Pre-lithiation method for lithium metal negative electrode protection

A lithium metal negative electrode, metal lithium technology, applied in the direction of electrode manufacturing, battery electrodes, electrode current collector coating, etc., can solve the problems of electrolyte consumption, uneven deposition, dead lithium, etc., to suppress the generation of lithium dendrites Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention can have the stable metal lithium negative electrode of protective film, and its preparation method generally comprises the following steps:

[0033] 1) Mix an organic polymer with good lithium ion transport properties and a binder to form a slurry and coat it on the current collector to prepare a pole piece containing an organic polymer;

[0034] 2) Assemble the pole piece made in step 1, metal lithium, and diaphragm into a battery, and add an appropriate electrolyte;

[0035] 3) Discharging the battery assembled in step 2, so that the metal lithium in the battery is evenly deposited on the current collector with the organic polymer;

[0036] 4) After discharging for a period of time, disassemble the battery in step 3, and take out the current collector containing organic polymer deposited with metallic lithium.

[0037]The surface that above-mentioned method obtains has the negative electrode of protective film, can be used for the assembly of f...

Embodiment 1

[0040] Vulcanized polyacrylonitrile, styrene-butadiene rubber, and carboxymethyl cellulose were uniformly mixed in a mass ratio of 90:5:5 with water as a solvent to form a slurry, which was coated on the current collector copper foil with a coating thickness of 10 μm. After the solvent evaporates, the copper foil is punched into a pole piece with a diameter of 16mm. Assemble the pole piece, diaphragm, and lithium metal into a button cell in an argon-protected glove box, and add 1,3-dioxygen at a concentration of 1M lithium bistrifluoromethanesulfonylimide and 1% mass concentration of lithium nitrate Pentacycline and ethylene glycol dimethyl ether (volume ratio 1:1) electrolyte.

