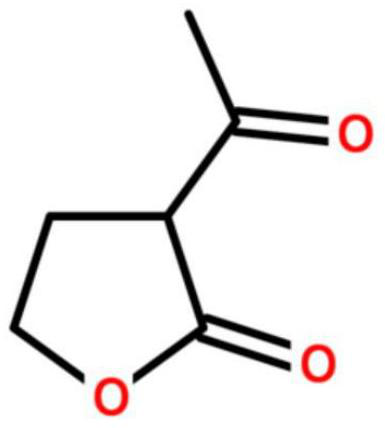

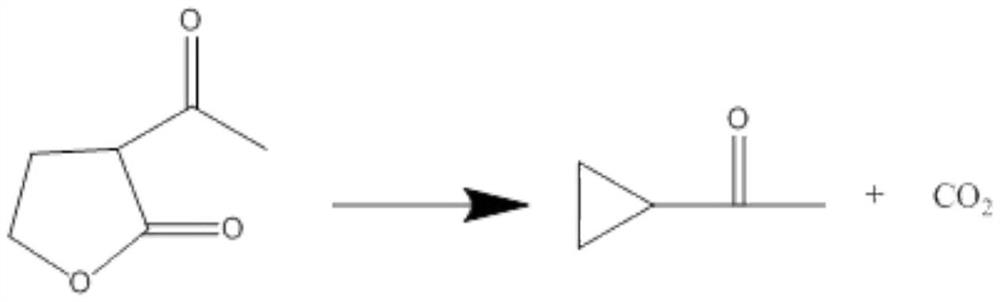

A kind of synthetic method of α-acetyl-γ-butyrolactone cracking to prepare cyclopropyl methyl ketone

A technology of cyclopropyl methyl ketone and synthesis method, which is applied in the direction of heterocyclic compound preparation and organic chemistry, can solve the problems of insufficient catalyst activity, high reaction temperature, low reaction yield, etc., achieve excellent catalytic cracking effect, reduce The effect of pyrolysis reaction temperature and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

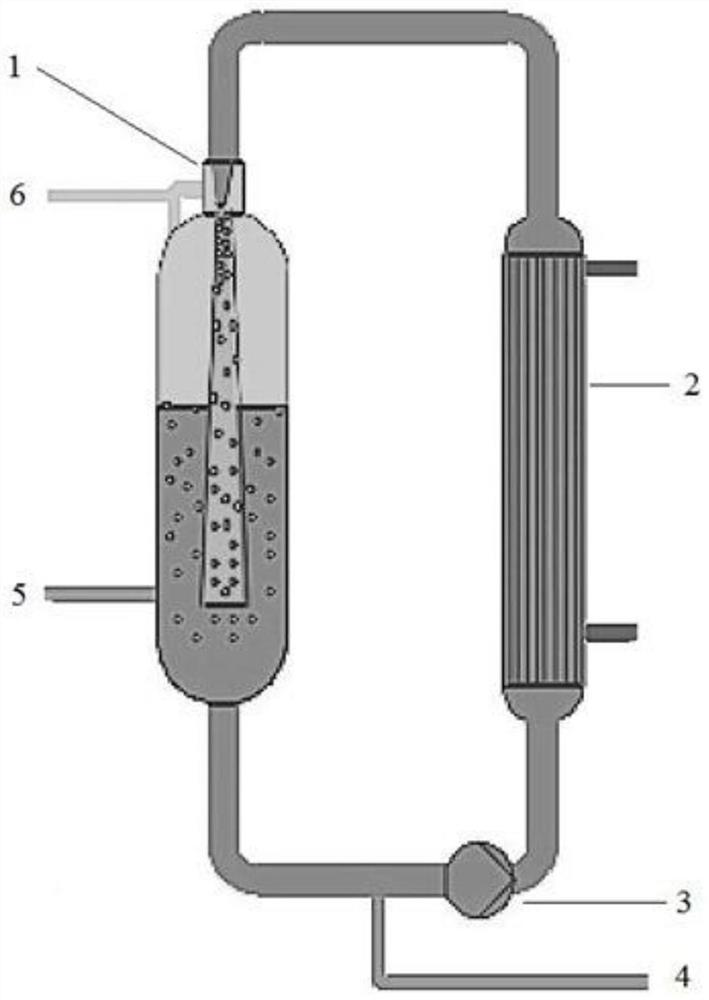

[0032] (1) In the injection loop reactor based on the Venturi effect, add the α-acetyl-γ-butyrolactone raw material, remove oxygen and fill it with inert gas for replacement protection, and turn on the external circulation pump 3 for high-speed injection mixing.

[0033] (2) Turn on the heat exchanger 2, control the temperature at 140°C, slowly add the α-acetyl-γ-butyrolactone raw material and the catalyst through the material inlet 5 into the injection loop reactor, and spray and mix through the injection mixer 1 And realize sufficient catalytic cracking reaction. Catalyst 1.0kg (sodium chloride: ZIF-8=1:0.05), the particle size of the catalyst is less than 2000 microns.

[0034] (3) From the top of the reaction kettle, the pyrolysis product cyclopropyl methyl ketone is continuously condensed and extracted from the cyclopropyl methyl ketone extraction outlet 6, and the waste material is discharged from the sewage outlet 4. At the same time, the raw material of α-acetyl-γ-but...

Embodiment 2

[0036] (1) In the injection loop reactor based on the Venturi effect, add the α-acetyl-γ-butyrolactone raw material, remove oxygen and fill it with inert gas for replacement protection, and turn on the external circulation pump 3 for high-speed injection mixing.

[0037] (2) Turn on the heat exchanger 2, control the temperature at 100°C, slowly add the α-acetyl-γ-butyrolactone raw material and the catalyst through the material inlet 5 into the injection loop reactor, and spray and mix through the injection mixer 1 And realize sufficient catalytic cracking reaction. Catalyst 1.0kg (sodium iodide: ZIF-8=1:0.5), the particle size of the catalyst is less than 500 microns.

[0038] (3) From the top of the reaction kettle, the pyrolysis product cyclopropyl methyl ketone is continuously condensed and extracted from the cyclopropyl methyl ketone extraction outlet 6, and the waste material is discharged from the sewage outlet 4. At the same time, the raw material of α-acetyl-γ-butyrol...

Embodiment 3

[0040] (1) In the injection loop reactor based on the Venturi effect, add the α-acetyl-γ-butyrolactone raw material, remove oxygen and fill it with inert gas for replacement protection, and turn on the external circulation pump 3 for high-speed injection mixing.

[0041](2) Turn on the heat exchanger 2, control the temperature at 130°C, slowly add the α-acetyl-γ-butyrolactone raw material and the catalyst through the material inlet 5 into the injection loop reactor, and spray and mix through the injection mixer 1 And realize sufficient catalytic cracking reaction. Catalyst 1.0kg (potassium iodide: ZIF-8=1:0.1), the particle size of the catalyst is less than 1000 microns.

[0042] (3) From the top of the reaction kettle, the pyrolysis product cyclopropyl methyl ketone is continuously condensed and extracted from the cyclopropyl methyl ketone extraction outlet 6, and the waste material is discharged from the sewage outlet 4. At the same time, the raw material of α-acetyl-γ-buty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com