Water-based metallic flexible coating for plastics, and preparation method thereof

A water-based and plastic technology, applied in anti-fouling/underwater coatings, fire-resistant coatings, polyurea/polyurethane coatings, etc., can solve the problems of water-based plastic paint less, paint film peeling off, poor adhesion, etc., to achieve good durability, Lower film forming temperature and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

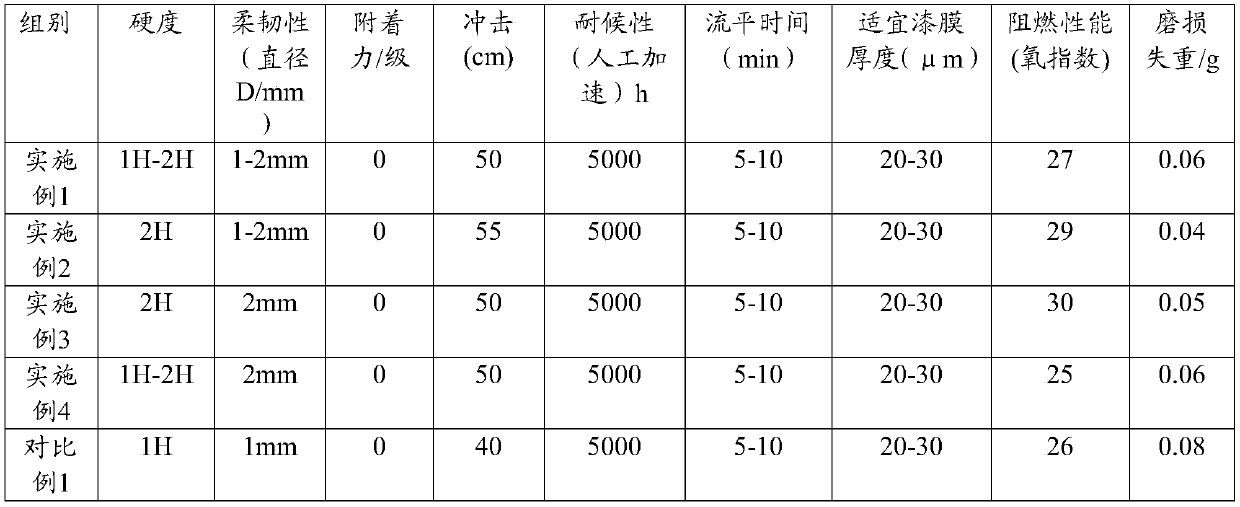

Embodiment 1

[0050] The embodiment of the present invention discloses a water-based plastic metal flexible coating, comprising the following components by weight: 10Kg of water-based elastic fluorocarbon emulsion, 30Kg of water-based hydroxyacrylic acid emulsion, 3Kg of polymethylsilsesquioxane, and 1Kg of nano-zirconia , Nano alumina 2Kg, pearl powder 5Kg, flame retardant 3Kg, nano zinc oxide 0.4Kg, adhesion promoter 0.15Kg, pH 8 dimethylethanolamine 0.15Kg, phosphate ester hydrophobic defoaming and antifoaming agent 941PL 0.2Kg, film-forming aid 3Kg, dispersant 0.4Kg, Tego-1000.4Kg, polyurethane thickener PS2020.8Kg, curing agent 10Kg, propylene glycol methyl ether acetate 3Kg, temperature-sensitive discoloration powder 3Kg and deionized water 8Kg. Wherein the film-forming aids are propylene glycol phenyl ether-based environment-friendly and clean-flavored film-forming aids AF and alcohol ester-12 film-forming aids, which are mixed according to the weight ratio of 1:1; wherein the dispers...

Embodiment 2

[0056] This embodiment discloses a water-based plastic metal flexible coating, comprising the following components in parts by weight: 15Kg of water-based elastic fluorocarbon emulsion, 40Kg of water-based hydroxy acrylic emulsion, 1Kg of polymethylsilsesquioxane, and 0.5Kg of nano-zirconia , Nano alumina 5Kg, pearl powder 8Kg, flame retardant 6Kg, nano zinc oxide 0.2Kg, adhesion promoter 0.1Kg, pH 9 multifunctional auxiliary agent AMP-950.2Kg, silicone defoamer BYK-0280.1 Kg, film-forming aid 5Kg, dispersant 0.3Kg, Tego-1000.5Kg, polyurethane thickener PS2020.5Kg, curing agent 20Kg, propylene glycol methyl ether acetate 2Kg, temperature-sensitive discoloration powder 5Kg and deionized water 10Kg. Wherein, the film-forming aids are propylene glycol phenyl ether-based environment-friendly and clean-flavored film-forming aids AF and alcohol ester-12 film-forming aids, which are mixed according to the weight ratio of 1:3; wherein the dispersant is polyester modified The polyphosp...

Embodiment 3

[0062] This embodiment discloses a water-based plastic metal flexible coating, comprising the following components in parts by weight: 5Kg of water-based elastic fluorocarbon emulsion, 50Kg of water-based hydroxy acrylic emulsion, 5Kg of polymethylsilsesquioxane, 2Kg of nano-zirconia, Nano Alumina 1Kg, Pearlescent Powder 3Kg, Flame Retardant 8Kg, Nano Zinc Oxide 0.5Kg, Adhesion Promoter 0.2Kg, pH 8 Multifunctional Auxiliary AMP-950.1Kg, Silicone Defoamer BYK0240.12Kg, Coalescence aid 2Kg, dispersant 0.5Kg, Tego-1000.3Kg, polyurethane thickener PS2021.0Kg, curing agent 5Kg, propylene glycol methyl ether acetate 5Kg, temperature-sensitive color-changing powder 1Kg and deionized water 5Kg. Wherein, the film-forming aids are propylene glycol phenyl ether-based environment-friendly and clean-flavored film-forming aids AF and alcohol ester-12 film-forming aids, which are mixed according to the weight ratio of 1:2; wherein the dispersant is polyester modified The polyphosphate disper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com