Ultraviolet strong oxygen depth water treatment method and device

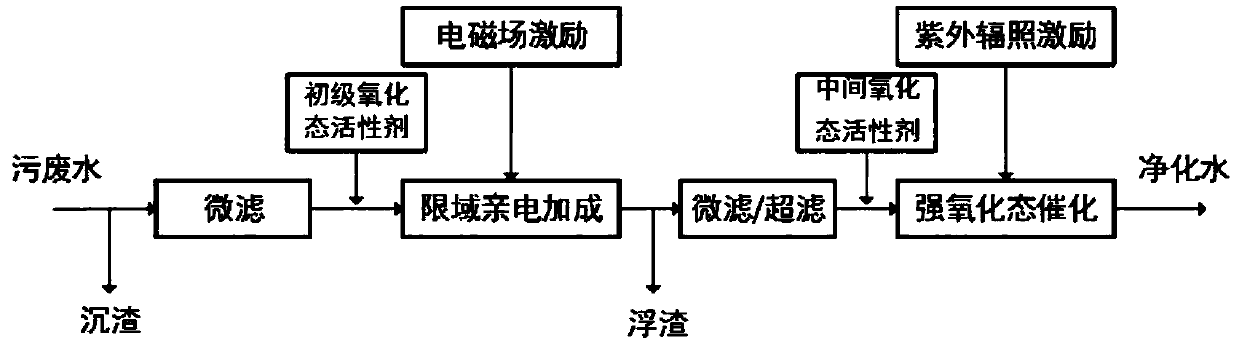

A treatment method and water treatment technology, applied in the direction of oxidation water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the loss of electrode stability, high treatment efficiency of AOP technology, waste of energy or resources, etc. To solve the problem, to achieve the effect of reasonable structure design, easy adjustment of technical parameters, and improvement of contact and flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

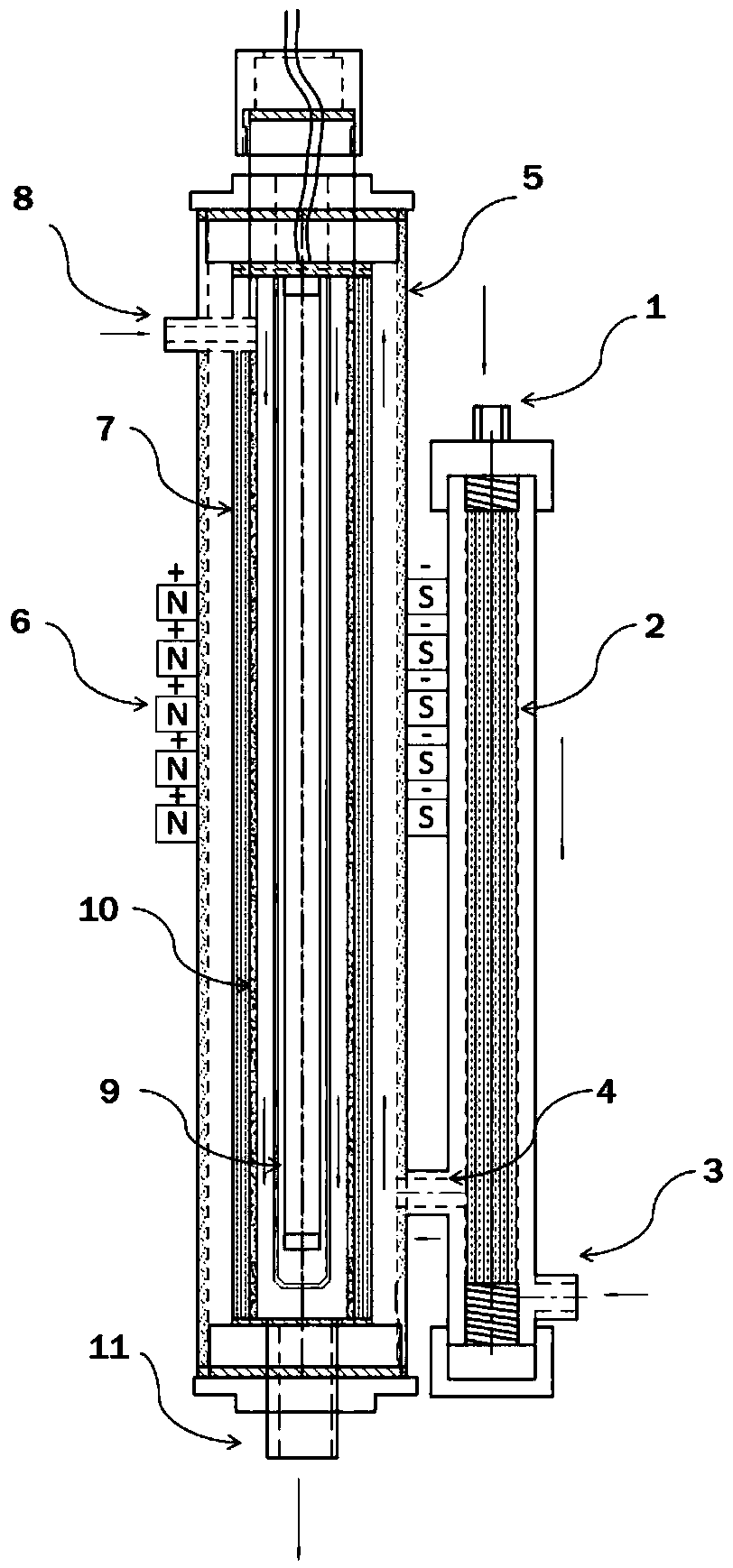

[0042] Use coking wastewater figure 2 When the shown ultraviolet strong oxygen reaction device is processed, first connect the pressure equipment (such as pressure tank, transfer pump, etc.) to the water inlet 1, and transport the coking wastewater to be treated into the filter to filter the membrane 2, for example, ultrafiltration Membrane, the ultrafiltration method is used to filter and remove the suspended particles with a diameter of more than 2nm in the coking wastewater. After ultrafiltration, the purified water is output through the filter outlet 4. At the same time, the primary oxidation state active agent is used by pressure equipment (such as pressure tanks, transfer pumps, etc.) ) The purified water is transported into the filter and ultrafiltration, and enters the ultraviolet strong oxygen reactor through the filter outlet 4 at the same time, and the filter is connected to the ultraviolet strong oxygen reactor by the filter outlet 4; in this embodiment, it is added ...

