Piezoelectric ceramic material with high voltage electric response and high Curie temperature and preparation method thereof

A piezoelectric ceramic and high voltage technology, which is applied in the field of lead-free textured piezoelectric ceramic materials and its preparation, can solve the problems of inability to obtain high positive piezoelectric effect and high Curie temperature, etc., to ensure optimal selection Effects of orientation, high Curie temperature, and high piezoelectric response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

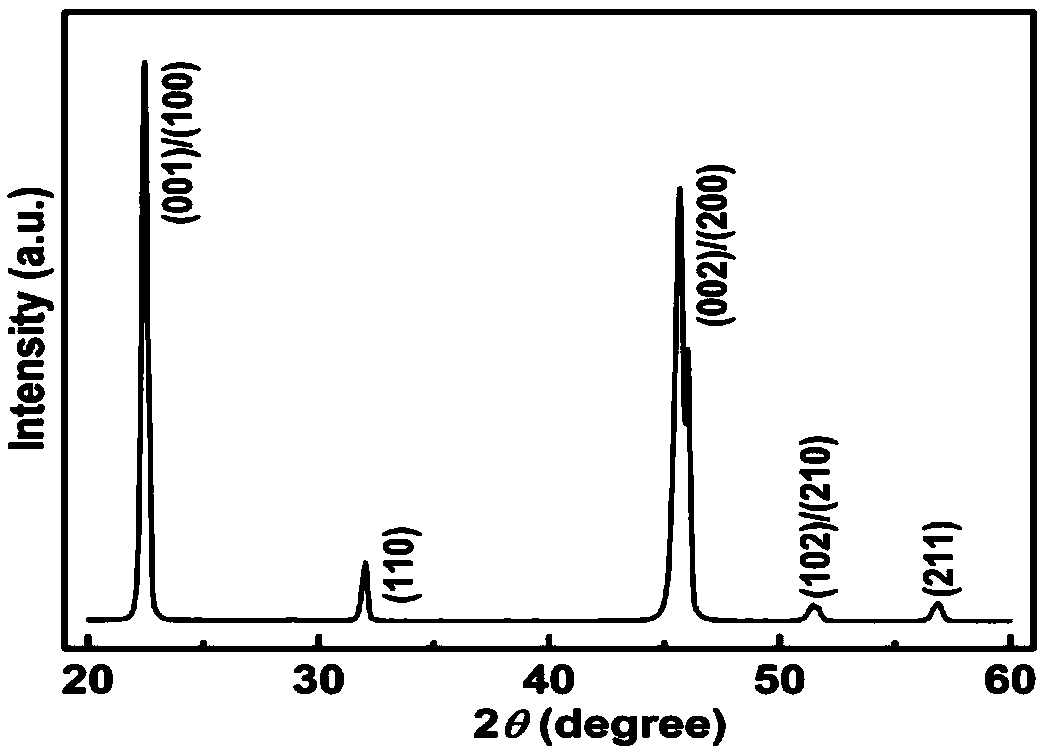

[0035] The preparation method of the piezoelectric ceramic material with high piezoelectric response and high Curie temperature adopts the following steps:

[0036] (1) Preparation of powder base material: with K 2 CO 3 , Na 2 CO 3 ,Nb 2 o 5 ,Sb 2 o 3 ,ZrO 2 , Bi 2 o 3 As the raw material, after drying the raw material, weigh it according to the above stoichiometric ratio, ball mill the raw material and mix it evenly, then pre-calcine at 850-900°C for 3-6h, then carry out secondary ball milling, drying, and sieving to obtain the powder Binder;

[0037] (2) NaNbO was prepared by two-step molten salt method 3 sheet template, using the following steps:

[0038] (2-1) Precursor Bi prepared by molten salt method 2.5 Na 3.5 Nb 5 o 18 : (6-7): (6-7): (9-10) mixed raw material Bi according to the mol ratio 2 o 3 、Na 2 CO 3 , and TiO 2 , then add NaCl as a molten salt, the quality of NaCl is 1.1-1.5 times the total mass of the above three raw materials, ball mill t...

