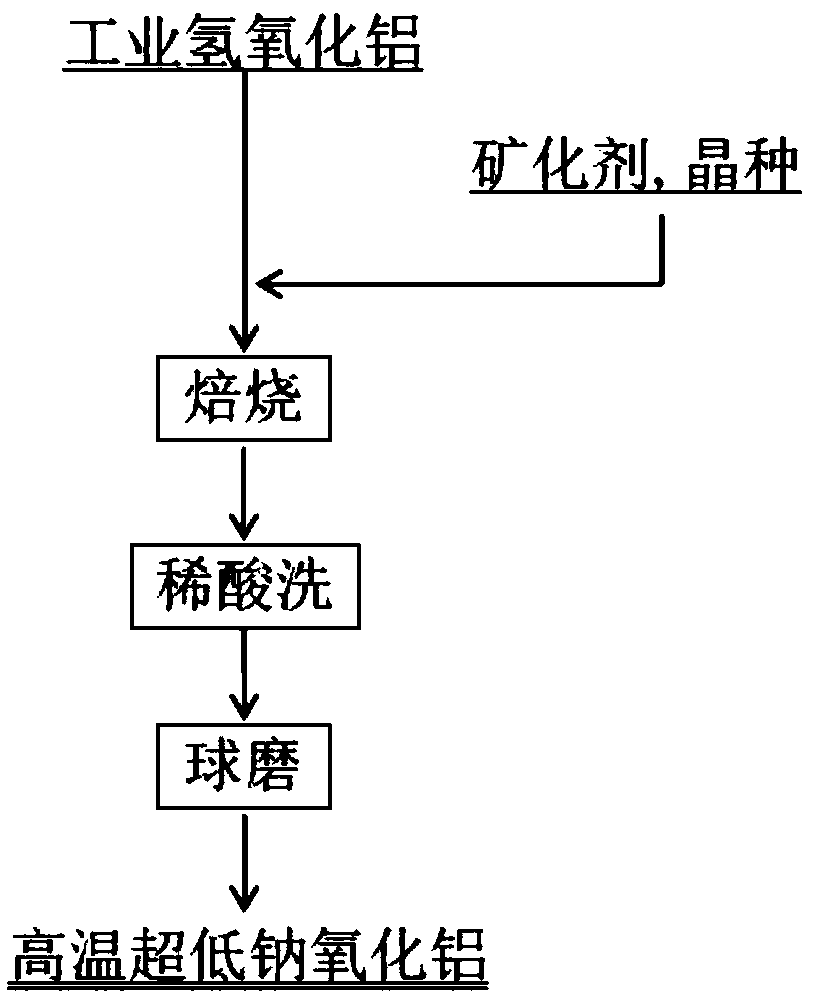

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of high-temperature ultra-low sodium alumina is carried out according to the following steps:

[0035] (1) Spread the industrial aluminum hydroxide flat on a tray, place it in an oven, and dry it at a temperature of 110° C. for 2 to 3 hours to obtain pretreated aluminum hydroxide.

[0036] (2) Mix the pretreated aluminum hydroxide with 0.1% ammonium chloride mineralizer and 0.05% nano-a-alumina seeds uniformly, and place the mixture in a muffle furnace at a temperature of 8°C / min The heating rate is increased to 1400°C, roasted for 30 minutes, and then dropped to room temperature with the furnace to obtain high-temperature alumina.

[0037] (3) The high-temperature alumina obtained above is dilute acid washed with a liquid-solid ratio of 3:1 in a constant temperature magnetic stirrer, the addition amount of dilute hydrochloric acid is 0.012%, the pickling temperature is 50°C, and the magnetic stirring speed is 120r / min. , Stirring time is 20min, washing b...

Embodiment 2

[0040] A preparation method of high-temperature ultra-low sodium alumina is carried out according to the following steps:

[0041] (1) Spread the industrial aluminum hydroxide flat on a tray, place it in an oven, and dry it at a temperature of 110°C for 2 to 3 hours to obtain pretreated aluminum hydroxide with a particle size D (0.5) of about 70 μm.

[0042] (2) Mix the pretreated aluminum hydroxide with 0.1% ammonium chloride mineralizer and 0.05% basic magnesium carbonate seed crystals uniformly, and place the mixture in a muffle furnace at a temperature of 10°C / min The rate was increased to 1400°C, calcined for 20 minutes, and dropped to room temperature with the furnace to obtain high-temperature alumina with w[α-alumina]>96%.

[0043] (3) The high-temperature alumina obtained above is dilute acid washed with a liquid-solid ratio of 4:1 in a constant temperature magnetic stirrer, the addition amount of dilute hydrochloric acid is 0.012%, the pickling temperature is 50°C, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com