Embodiment 2

[0049] The difference between Example 2 and Example 1 is that the treatment object is high-salt wastewater, and the primary oxidation state active agent selected is 0.10mmol / L K 2 SO 4 , The microporous electrophilic medium is Fe 2 O 3 , The intermediate oxidation state active agent is 0.08mmol / L CH 3 COOOH, the chemical composition of the nanocrystalline spike catalyst is Bi 2 O 3 , The other processing procedures are the same as the embodiment 1. The treatment effects of traditional ozone oxidation technology and ultraviolet strong oxygen technology are shown in the following table:

[0050] High salt wastewater

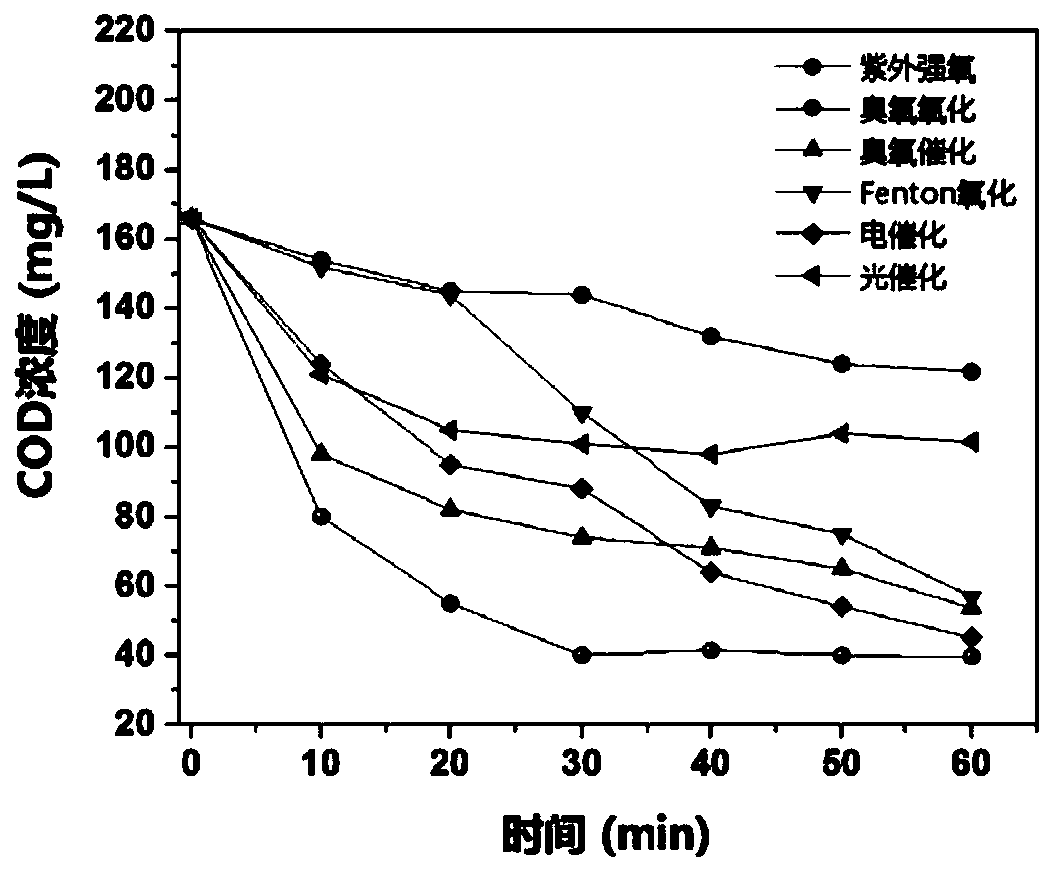

[0051] It can be obtained from the table to characterize the COD of the water quality index of high-salt wastewater Cr , NH 3 The content of -N, oil content, and SS are all significantly decreased, and the conductivity of the effluent of high-salt wastewater also decreases relative to the raw water. In addition, such as Figure 4 The shown ultraviolet strong oxygen ...

Embodiment 3

[0053] The difference between Example 3 and Example 1 is that the treatment object is polymer-containing wastewater, and the primary oxidation state active agent selected is 0.07mmol / L H 2 SO 4 , The microporous electrophilic medium is NiO, the intermediate oxidation state active agent is 0.22mmol / L H 2 O 2 , The chemical composition of the nanocrystalline spike catalyst is In 2 O 3 , The electromagnetic field excitation source is a 12V alternating electric field; the ultraviolet radiation excitation source is a 20W UV-C ultraviolet lamp. The other processing procedures are the same as in Example 1. The treatment effects of traditional Fenton oxidation technology and ultraviolet strong oxygen technology are shown in the table below:

[0054] Polymer containing wastewater

[0055] It can be obtained from the table to characterize the COD of the water quality index of wastewater containing polymer C The obvious decrease indicates that after the method of the present invention is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com