Environment-friendly filter stick and method for producing same

A kind of filter rod, environmental protection technology, applied in the direction of smoke oil filter element, application, tobacco, etc., can solve the production concept that does not conform to environmental protection and sustainable development, single structure of cigarette filter rod, limited capacity of harmful substances, etc. To achieve the effect of ensuring ventilation performance and filtering capacity, improving resource utilization and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

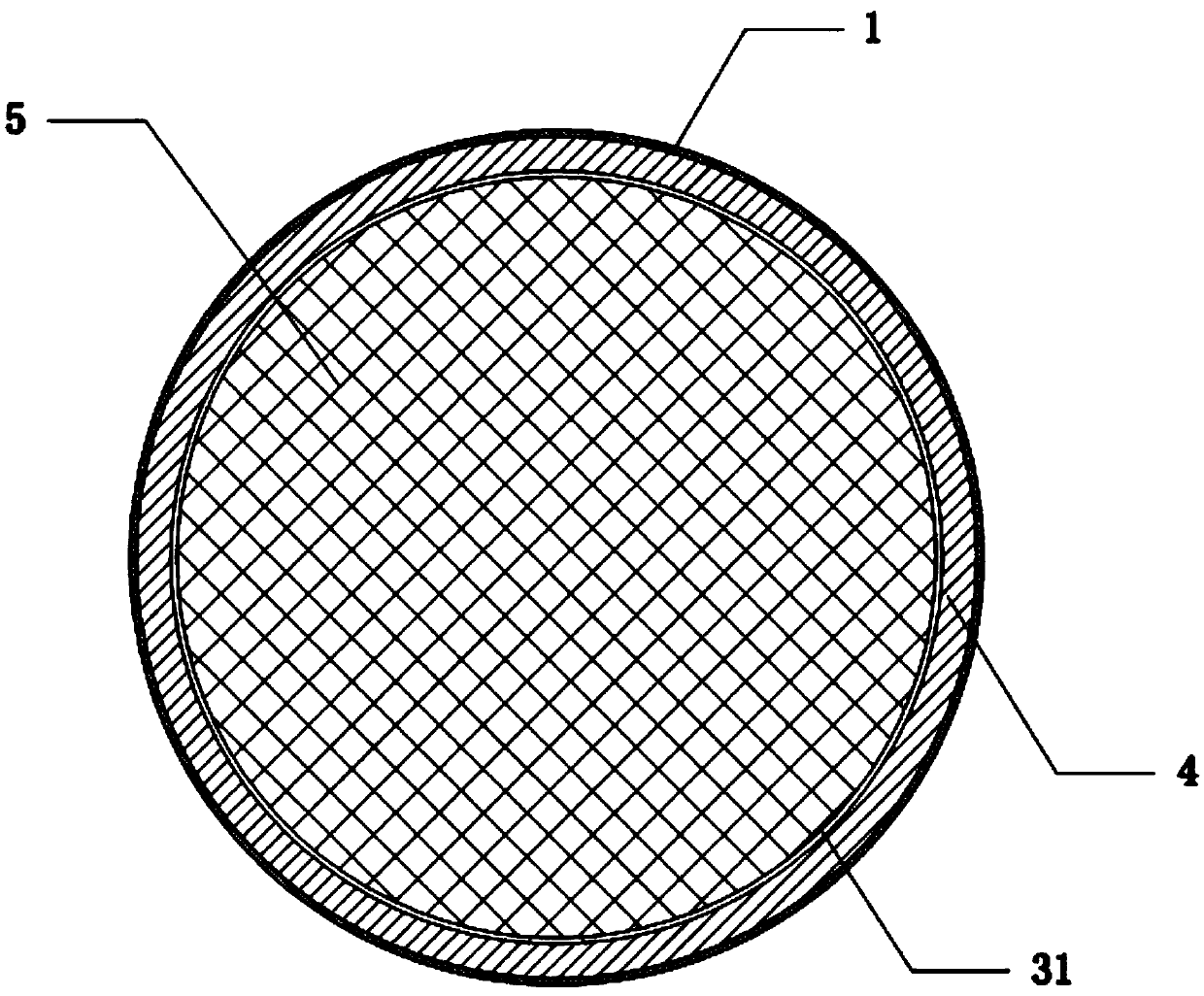

[0032] Specifically, the filter material 5 includes a fiber net and a hybrid filling material located in the fiber net, and the hybrid filling material includes HNTs, ferric oxide and sodium chloride crystals. The preparation method of the hybrid filling material comprises the following steps:

