A kind of thermal insulation and environmental protection wall coating and preparation method thereof

A thermal insulation and environmental protection technology, applied in the direction of epoxy resin coating, coating, etc., can solve the problems of small thermal conductivity, lower thermal conductivity of coating, poor thermal insulation performance, etc., and achieve the effect of small thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

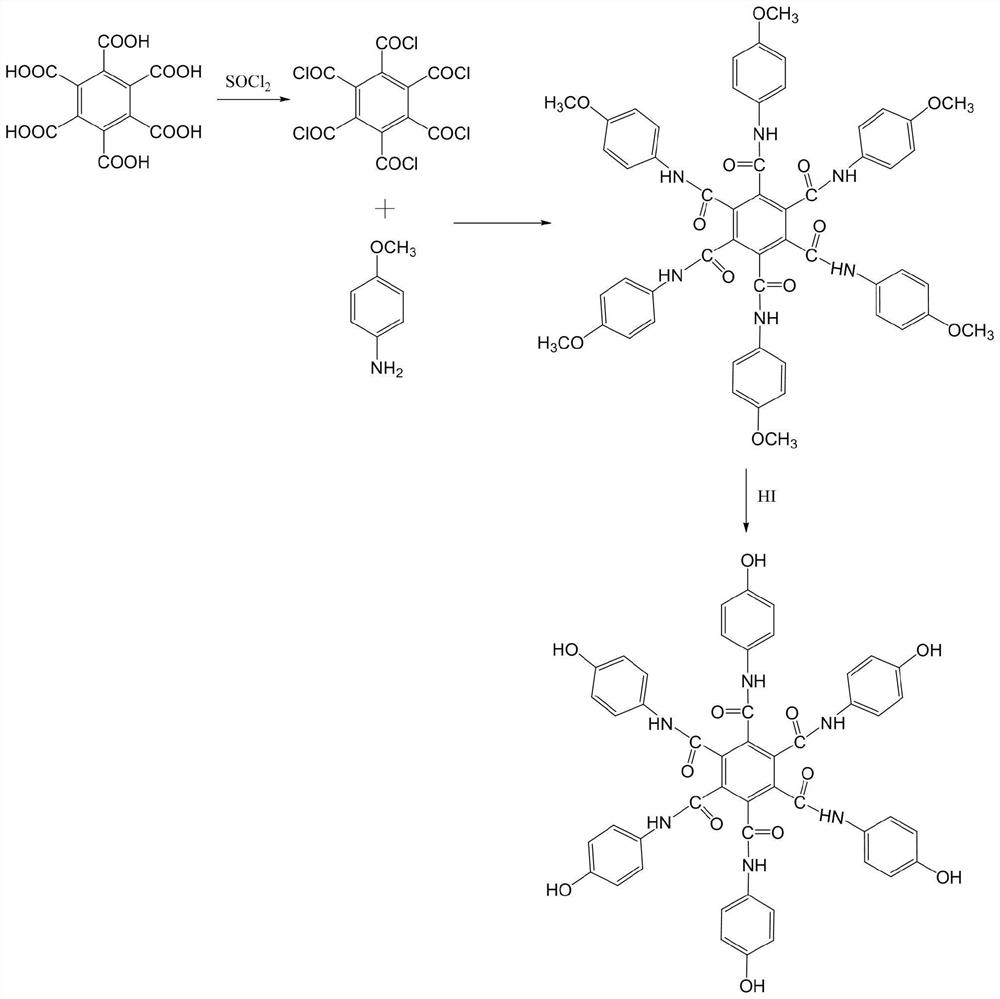

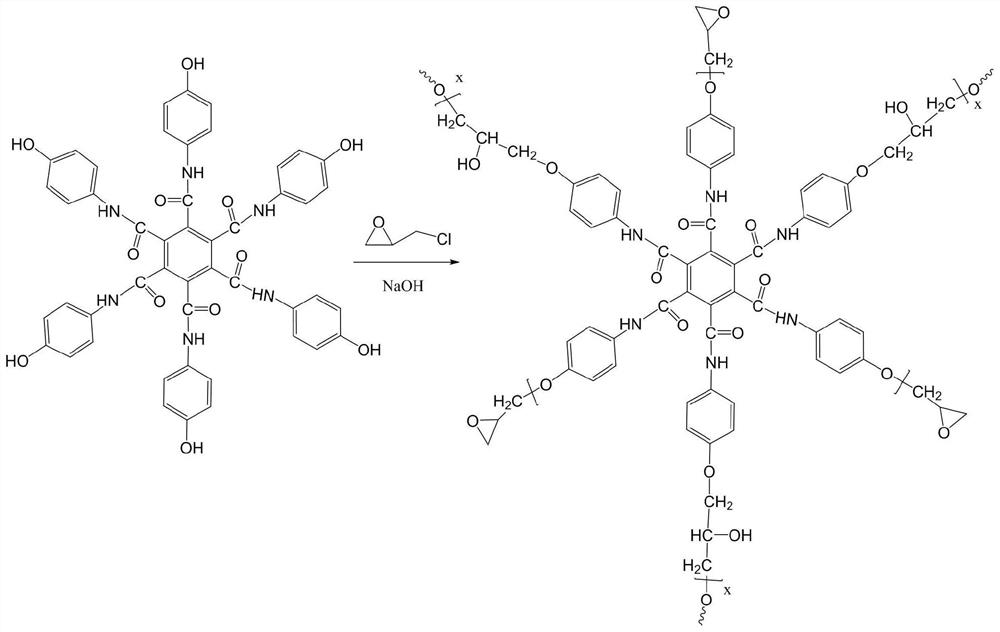

[0031] The concrete preparation process of water-soluble epoxy resin is as follows:

[0032] ① Add 1 kg of mellitic acid to 2.31 kg of thionyl chloride, raise the temperature to 80°C for reflux reaction for 10-12 hours, and then evaporate at 80°C to obtain melliticoyl chloride;

[0033] ②Weigh 1.95kg of p-aminoanisole and add it into 20L of dichloromethane, and add 0.55kg of triethylamine to it at the same time, then control the reaction temperature at 10°C, slowly add 1kg of melliticoyl chloride prepared in step ① to it, After the dropwise addition was complete, the reaction was carried out at constant temperature for 5 hours, and then vacuum distillation was carried out to obtain the product A;

[0034] ③Add 1kg of the product A prepared in step ② into 20L dimethyl sulfoxide, raise the temperature to 140°C and reflux, then add 2.01kg of hydroiodic acid dropwise into the reaction vessel, stir vigorously while adding, and after the addition is complete, After washing with sat...

Embodiment 2

[0037] The concrete preparation process of water-soluble epoxy resin is as follows:

