Denitrification method for coking wastewater

A technology for coking wastewater and denitrification, applied in chemical instruments and methods, water pollutants, multi-stage water treatment, etc. The effect of land area and operation cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

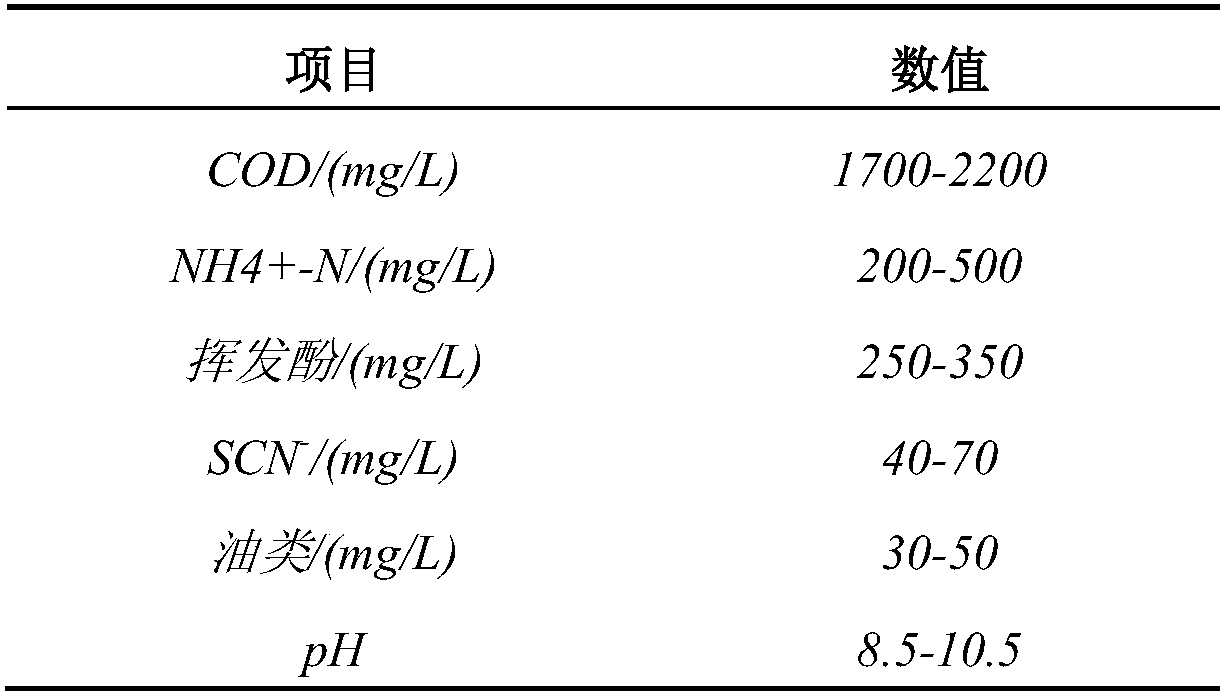

[0036] The coking wastewater was taken from a large coking plant. The water quality is shown in Table 1. The pH value of the wastewater was adjusted by adding sulfuric acid and phosphoric acid, and phosphorus was added to adjust the nutrient composition of the wastewater according to C:N:P=200:50:1. The sludge is taken from the aeration tank of the coking wastewater biochemical treatment system, and it is statically settled for 30 minutes to remove the sludge with poor settling performance and suspended impurities.

[0037] The temperature is controlled at (35±1)°C, the dissolved oxygen is 2.0-3.0 mg / L, and the first-stage ae...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com