Treatment process and treatment system for producing styrene high-concentration wastewater from methanol toluene

A high-concentration wastewater treatment technology, applied in the purification/separation of hydrocarbons, hydrocarbons, chemical instruments and methods, etc., can solve the problems of increasing the difficulty of wastewater treatment, reduce the difficulty of treatment, and realize the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

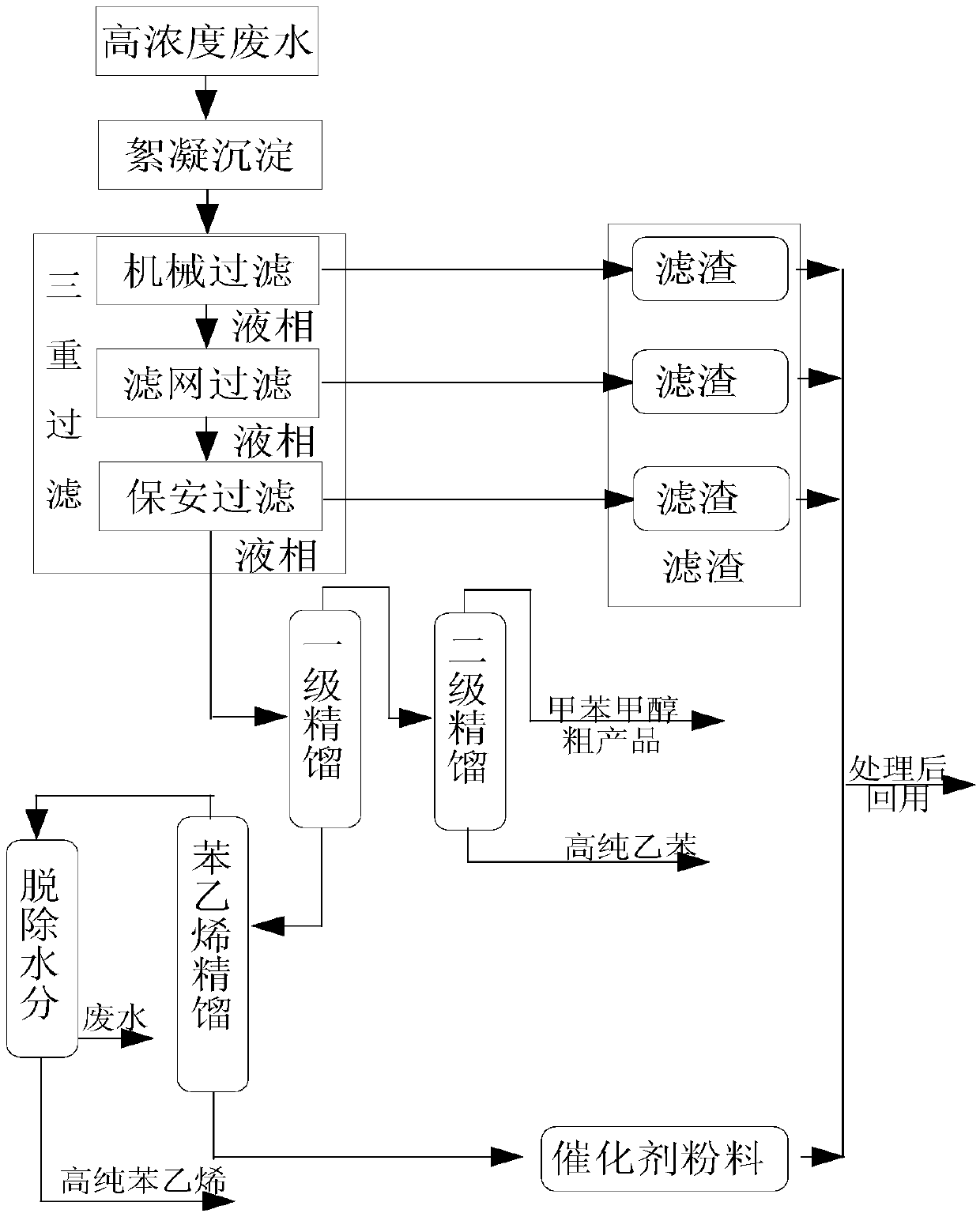

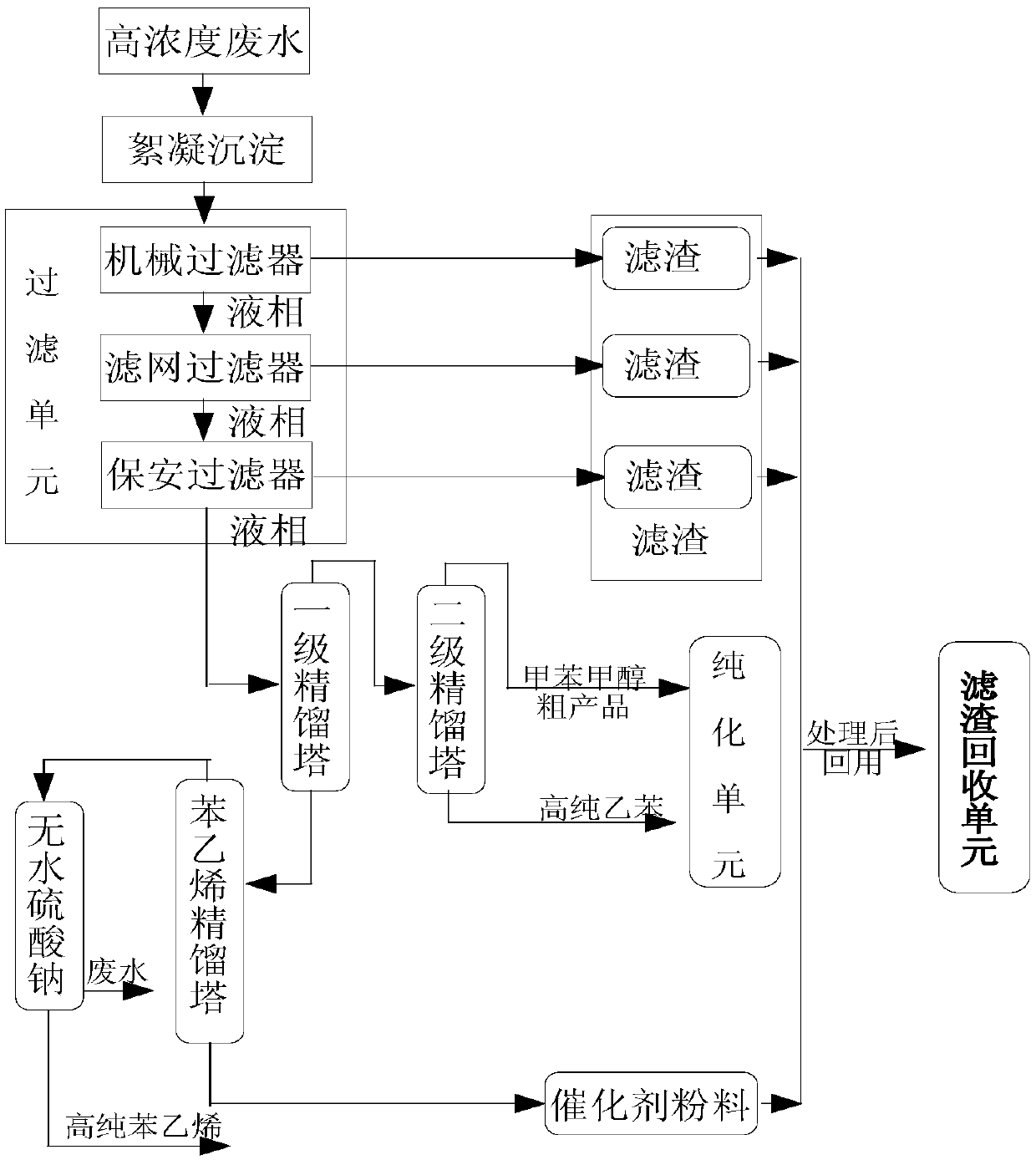

[0065] Add a certain amount of anionic polyacrylamide (molecular weight 6 million to 20 million) solution to the high-concentration styrene production wastewater from methanol toluene for flocculation and precipitation. The mass concentration of the polyacrylamide solution is 0.1wt%, and the addition ratio is 1:2000. The flocculation time is 4h, and the stirring speed is 200r / min.

[0066] The wastewater after flocculation and sedimentation is filtered through a mechanical filter with a filtration rate of 5m 3 / h, remove and collect the filter residue, the obtained filtrate enters the filter screen filter for filtration, the mesh number of the filter screen is 500 mesh, remove and collect the filter residue, and then send the obtained filtrate into a security filter with a precision of 5-20 μm for filtration and Send to the next stage, the activated sludge concentration of the obtained filtrate is 21.0mg / L.

[0067] The filtrate obtained from the security filter is separated ...

Embodiment 2

[0071] Add a certain amount of aluminum sulfate solution to styrene high-concentration wastewater produced by methanol toluene for flocculation and precipitation, the mass concentration of ferrous sulfate solution is 0.4wt%, the addition ratio is 1:5000, the flocculation time is 10h, and the stirring speed is 250r / min.