[0033] S1: Prepare 24-37g / L sodium chloride solution, 10-40g / L ferric chloride solution and 0.6%-0.9% polyvinyl alcohol solution;

[0034] S2: Mix the above-mentioned sodium chloride solution, ferric chloride solution and polyvinyl alcohol solution in a volume ratio of 5:1:0.4 to prepare a soaking solution;

[0035] S3: adding HNTs to the soaking solution in a weight ratio of 1:5 to the soaking solution and stirring, then adjusting the pH to 8-9 with 14% ammonia water, and then continuing to stir for 3 hours;

[0036] S4: The reaction product is separated by filtration, dried, ground, and calcined at 400° C. for 2 hours, so that ferric oxide is attached to the surface of HNTs, and sod...

Embodiment

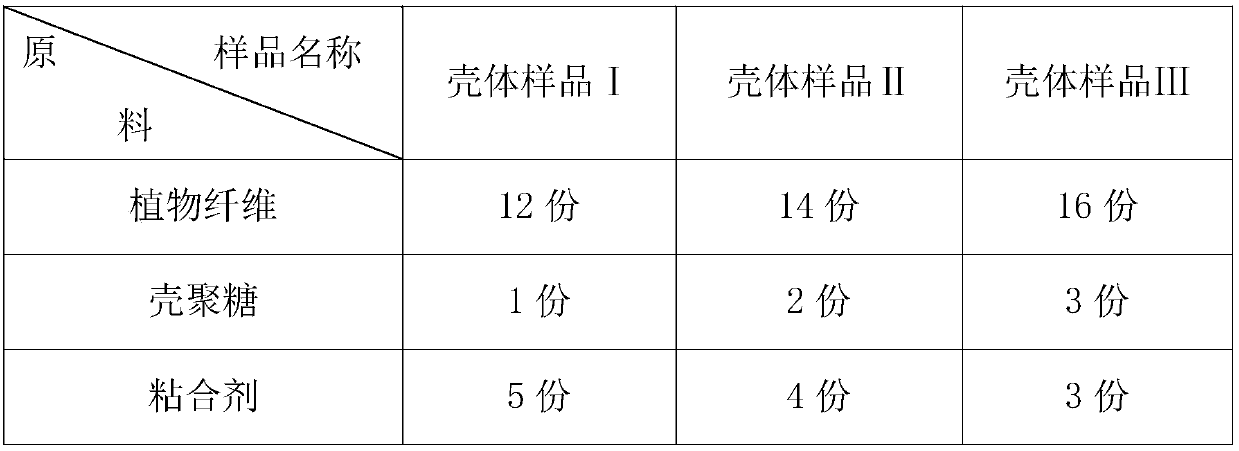

[0047] Prepare three shell 4 samples according to the following proportions:

[0048]

[0049] Preparation of hybrid filling material sample Ⅰ:

[0050] 1. Prepare 24g / L sodium chloride solution, 40g / L ferric chloride solution and 0.6% polyvinyl alcohol solution;

[0051]2. Mix the above-mentioned sodium chloride solution, ferric chloride solution and polyvinyl alcohol solution in a volume ratio of 5:1:0.4 to prepare the soaking solution;

[0052] 3. Add HNTs to the soaking solution at a weight ratio of 1:5 and stir, then adjust the pH to 9 with 14% ammonia water and continue stirring for 3 hours;

[0053] 4. The reaction product was separated by filtration, dried, ground, and calcined at 400° C. for 2 hours to obtain hybrid filling material sample I.

[0054] Preparation of hybrid filling material sample II:

[0055] 1. Prepare 37g / L sodium chloride solution, 10g / L ferric chloride solution and 0.9% polyvinyl alcohol solution;

[0056] 2. Mix the above-mentioned sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com