Eco-friendly river lake arsenic in-situ treatment composite material and preparation method and application thereof

An in-situ treatment and composite material technology, applied in the field of environmental application materials, can solve problems such as secondary pollution water quality risks, and achieve the effects of reducing secondary pollution risks, reducing bioavailability, and reducing arsenic toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

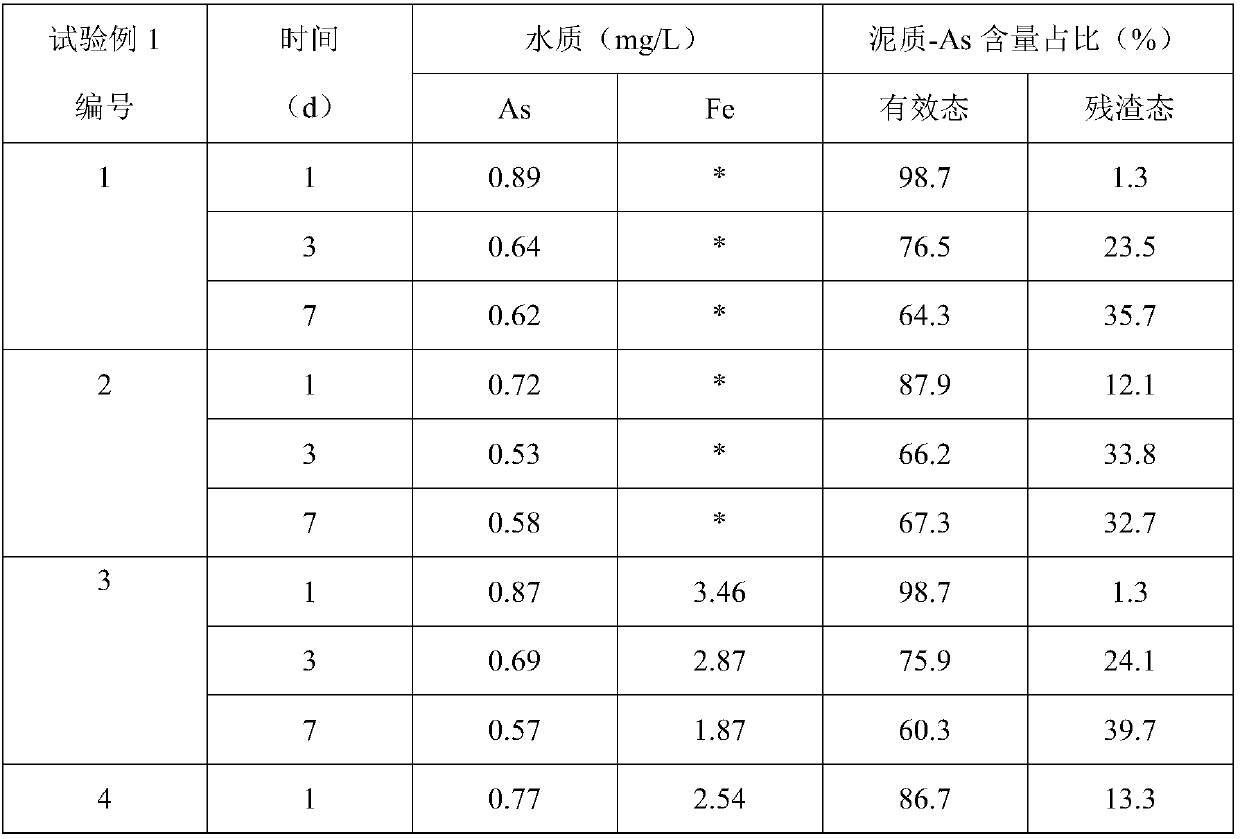

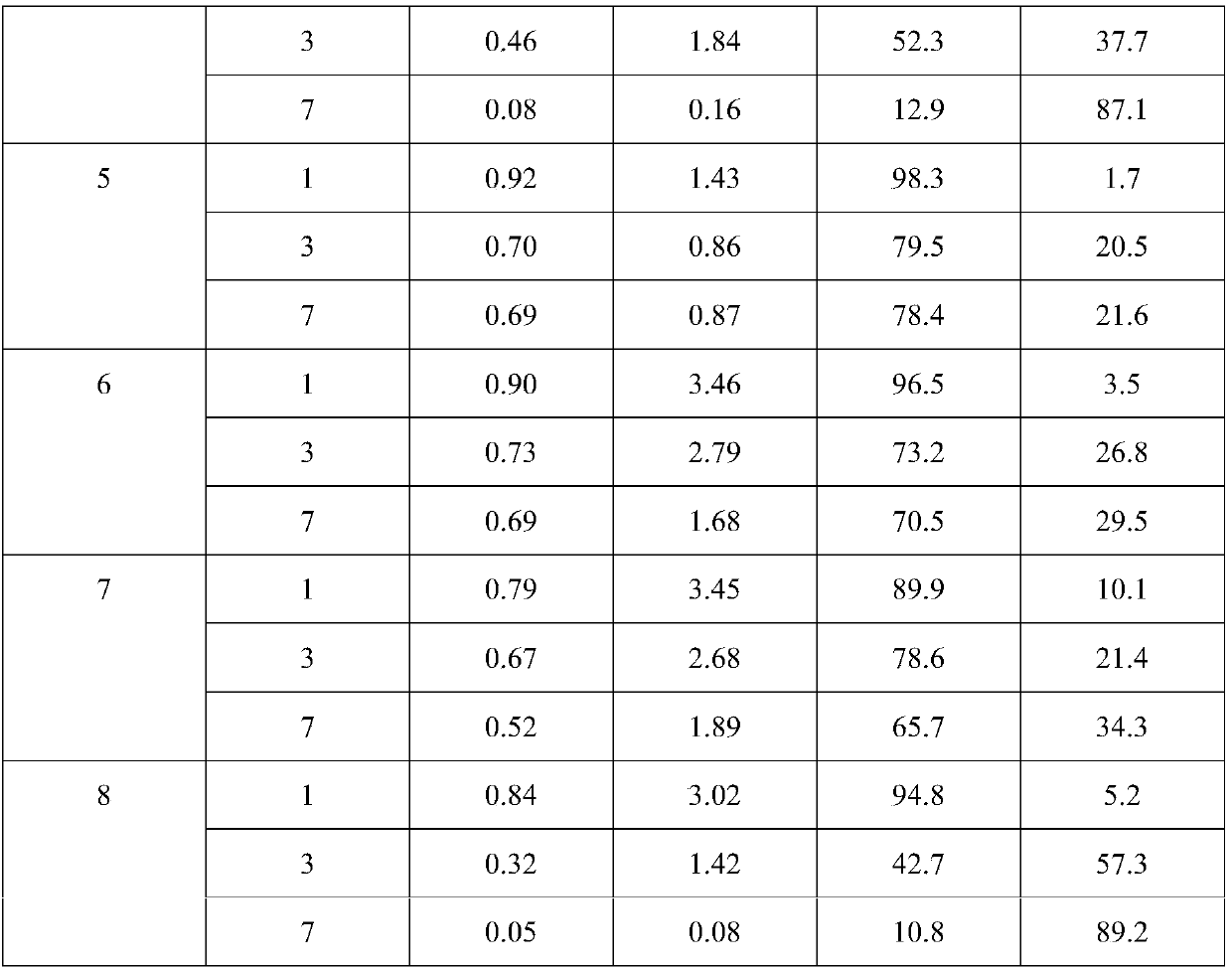

Examples

Embodiment 1

[0034] 1. Non-metallic minerals-biomass charcoal series:

[0035] (1) Corn stalk biochar (referred to as BC): The corn stalks purchased in the market were washed, dried, and impurities were removed, and then ground and pulverized. Finally, in a tube furnace, nitrogen was used as a protective gas, and the temperature was raised to 500°C at a rate of 5°C / min. After constant temperature pyrolysis for 4 hours, the temperature was naturally lowered, and kept for later use.

[0036] (2) iron reform (denoted as BC Fe ): Weigh an appropriate amount of BC and FeCl 3 Under the ratio of iron-carbon mass ratio of 1:1 and 1:5 respectively, impregnate and stir for 8 hours, then bake in a blast drying oven at 60°C for 5 hours, take it out in a muffle furnace and incinerate at 400°C for 2 hours, cool down Sealed and stored for later use, respectively marked as BC Fe1 and BC Fe0.2 .

[0037] (3) Immobilized microorganisms (denoted as BC Fe1 -PSB): Wrap BC with carbonized cotton cloth Fe...

Embodiment 2

[0042] (1) After washing, drying and removing impurities, activated carbon purchased on the market is ground and pulverized. Finally, in a tube furnace, nitrogen was used as a protective gas, and the temperature was raised to 500°C at a rate of 5°C / min. After constant temperature pyrolysis for 4 hours, the temperature was naturally lowered, and kept for later use.

