Preparation method for graphene

A graphene, oxygen source technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problem that the theoretical value is very different, it is difficult to repeatably, efficiently, safely and batch prepare graphene, and it is difficult to effectively improve graphene. Crystal domains and other problems, to achieve the effect of safe oxygen supply and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

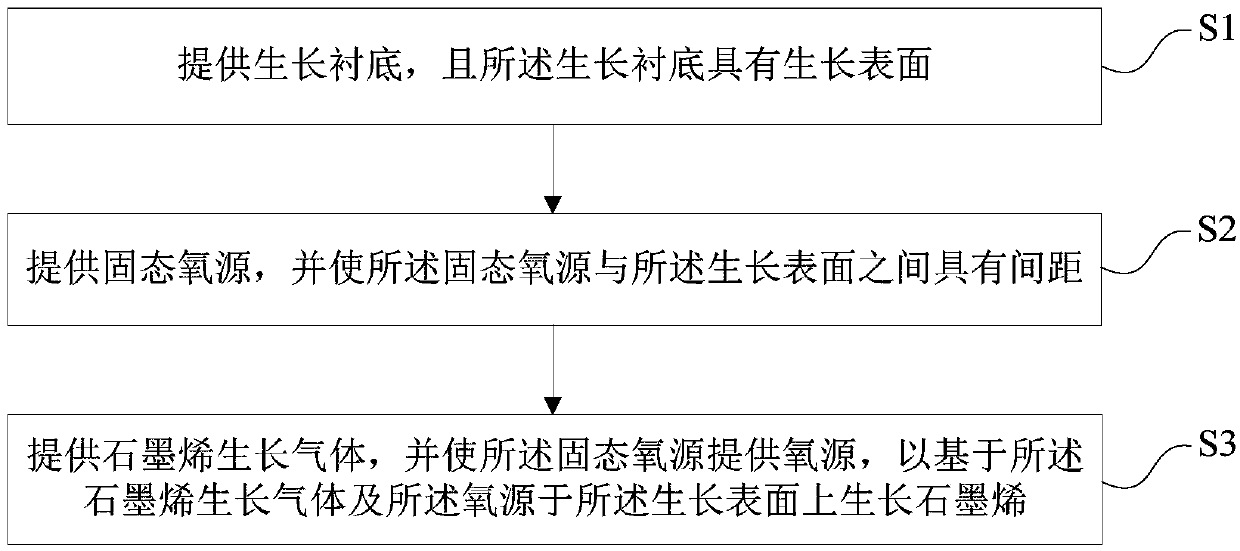

[0037] like Figure 1-6 As shown, the present invention provides a preparation method of graphene, and the preparation method comprises the following steps:

[0038] providing a growth substrate, and the growth substrate has a growth surface;

[0039] providing a solid-state oxygen source with a spacing between the solid-state oxygen source and the growth surface; and

[0040] A graphene growth gas is provided and the solid state oxygen source is caused to provide an oxygen source to grow graphene on the growth surface based on the graphene growth gas and the oxygen source.

[0041] The above-mentioned order of steps can be adjusted according to the actual process, and is not limited to the above-mentioned order.

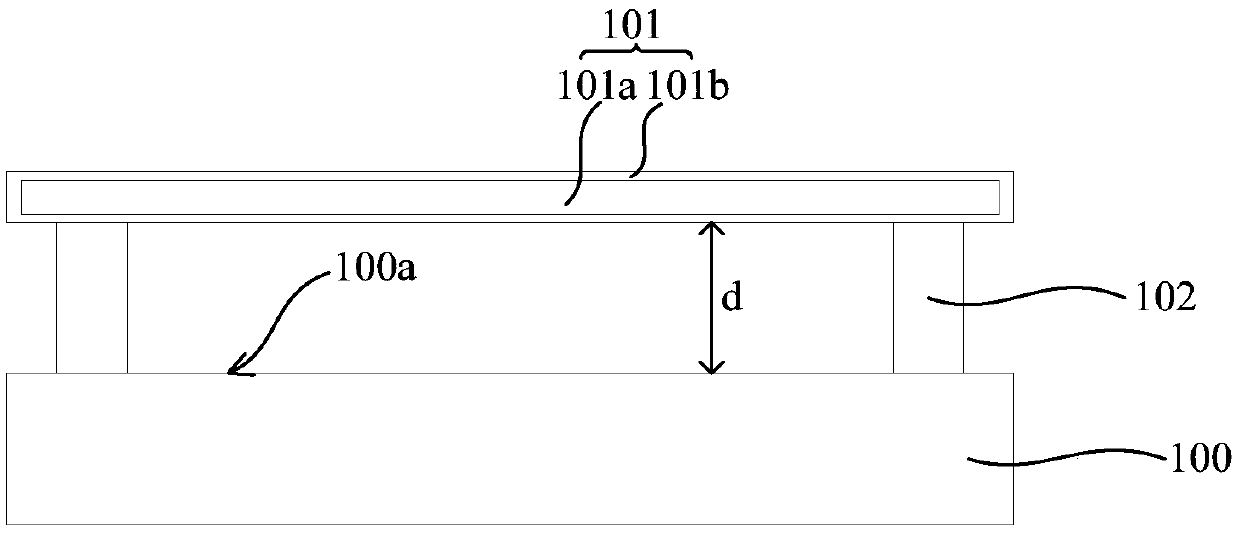

[0042] First, as figure 1 in S1 and figure 2 , 5 As shown, a growth substrate 100 is provided, and the growth substrate 100 has a growth surface 100a;

[0043] As an example, the material of the growth substrate 100 includes metal.

[0044] As an example, th...

Embodiment 1

[0077] The present embodiment provides a method for remote oxygen supply through copper oxide during CVD graphene growth, which specifically includes:

[0078] 1) oxidize a piece of clean copper foil 101a at high temperature in the air to form an oxide layer 101b on the surface as an oxide of copper, i.e. the solid oxygen source 101;

[0079] 2) Place the oxidized copper foil, that is, the solid-state oxygen source 101 on the opposite side of the growth substrate 100, with a quartz plate in the middle and the pillars 102 to separate, as shown in figure 2 shown, the distance between the copper oxide and the growth substrate is about 2 mm;

[0080] 3) The growth substrate and copper oxide and a piece of substrate not covered with copper oxide are used as comparative samples, and they are put into the heating area of the quartz tube furnace together, evacuated, and 1000sccm of argon gas is introduced to normal pressure , open the air outlet of the cavity, and continue to intr...

Embodiment 2

[0086] The present embodiment provides a method for remote oxygen supply through copper oxide during CVD graphene growth, which specifically includes:

[0087] 1) oxidize a piece of clean copper foil 101a at high temperature in the air to form an oxide layer 101b on the surface as an oxide of copper, i.e. the solid oxygen source 101;

[0088] 2) Place the oxidized copper foil on the growth substrate 100, such as Figure 5 As shown, the graphene growth region 103 is a 0-1 cm region away from the copper oxide, and the graphene growth region 104 is a 1-2 cm region away from the copper oxide;

[0089] 3) Put the placed growth substrate and copper oxide into the heating area of the quartz tube furnace, evacuate, pass 1000sccm argon gas to normal pressure, open the gas outlet of the cavity, and continue to pass 1000sccm argon gas to make the quartz cavity maintain normal pressure inside the body;

[0090] 4) Heating to 1000°C, feeding 1sccm CH4 and 20sccmH2, and maintaining for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com