A kind of molecular sieve catalyst for the catalytic cracking of MTP by-product hydrocarbons and its preparation method

A technology of molecular sieves and catalysts, which is applied in the field of molecular sieve catalysts and their preparation, can solve problems such as separation difficulties, thermal stability and hydrothermal stability reduction of nano-molecular sieves, and achieve rich structural features, good catalytic cracking effect, and reduction of side effects such as aromatics. The effect of product formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

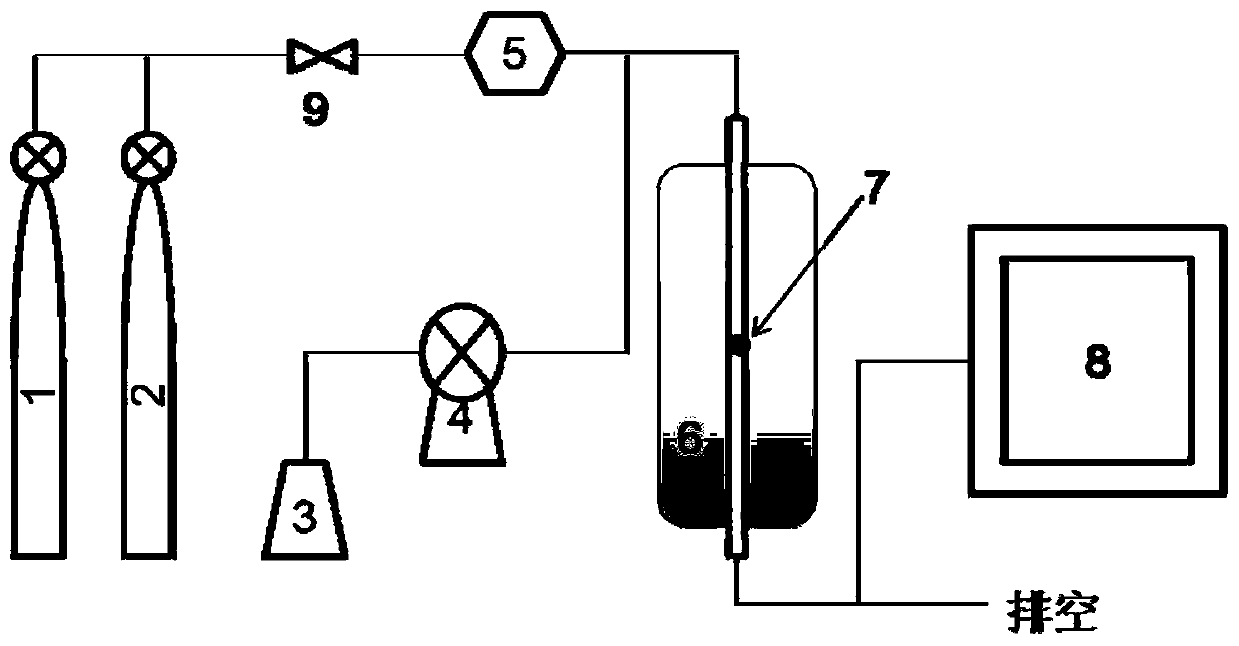

Method used

Image

Examples

Embodiment 1-16

[0080] II. The hydrocarbon cracking catalytic performance evaluation of the modified ZSM-5 molecular sieve catalyst obtained in embodiment 1-16

[0081] The properties of the modified ZSM-5 molecular sieve catalysts obtained in Examples 1-16 were investigated by catalytic cracking of the model compound n-hexane. The catalytic cracking reaction was evaluated in a continuous small fixed-bed reactor. The reaction tube is a φ10mm×430mm quartz tube, the catalyst loading is 0.5-2.0g, the reaction temperature is 550-650°C, and the space velocity is 1-3.0h -1 , the system pressure is normal pressure. The SP-3420 gas chromatograph was used for on-line analysis, and the organic composition in the product was detected by a hydrogen flame ionization detector, and a small amount of dry gas generated during the reaction was ignored. Before the reaction starts, the catalyst is firstly activated under the condition that N 2 The molecular sieve bed was purged for 1 h at a flow rate of 50 L / ...

