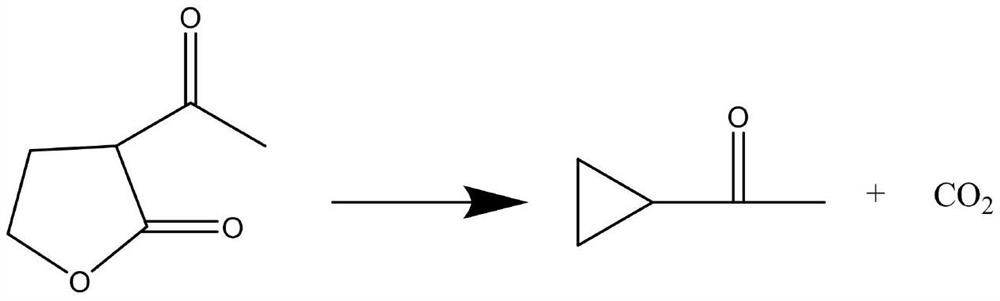

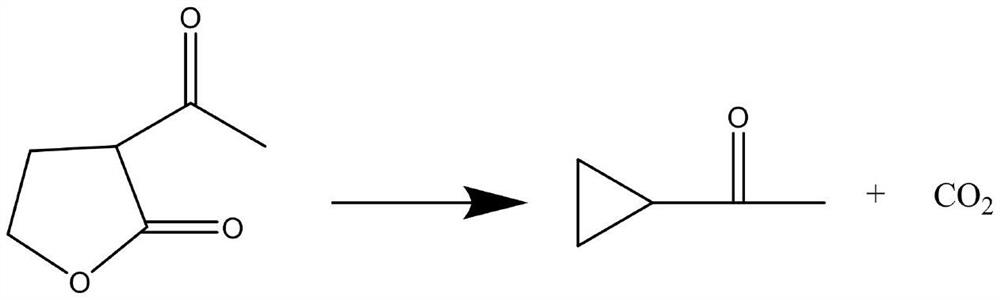

A kind of synthetic method of cracking and preparing cyclopropyl methyl ketone

A technology of cyclopropylmethyl ketone and its synthesis method, which is applied in chemical instruments and methods, preparation of carbon-based compounds, preparation of organic compounds, etc., can solve the problems of strong corrosion, high cost, and low product yield, and achieve High selectivity, avoiding three wastes and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) In the jacketed reactor, add 200 g of solvent dimethyl sulfoxide, add 10 g of catalyst (sodium chloride: ZIF-67=1:0.1), start stirring, start heating, and raise the temperature to 100 ° C;

[0026] 2) At a temperature of 100°C, α-acetyl-γ-butyrolactone is slowly and continuously added to cause a catalytic cracking reaction, and at the same time, the cracking product cyclopropyl methyl ketone is continuously extracted through a rectification tower.

[0027] 3) After the raw material feeding is completed, continue to distill and extract for 2 hours, and collect the complete product cyclopropyl methyl ketone. After the reaction, the obtained solvent and catalyst can be directly used for the preparation of the next batch of cyclopropyl methyl ketone products without any treatment.

[0028] The collected cyclopropyl methyl ketone has a purity of 99.0%, and the total molar yield of the reaction is 98.1%.

Embodiment 2

[0030] 1) In the jacketed reactor, add 200 g of solvent N,N-dimethylformamide, add 50 g of catalyst (sodium iodide: ZIF-67=1:0.5), start stirring, start heating, and raise the temperature to 140°C;

[0031] 2) At a temperature of 140°C, α-acetyl-γ-butyrolactone is slowly and continuously added to cause a catalytic cracking reaction, and at the same time, the cracking product cyclopropyl methyl ketone is continuously extracted through the rectification tower.

[0032] 3) After the raw material feeding is completed, continue to distill and extract for 1 hour, and collect the complete product cyclopropyl methyl ketone. After the reaction, the obtained solvent and catalyst can be directly used for the preparation of the next batch of cyclopropyl methyl ketone products without any treatment.

[0033] The collected cyclopropyl methyl ketone has a purity of 99.8%, and the total molar yield of the reaction is 99.7%.

Embodiment 3

[0035] 1) In the jacketed reactor, add solvent chlorobenzene 200g, add catalyst 20g (potassium iodide: ZIF-67=1:0.2), start stirring, start heating, and raise the temperature to 110°C;

[0036] 2) At a temperature of 110°C, α-acetyl-γ-butyrolactone is slowly and continuously added to cause a catalytic cracking reaction, and at the same time, the cracking product cyclopropyl methyl ketone is continuously extracted through the rectification tower.

[0037] 3) After the raw material feeding is completed, continue to distill and extract for 2 hours, and collect the complete product cyclopropyl methyl ketone. After the reaction, the obtained solvent and catalyst can be directly used for the preparation of the next batch of cyclopropyl methyl ketone products without any treatment.

[0038] The collected cyclopropyl methyl ketone has a purity of 99.3%, and the total molar yield of the reaction is 98.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com