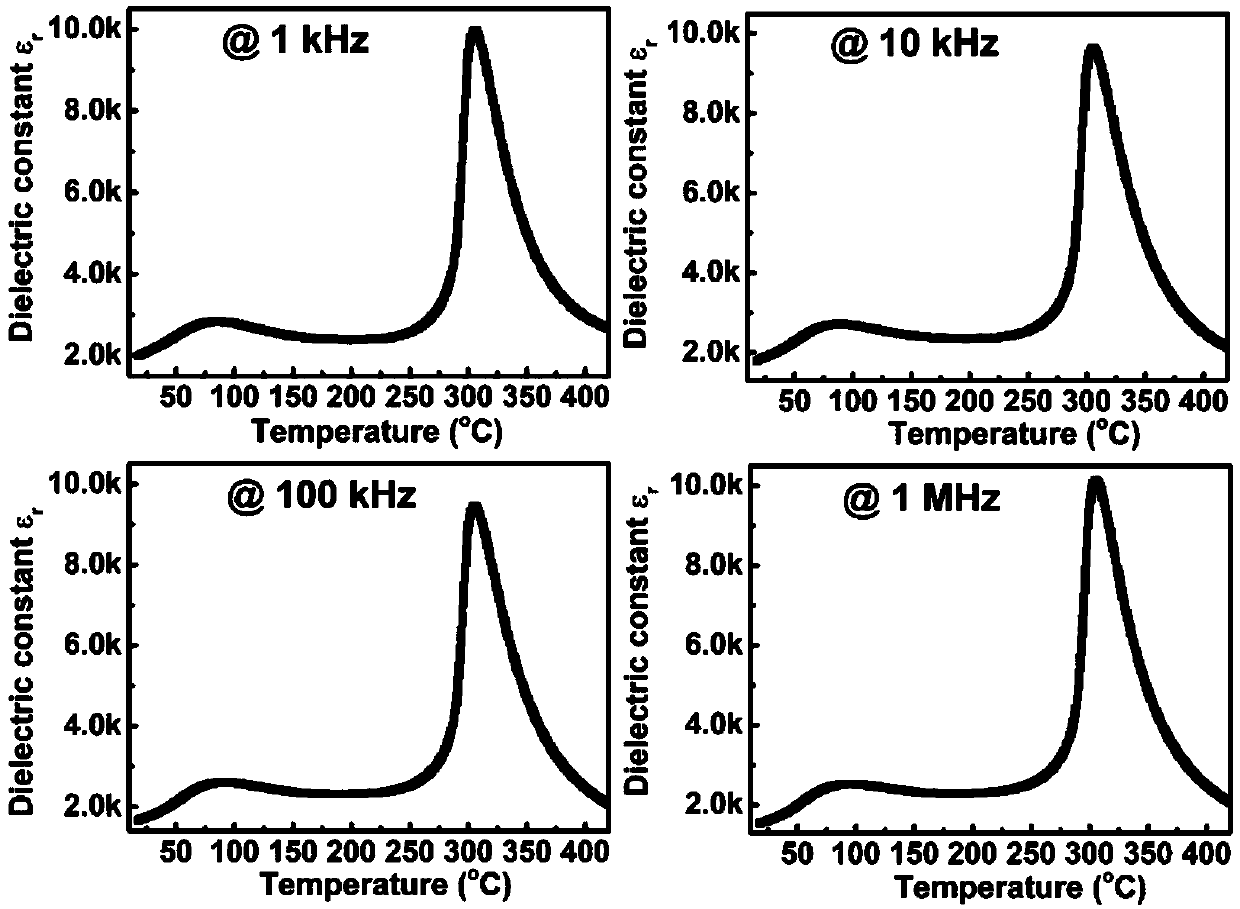

Embodiment 1

[0048] 1. 0.97 (K 0.48 Na 0.52 )(Nb 0.97 Sb 0.03 )O 3 -0.03Bi 0.5 (Na 0.8 K 0.2 ) 0.5 ZrO 3 Preparation of powder base material: weigh 5.1580g NaCO 3 , 6.5420g KCO 3 , 24.2175g Nb 2 o 5 , 0.8492g Sb 2 o 3 , 0.7468g ZrO 2 , 0.6992g Bi 2 o 3 As the raw material, put the raw material into a nylon tank, add absolute ethanol and zirconium balls, and mill for 24 hours; dry the evenly mixed raw material at 100°C, and then pre-fire it at 850°C for 5 hours; put the pre-fired powder in the grinder After grinding in a bowl, carry out secondary ball milling, and the ball milling time is 48 hours; after drying the slurry after the secondary ball milling at 100°C, grind it with a mortar and pass through a 200-mesh sieve to obtain a base material with uniform particle size. material.

[0049] 2. Weigh 10g of pre-synthesized 0.97(K 0.48 Na 0.52 )(Nb 0.97 Sb 0.03 )O 3 -0.03Bi 0.5 (Na 0.8 K 0.2 ) 0.5 ZrO 3 Base material, 0.2810g NaNbO 3 Template, 0.05g MnO 2 For po...

Embodiment 2

[0055] 1. 0.97 (K 0.48 Na 0.52 )(Nb 0.96 Sb 0.04 )O 3 -0.03Bi 0.5 (Na 0.8 K 0.2 ) 0.5 ZrO 3 Preparation of powder base material: weigh 5.1580g NaCO 3 , 6.5420g KCO 3 , 23.9596g Nb 2 o 5 , 1.1322g Sb 2 o 3 , 0.7468g ZrO 2 , 0.6992g Bi 2 o 3 As the raw material, put the raw material into a nylon tank, add absolute ethanol and zirconium balls, and mill for 24 hours; dry the evenly mixed raw material at 100°C, and then pre-fire it at 850°C for 5 hours; put the pre-fired powder in the grinder After grinding in a bowl, perform secondary ball milling for 48 hours; dry the slurry after secondary ball milling at 100°C, grind it with a mortar and pass through a 200-mesh sieve to obtain a base material with uniform particle size .

[0056] 2. Weigh 10g of pre-synthesized 0.97(K 0.48 Na 0.52 )(Nb 0.96 Sb 0.04 )O 3 -0.03Bi 0.5 (Na 0.8 K 0.2 ) 0.5 ZrO 3 Base material, 0.2805g NaNbO 3 Template, 0.05g MnO 2 For powder, weigh toluene and absolute ethanol with a ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com