Zinc-silver-copper coating and preparation method thereof

A copper coating and coating technology, which is used in medical materials, dental implants, joint replacements and filling materials for human tissue defects and the antibacterial field of implant materials, which can solve problems such as poor histocompatibility and infection. , to achieve the effect of promoting wound healing, promoting healing, and improving immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

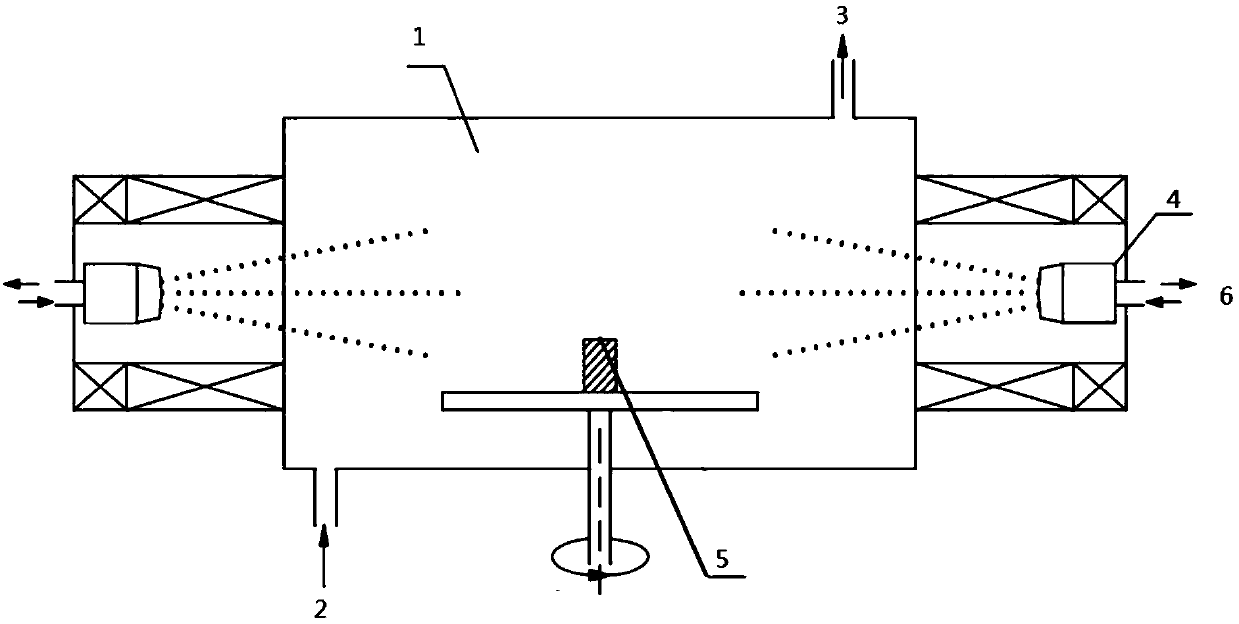

Embodiment 1

[0023] The titanium alloy (Ti-6Al-4V) original sheet is placed in the substrate 5 position in the furnace body 1 of the deposition chamber, and the zinc-silver-copper alloy target is placed in the target 4 position. The Ag content is 0.5%, the Cu content is 0.1%, and the ultimate vacuum (10 -5 Pa), the whole system was repeatedly purged 3 times with argon to ensure that the oxygen content was minimized. Set the bias voltage to 50V, the arc current to 30A, the duty cycle to 20%, and the working air pressure to 1×10 -2 Pa, the deposition time is 30 min, and the thickness of the deposited metal zinc-silver-copper layer is 1 μm. In order to determine the effect of the coating on promoting osteogenesis, an alkaline phosphatase (ALP) experiment was carried out. After culturing for 1 day, 4 days and 7 days, the color of the coating group was darker than that of the matrix group, indicating the activity of alkaline phosphatase in the coating group. higher than that of the matrix gro...

Embodiment 2

[0025] The porous titanium alloy (Ti-6Al-4V) original sheet is placed in the substrate 5 position in the furnace body 1 of the deposition chamber, and the zinc-silver-copper alloy target is placed in the target 4 position. The Ag content is 1.5%, the Cu content is 0.2%, and the ultimate vacuum (10 -5 Pa), the whole system was repeatedly purged 3 times with argon to ensure that the oxygen content was minimized. Set the bias voltage to 55V, the arc current to 40A, the duty cycle to 30%, and the working air pressure to 1×10 -2 Pa, the deposition time is 1 h, and the thickness of the deposited metal zinc-silver-copper layer is 2 μm. Since the substrate is directly placed on the surface of the substrate holder, the bottom of the substrate in contact with the substrate holder cannot deposit the coating. The substrate can be turned over, the bottom is turned up, and the coating is completely covered on the substrate surface. Metal wires can also be used to hang the porous substrate...

Embodiment 3

[0027] Put the planar pure titanium substrate into the substrate 5 position in the furnace body 1 of the deposition chamber, and place the zinc-silver-copper alloy target at the target 4 position. The Ag content is 3%, the Cu content is 0.8%, and the ultimate vacuum (10 -5 Pa), the whole system was repeatedly purged 3 times with argon to ensure that the oxygen content was minimized. Set the bias voltage to 60V, the arc current to 55A, the duty cycle to 40%, and the working air pressure to 1×10 -1 Pa, the deposition time is 1 h, and the thickness of the deposited metal zinc-silver-copper layer is 4 μm. After X-ray diffraction analysis and scanning electron microscope energy spectrum analysis, it is determined that the coating is zinc-silver-copper. Due to the low content of silver and copper, the X-ray spectrum can only show the diffraction information of metal zinc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com