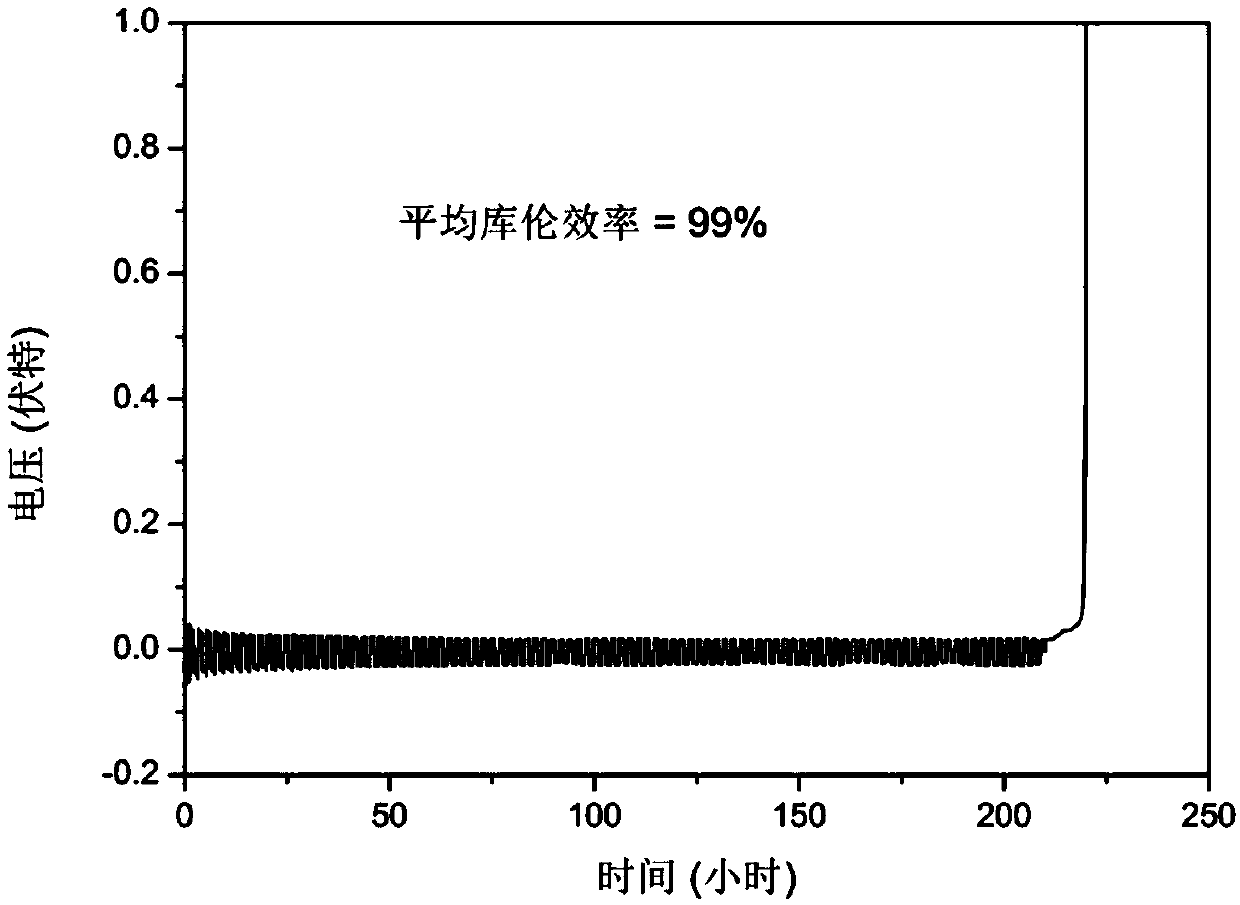

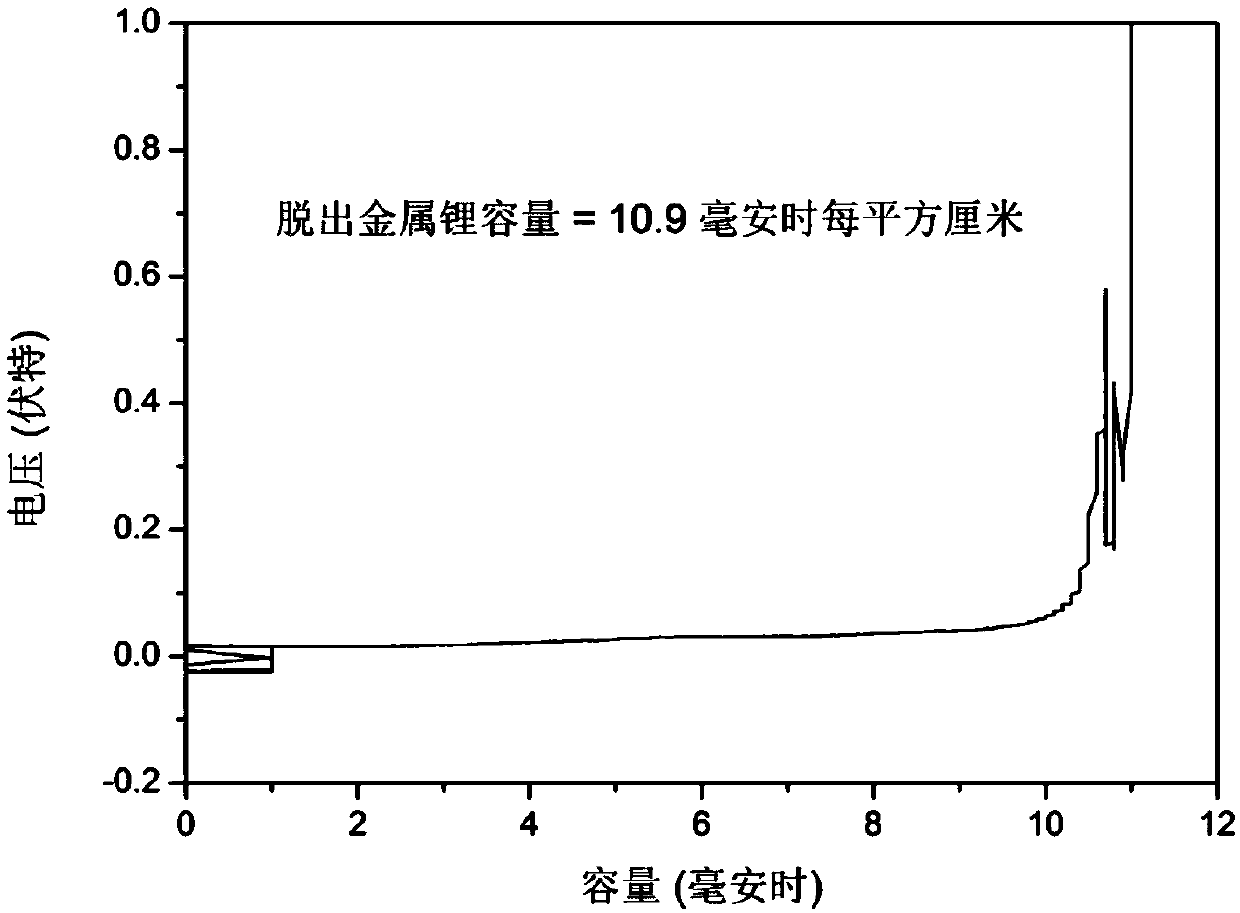

[0041] The button cell assembled by the above method was charged at 1mA / cm 2 Discharge for 11 hours at a current density of 11 mAh / cm on the surface of the current collector 2 of lithium metal.

[0042] After the discharge is completed, the above-mentioned button battery is disassembled, and the cu...

Embodiment 2

[0046] The prepared slurry is composed of vulcanized polyacrylonitrile and polyvinylidene fluoride at a ratio of 90:10, and N-methylpyrrolidone is used as a solvent. All the other are identical with example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com