[0038] ① Add 1 kg of mellitic acid to 1.1 kg of thionyl chloride, raise the temperature to 80°C for reflux reaction for 10-12 hours, and then evaporate at 80°C to obtain mellitic acid chloride; among them, mellitic acid and thionyl chloride are in molar ratio It is added in a ratio of 1:3, so that there are only three carboxybenzoyl chlorides in the prepared mellitic hexayl chloride;

[0039] ②Weigh 1.95kg of p-aminoanisole and add it into 20L of dichloromethane, and add 0.55kg of triethylamine to it at the same time, then control the reaction temperature at 10°C, slowly add 1kg of melliticoyl chloride prepared in step ① to it, After the dropwise addition was complete, the reaction was carried out at constant temperature for 5 hours, and then vacuum distillation was carried out to obtain the product A;

[0040] ③Add 1kg of the product A prepared in step ② into 20L dimethyl sulfoxide, raise t...

Embodiment 3

[0044] The specific preparation process of phase-change heat-insulating microspheres is as follows:

[0045] Step 1: Add 1kg of paraffin into the reaction vessel, heat up to 80°C and melt, add 0.23kg of diatomaceous earth to it, stir and mix at a constant temperature for 2-3 hours. When mixing, the paraffin is impregnated in diatomite, then filtered while hot, and the modified diatomite obtained after filtration is dried at room temperature;

[0046] Step 2: Add 1 kg of the modified diatomite prepared in step 1 into a small ball mill, and at the same time add 12 g of nanometer titanium dioxide therein, mix and grind for 30-40 minutes to obtain titanium dioxide composite diatomite;

[0047] Step 3: the water-soluble epoxy resin prepared by 3.4kg embodiment 1 is added in 25kg water, after stirring and dissolving, add the titanium dioxide composite diatomite prepared in 4.5kg step 2 wherein, stir and mix 3-5min, then at room temperature to Add 1.6kg of toluene-2,4-diisocyanate d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com