Embodiment 17

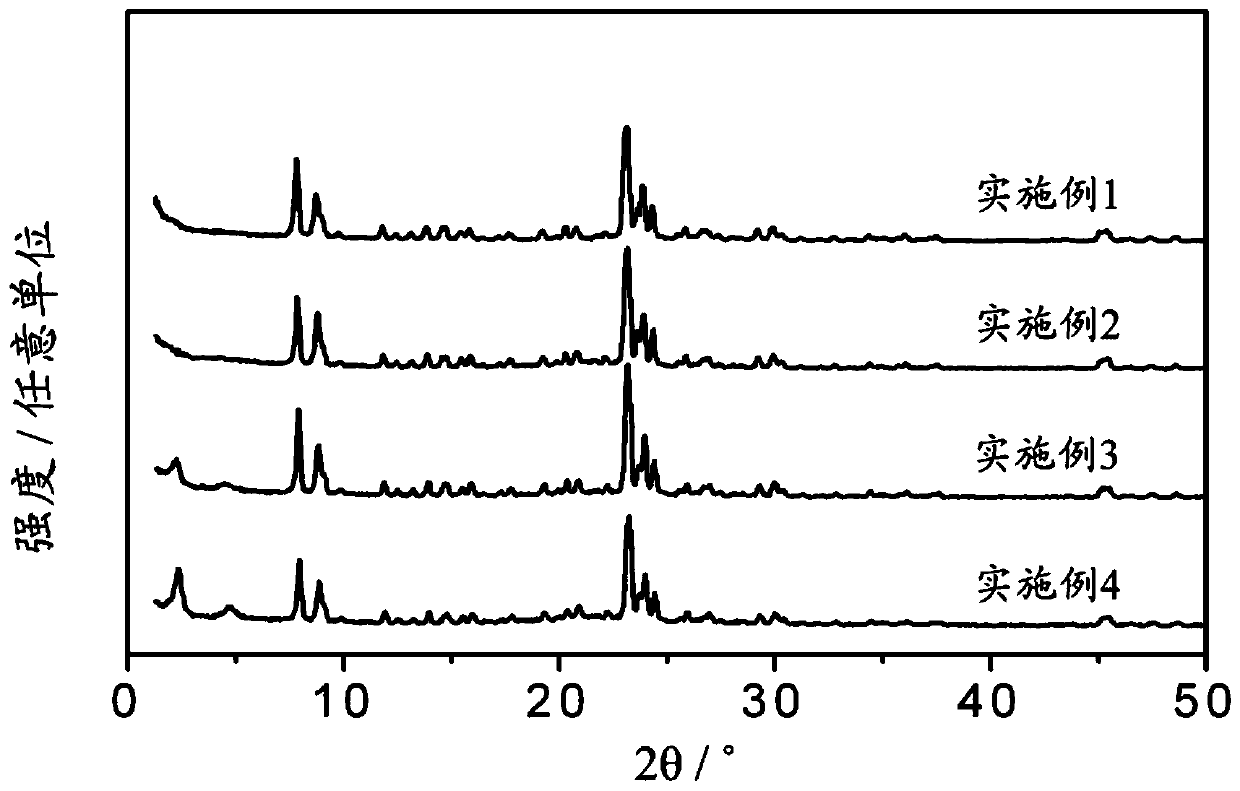

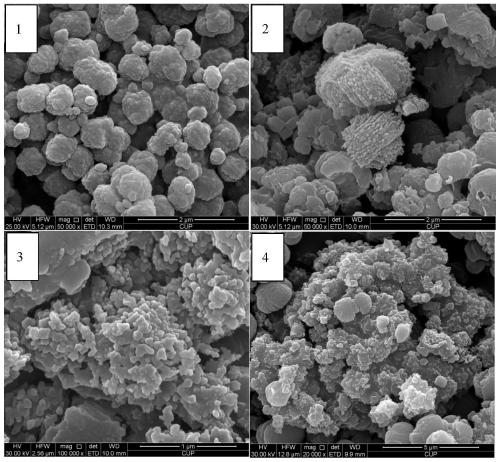

[0084] At normal pressure, the temperature is 625°C, the catalyst loading is 2.0g, and the space velocity is 3h -1 Under the condition, examine different TPXA among the embodiment 1-4 + The catalytic cracking performance of ZSM-5 molecular sieve synthesized by the added amount on n-hexane, and the evaluation results are shown in Table 5.

Embodiment 18

[0086] At normal pressure, the temperature is 625°C, the catalyst loading is 2.0g, and the space velocity is 3h -1 Under certain conditions, the catalytic cracking performance of ZSM-5 molecular sieves with different silicon-aluminum ratios in Examples 5-8 on MTP by-product hydrocarbons was investigated, and the evaluation results are shown in Table 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com