[0072] The wastewater after flocculation and sedimentation is filtered through a mechanical filter with a filtration rate of 20m 3 / h, remove and collect the filter residue, the obtained filtrate enters the filter screen filter for filtration, the mesh number of the filter screen is 200 mesh, remove and collect the filter residue, and then send the obtained filtrate into a security filter with a precision of 5-20 μm for filtration and Send to the next stage, the activated sludge concentration of the obtained filtrate is 20.2mg / L.

[0073] The filtrate obtained by the security filter is separated through a primary rectification tower. The top temperature of t...

Embodiment 3

[0077] Add a certain amount of ferric sulfate solution to carry out flocculation precipitation in methanol toluene production styrene high-concentration wastewater, the mass concentration of polyaluminum chloride solution is 0.25wt%, the addition ratio is 1:400, the flocculation time is 0.5h, and the stirring speed is 10r / min.

[0078] The wastewater after flocculation and sedimentation is filtered through a mechanical filter with a filtration rate of 1m 3 / h, remove and collect the filter residue, the obtained filtrate enters the filter screen filter for filtration, the mesh number of the filter screen is 1000 mesh, remove and collect the filter residue in the same way, and then send the obtained filtrate into a security filter with a precision of 5-20 μm for filtration and Send to the next stage, the activated sludge concentration of the obtained filtrate is 20.5mg / L.

[0079] The filtrate obtained by the security filter is separated through a primary rectification tower. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com