Preparation method of light curing molding potassium-sodium niobate leadless piezoelectric ceramics

A technology of light-curing molding and potassium sodium niobate, which is applied in the field of piezoelectric ceramics, can solve problems such as inability to realize complex structures, complex processing techniques, and damage, and achieve excellent electrical properties, low viscosity, and high light activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

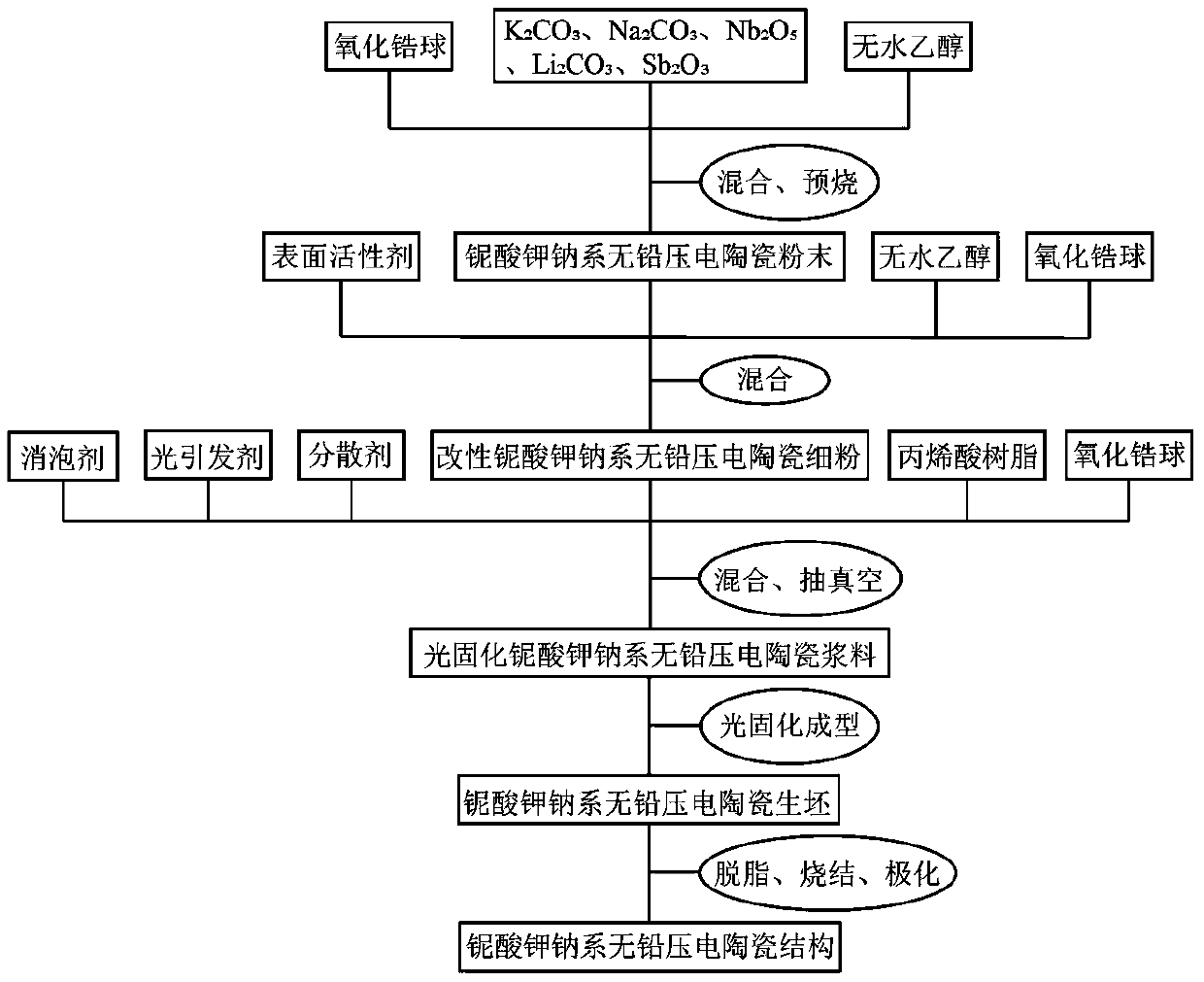

[0026] Preliminary chemical formula is K 0.46 Na 0.5 Li 0.04 Nb 0.95 Sb 0.05 o 3 Potassium sodium niobate series lead-free piezoelectric ceramic powder, the powder can be purchased from the market or can be obtained according to the preparation methods well known to those skilled in the art, and can also be prepared by the following method: According to chemical formula K 0.46 Na 0.5 Li 0.04 Nb 0.95 Sb 0.05 o 3 The atomic ratio of each element in the formula, weigh a certain mass of K 2 CO 3 、Na 3 CO 3 , Nb 2 o 5 , Li 2 CO 3 and Sb 2 o 3Pour the raw materials into the ball mill jar respectively, add the grinding medium absolute ethanol and zirconia grinding balls, wet the mixture at 250rpm for 24 hours, dry the intermediate to obtain the intermediate, and pre-calcine the intermediate at 900°C for 4 hours , and crushed with a mortar to obtain 0.46 Na 0.5 Li 0.04 Nb 0.95 Sb 0.05 o 3 Potassium sodium niobate based lead-free piezoelectric ceramic powder wi...

Embodiment 2

[0043] Preliminary chemical formula is K 0.46 Na 0.5 Li 0.04 Nb 0.95 Sb 0.05 o 3 Potassium sodium niobate-based lead-free piezoelectric ceramic powder, which can be purchased from the market or can be obtained according to a preparation method well known to those skilled in the art, or can be prepared by the method described in Example 1.

[0044] Weigh a certain mass of potassium sodium niobate lead-free piezoelectric ceramic powder, and weigh a surfactant whose mass is 1% of the mass of the ceramic powder, pour it into a ball mill jar, add grinding media absolute ethanol and zirconia Grinding balls, the mixture was ball milled at 350 rpm for 12 hours. This process not only breaks the ceramic particles to reduce the particle size of the powder, but also makes the surface active agent evenly adhere to the surface of the ceramic powder, so that the sodium potassium niobate series lead-free piezoelectric ceramic powder is modified. In this embodiment, polyethylene glycol o...

Embodiment 3

[0055] Preliminary chemical formula is K 0.46 Na 0.5 Li 0.04 Nb 0.95 Sb 0.05 o 3 Potassium sodium niobate-based lead-free piezoelectric ceramic powder, which can be purchased from the market or can be obtained according to a preparation method well known to those skilled in the art, or can be prepared by the method described in Example 1.

[0056] Weigh a certain mass of potassium sodium niobate lead-free piezoelectric ceramic powder, and weigh a surfactant whose mass is 1% of the mass of the ceramic powder, pour it into a ball mill jar, add grinding media absolute ethanol and zirconia Grinding balls, the mixture was ball milled at 350 rpm for 12 hours. This process not only breaks the ceramic particles to reduce the particle size of the powder, but also makes the surface active agent evenly adhere to the surface of the ceramic powder, so that the sodium potassium niobate series lead-free piezoelectric ceramic powder is modified. In this embodiment, polyethylene glycol o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com