[0043] (2) iron reform: take the activated carbon and FeCl that step (1) obtains 3 Under the ratio of iron to carbon mass ratio of 1:10, impregnate and stir for 10 hours, then bake in 80°C blast drying oven for 4h, take it out and incinerate at 500°C for 1h in a muffle furnace, cool down and seal it for later use .

[0044] (3) Immobilized microorganisms: wrap step (2) with carbonized cotton cloth to obtain the iron-modified non-metallic mineral carrier. In the solution, wrap the carrier with carbonized cotton cloth: Bacillus subtilis bacteria solution = 1: 50g / mL, cultivate and acclimatize for 36 hours at 20°C, ...

Embodiment 3

[0049] (1) After the kaolin purchased in the market is washed, dried, and impurities are removed, it is ground and pulverized. Finally, in a tube furnace, nitrogen was used as a protective gas, and the temperature was raised to 500°C at a rate of 5°C / min. After constant temperature pyrolysis for 4 hours, the temperature was naturally lowered, and kept for later use.

[0050] (2) iron reform: take the activated carbon and FeCl that step (1) obtains 3 Under the ratio of iron to carbon mass ratio of 1:10, impregnate and stir for 10 hours, then bake in 80°C blast drying oven for 4h, take it out and incinerate at 500°C for 1h in a muffle furnace, cool down and seal it for later use .

[0051] (3) Immobilized microorganisms: use carbonized cotton cloth to wrap step (2) to obtain the iron-modified non-metallic mineral carrier, and the carbonized cotton cloth is 5% of the quality of the iron-modified non-metallic mineral carrier, and then contain 7.5 billion CFU / mL PSB (photosyntheti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com